Catalyst for selective hydrogenation of acetylene to ethylene and preparation method thereof

A technology for selective hydrogenation and ethylene production, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the problem of easy aggregation of active components and adverse active components Dispersion, catalytic efficiency decline and other problems, to achieve the effect of improving catalytic activity, accelerating desorption rate, and preventing active metal agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

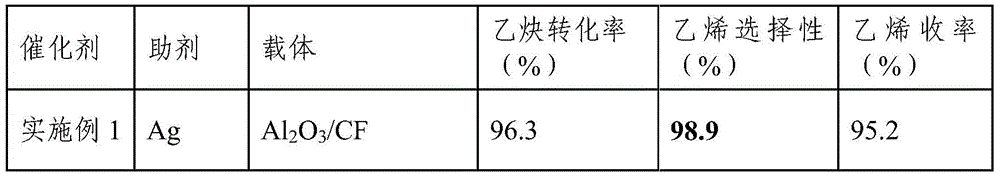

Embodiment 1

[0023] Embodiment 1 A kind of preparation method of acetylene selective hydrogenation ethylene catalyst

[0024] Proceed as follows:

[0025] (1) Take 10 g of PAN-based carbon fiber cloth (fiber diameter 10 μm), soak it in dilute nitric acid for 2 hours, take it out, rinse it with deionized water, and dry it at 80°C to obtain pretreated carbon fiber for later use;

