Preparation method for positive electrode interface material of polymer thin film solar cell

A technology for solar cells and polymer films, applied in the field of solar cells, can solve problems such as water absorption affecting device stability, corrosion, and inability to form ohmic contacts, achieve excellent photovoltaic performance, increase hole collection efficiency, and reduce holes The effect of the output barrier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

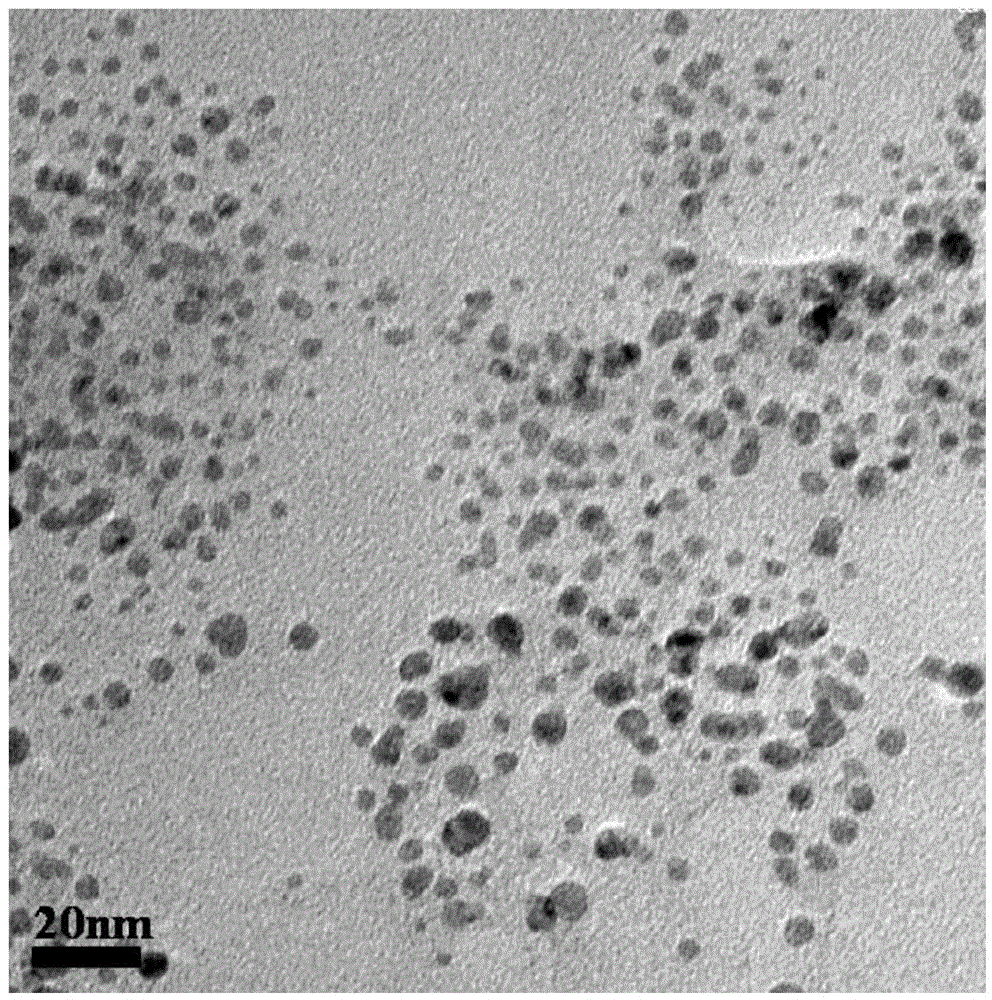

[0052] First, copper oxide nanoparticles were prepared by ultrasonic method, the specific steps are as follows:

[0053] (1) preparation concentration is the ethanol solution of the cupric chloride of 0.001 mol / liter;

[0054] (2) Adding 25% tetramethylammonium hydroxide by mass fraction therein to form a copper hydroxide suspension. Continue to stir the suspension for 40 minutes to ensure that the pH value of the solution does not change;

[0055] (3) Using a titanium rod with a diameter of 6 mm, apply 300 watts of energy to the suspension in the form of ultrasound for 40 minutes;

[0056] (4) The resulting suspension is centrifuged, then dispersed in ethanol, and prepared into an ethanol sol of copper oxide nanoparticles at a desired concentration.

[0057] Then, the mixed solution of the polymer and the fullerene derivative was prepared as follows: In an inert atmosphere glove box, 4 mg of poly[nitrogen-(1-octylnonyl)-2,7-carbazole-alternate-5 , 5-(4′,7′-bis-2-thienyl-2′...

