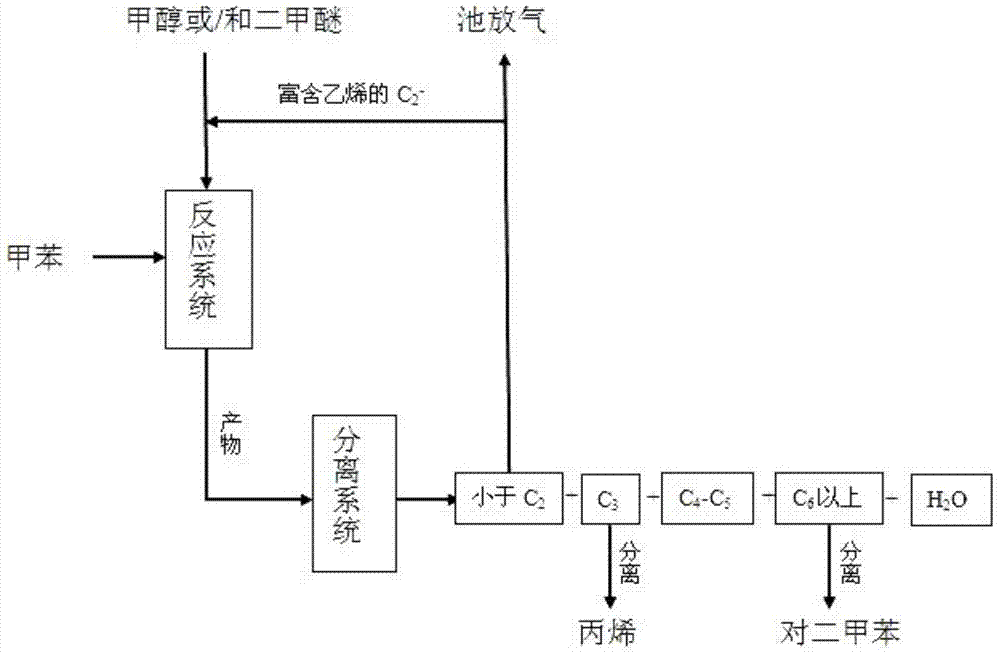

Method for preparing paraxylene and propylene

A technology for p-xylene and propylene, which is applied in the field of high-selectivity preparation of p-xylene and propylene, can solve problems affecting economy, large investment and energy consumption, and achieve the effect of improving economy and avoiding high costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1 (catalyst 1 preparation)

[0045] 500g ZSM-5 zeolite molecular sieve raw powder (SiO 2 / Al 2 o 3 =68) (Catalyst Factory of Fushun Petrochemical Company) Roasted at 550°C to remove template agent, exchanged 4 times with 0.5 molar equivalent ammonium nitrate solution in 80°C water bath, dried solid samples in air at 120°C Calcined in air for 4 hours to obtain HZSM-5 zeolite molecular sieve.

[0046] Modification of HZSM-5 zeolite molecular sieve by hydrothermal treatment: Take 200g of HZSM-5 molecular sieve and place it in a quartz reactor, heat it up to 650°C and then feed water with a water flow rate of 5ml / min, and treat it at a constant temperature for 4 hours to obtain a hydrothermal modification. Sexual HZSM-5 zeolite molecular sieve. Surface modification of hydrothermally modified HZSM-5 zeolite molecular sieves was carried out using siloxane reagent tetraethyl silicate. The steps are: immerse the hydrothermally modified HZSM-5 zeolite molecular s...

Embodiment 2

[0047] Embodiment 2 (catalyst II preparation)

[0048] (1) 500g ZSM-5 zeolite molecular sieve raw powder (SiO 2 / Al 2 o 3 =38) (Nankai University Catalyst Factory) roasted at 550°C to remove the template agent, exchanged 4 times with 0.5 molar equivalent ammonium nitrate solution in a water bath at 80°C, dried the solid sample in air at 120°C after exchange, and dried it at 550°C Calcined for 4 hours to obtain HZSM-5 zeolite molecular sieve.

[0049] (2) Take 200g of the HZSM-5 zeolite molecular sieve prepared in step (1), and use 8% mass concentration of zinc nitrate [Zn(NO 3 ) 2 ·6H 2 O] soaked in the solution at room temperature for 4 hours, poured out the upper liquid, dried the solid sample in air at 120°C, and roasted in air at 550°C for 6 hours to obtain zinc-modified Zn-HZSM-5 zeolite molecular sieve. Elemental analysis shows that the Zn content is 2.45wt%.

[0050] (3) Use orthoethyl silicate (TEOS) to impregnate the Zn-HZSM-5 zeolite molecular sieve obtained i...