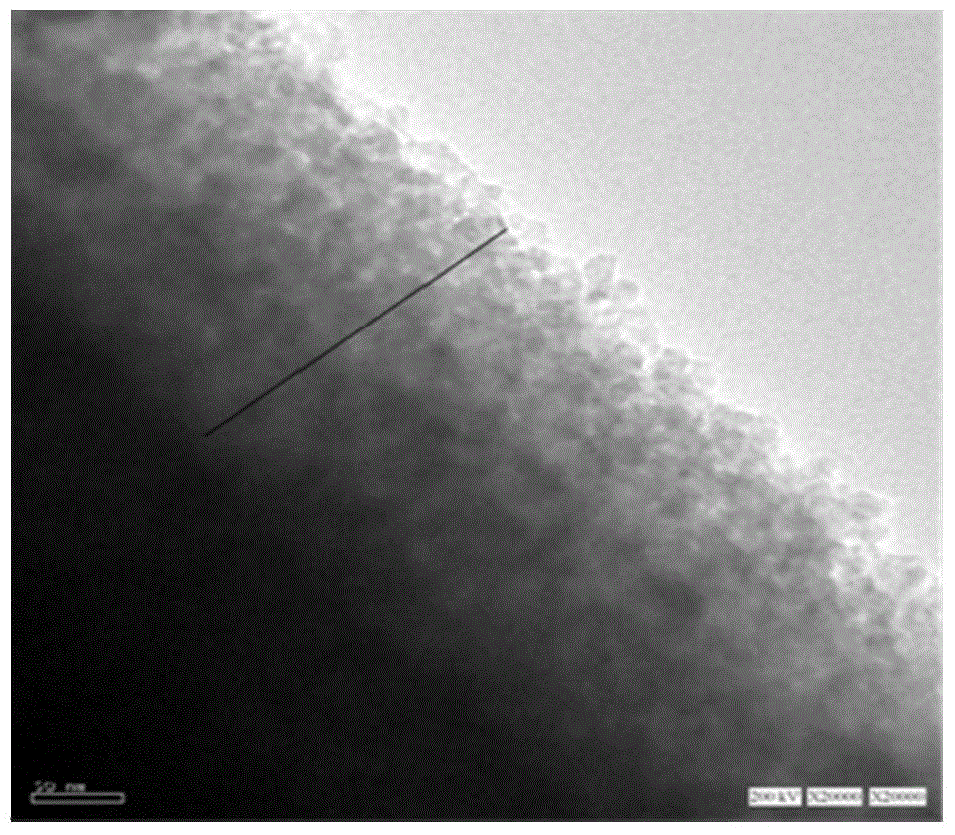

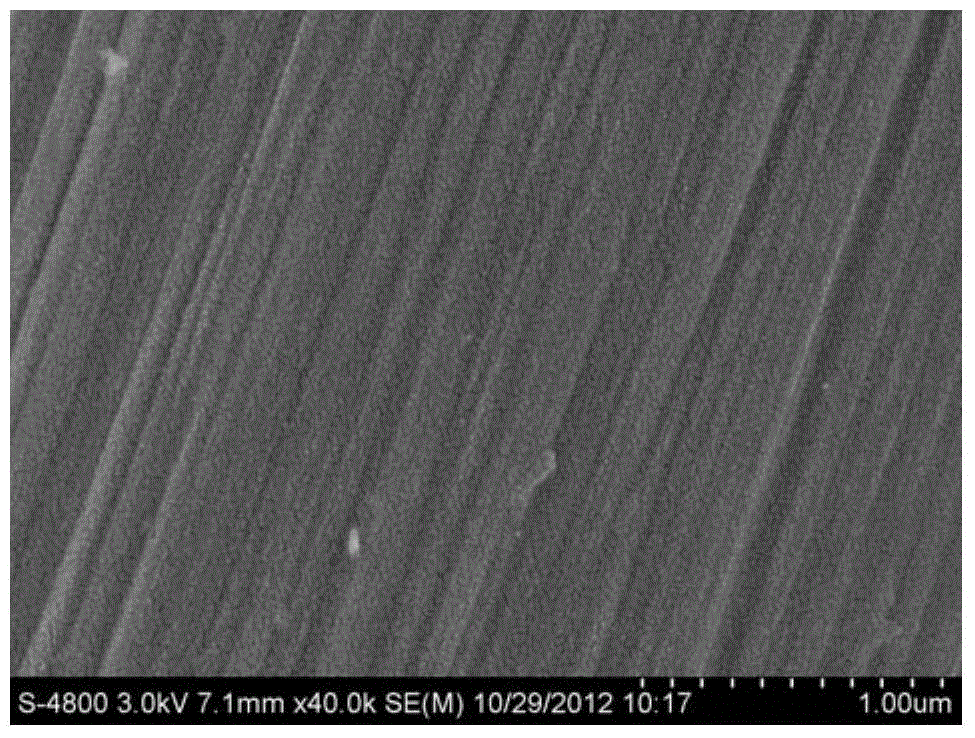

[0026] (2) Prepare aluminum sol by sol-gel method (viscosity is 0.012Pa.s, sol concentration is 1.2mol / L), soak the pretreated carbon fiber for 6h, take out, remove excess sol, dry at 100°C for 2h, repeat dipping and drying for 3 Second, calcined at 600 °C for 3 h under high-purity argon atmosphere; the transmission diagram of the modified catalyst support is shown in figure 1 As shown, the surface of the carbon fiber is coated with a 150nm alumina coating; and then roasted at 350°C for 2 hours in an atmosphere with an oxygen content of 0.5%, to obtain a carrier-modified carbon fiber. The scanning electron microsc...

Embodiment 2

[0028] Embodiment 2 A kind of preparation method of acetylene selective hydrogenation ethylene catalyst

[0029] Proceed as follows:

[0030] (1) Get 12g of pitch-based carbon fiber (fiber diameter 5 μm), and remove the surface coating by gas phase oxidation to obtain pretreated carbon fiber, which is set aside;

[0031] (2) Prepare silica sol (viscosity 0.010 Pa.s, sol concentration 1mol / L) by sol-gel method, soak carbon fiber for 2 hours, take out, remove excess sol, dry at 80°C for 4 hours, repeat dipping and drying twice, high Calcined at 550°C for 3h under pure argon atmosphere. Calcined at 550°C for 1 hour in an atmosphere with a water vapor content of 0.5%, to obtain carrier-modified carbon fibers;

[0032] (3) The active component precursor Pd and the co-catalyst precursor Ag were loaded on the modified carbon fiber by impregnation method, dried at 80 °C for 6 h, and roasted at 750 °C for 2 h under the protection of high-purity argon. The loading amount of Pd was 1% ...

Embodiment 3

[0033] Embodiment 3 A kind of preparation method of acetylene selective hydrogenation ethylene catalyst

[0034] Proceed as follows:

[0035] (1) Take 8 g of PAN-based carbon fiber filaments (fiber diameter 0.5 μm), remove the glue in a resistance furnace, and obtain pretreated carbon fibers for future use;

[0036] (2) Prepare titanium sol by sol-gel method (viscosity is 0.065Pa.s, sol concentration is 1.5mol / L), soak carbon fiber for 2h, take it out, remove excess sol, dry at 60°C for 4h, repeat dipping and drying for 4 times , calcined at 550°C for 4h in a high-purity argon atmosphere, and calcined at 450°C for 1.5h in an atmosphere with an oxygen content of 6%, to obtain carrier-modified carbon fibers;

[0037] (3) Load the active component precursor Pd and the co-catalyst precursor K and La on the modified carbon fiber by impregnation method, dry at 60°C for 4h, and bake at 550°C for 2h under the protection of high-purity argon. 0.6%, the K loading is 3% of the mass of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com