Embodiment 2

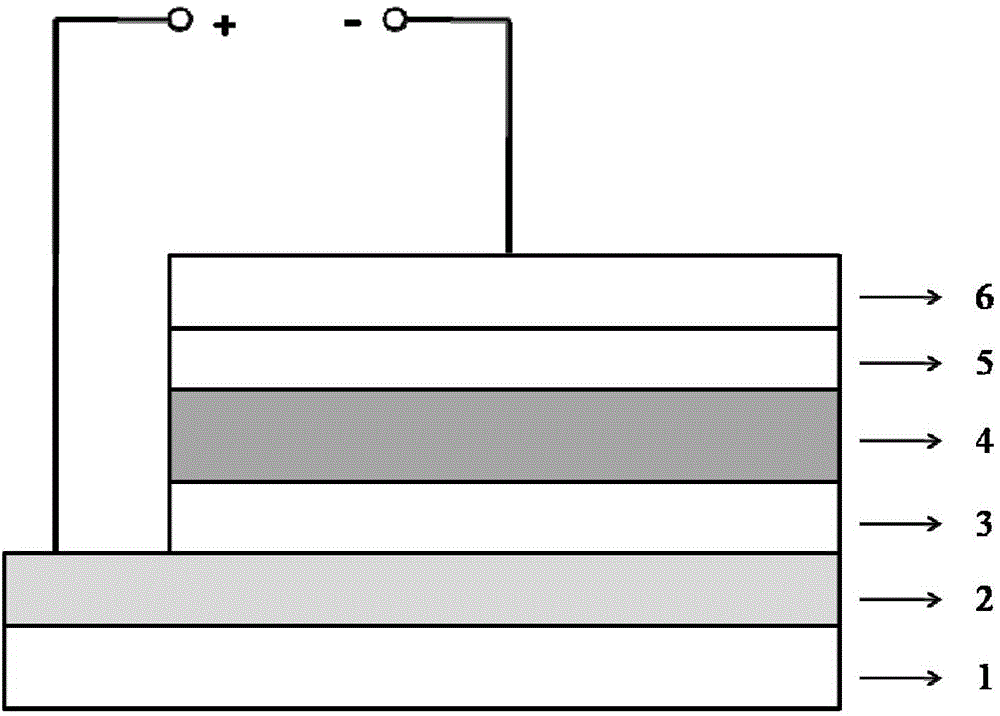

[0066] The preparation method of the copper oxide nanoparticles and the polymer solar cell is the same as that in Example 1, except that the rotational speed of the ethanol sol of the copper oxide nanoparticles is spin-coated at 400 rpm, and the thickness of the obtained film is 50 nanometers. Obtain polymer film solar cell, its device structure is: ITO (120nm) / copper oxide nanoparticle film (50nm) / PCDTBT:PC 70 BM(70nm) / LiF(1nm) / Al(80nm). The battery has an active area of 16 square millimeters. Treat in a UV-ozone atmosphere for 10 minutes.

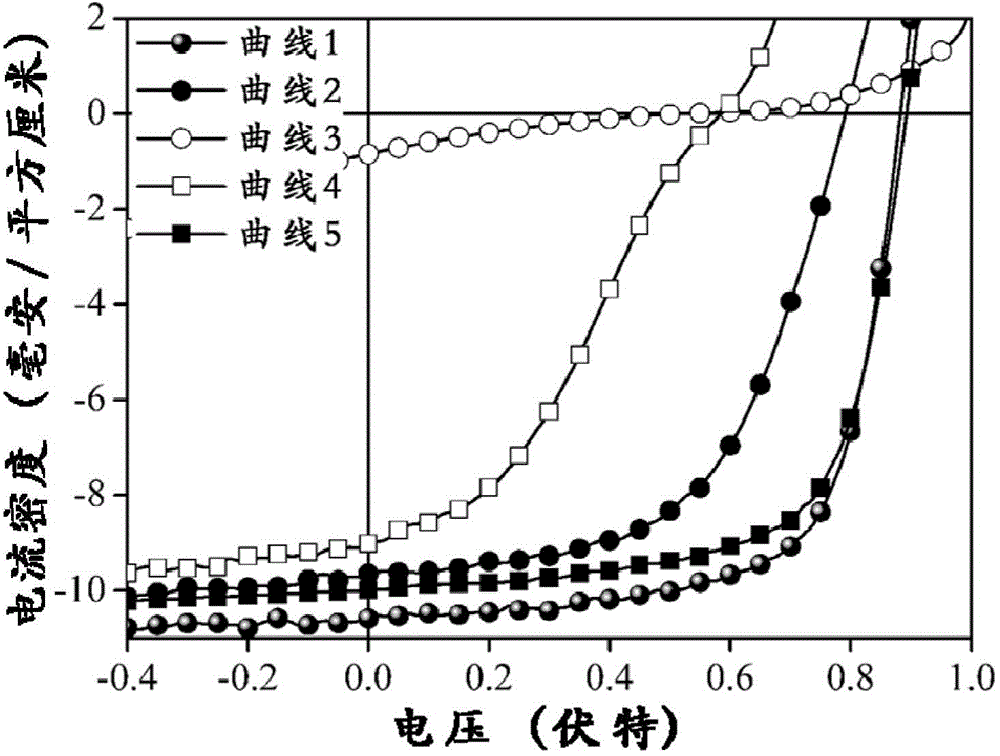

[0067] Test its current-voltage characteristic curve under 100 mW / cm2 AM 1.5G simulated sunlight, such as image 3 As shown in curve 2, its performance parameters are shown in Table 1.

Embodiment 3

[0069] The preparation method of the copper oxide nanoparticles and the polymer solar cell is the same as that in Example 1, except that the rotating speed of the ethanol sol of the copper oxide nanoparticles is spin-coated at 2500 rpm, and the thickness of the obtained film is 5 nanometers. Obtain polymer film solar cell, its device structure is: ITO (120nm) / copper oxide nanoparticle film (5nm) / PCDTBT:PC 70 BM(70nm) / LiF(1nm) / Al(80nm). The battery has an active area of 16 square millimeters. Treated in an ultraviolet ozone atmosphere for 30 minutes.

[0070] Test its current-voltage characteristic curve under 100 mW / cm2 AM 1.5G simulated sunlight, such as image 3 As shown in curve 3, its performance parameters are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| short-circuit current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com