Embodiment 3

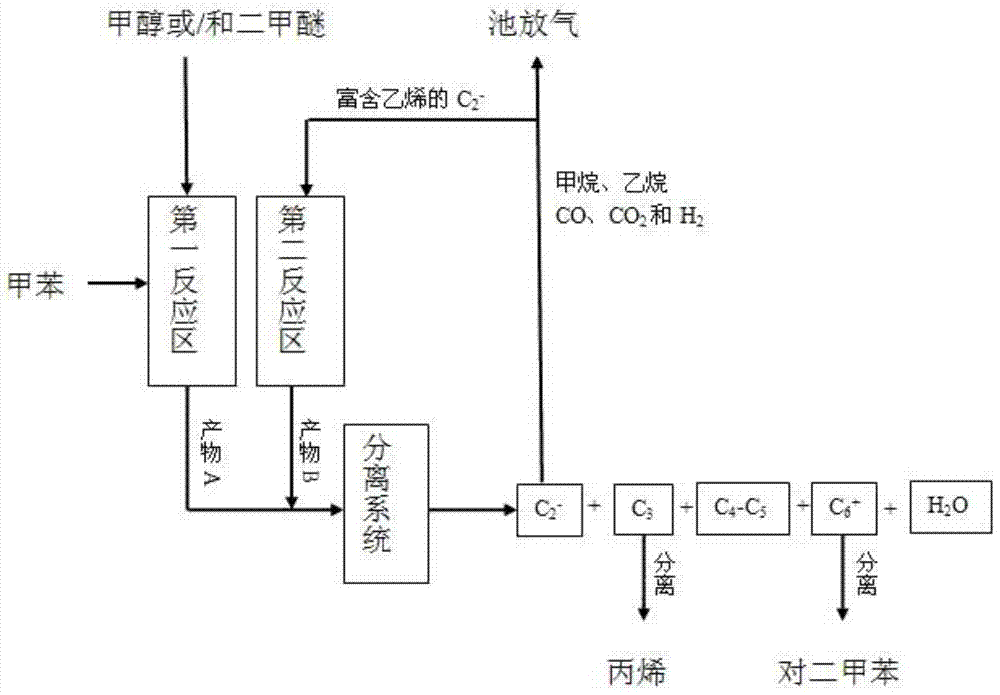

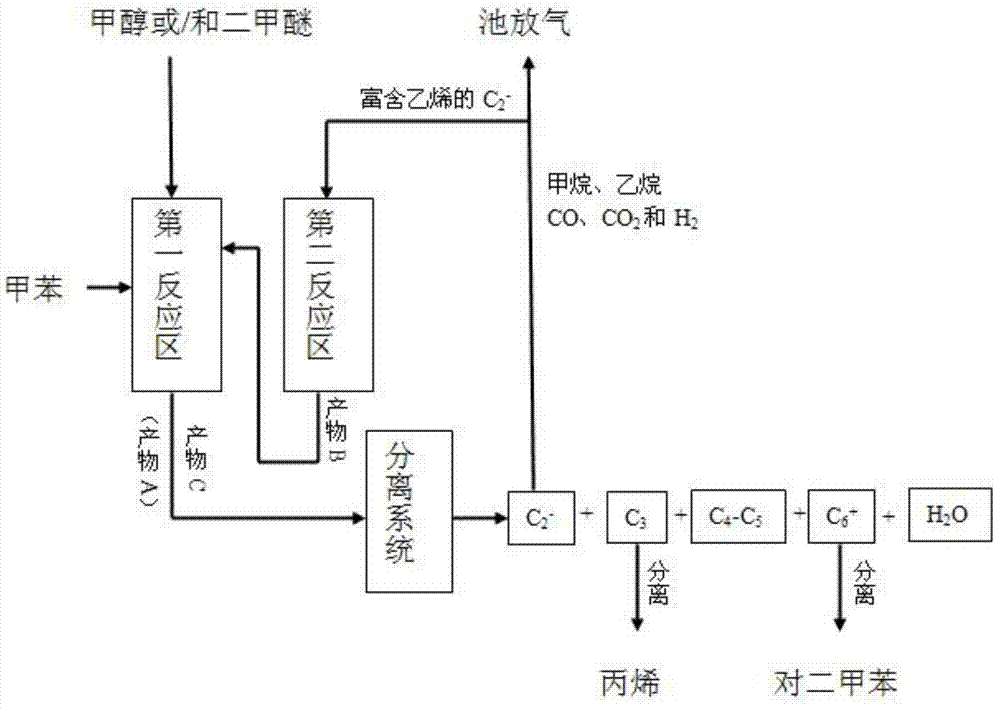

[0058] Example 3 ( figure 2 reaction system shown)

[0059] The TMPC-01 prepared in Example 1 and the TMPC-02 catalyst prepared in Example 2 were pressed into tablets respectively and crushed and sieved into 40-60 purpose catalyst samples, and each 10 grams of catalyst was loaded into the two sides of the fixed bed reactor. a reaction zone. The first reaction zone carries out the conversion reaction of toluene and methanol, and the second reaction zone carries out the ethylene aromatization reaction. 2 - The composition of components prepares ethylene-rich raw materials and enters the second reaction zone for aromatization.

[0060] Reaction conditions: The mass space velocity of toluene in the first reaction zone is 2h -1 , the reaction temperature is 480°C; the reaction temperature in the second reaction zone is 450°C. Gas chromatography was used to analyze the composition of the mixed product in the reaction zone online, and the distribution of hydrocarbon products af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com