Multifunctional thermal insulation coating containing titanium dioxide/attapulgite nanocomposite material and preparation method thereof

A nano-composite material, titanium dioxide technology, applied in the field of coatings, can solve the problems that affect the uniformity of coatings and related properties, and the easy sedimentation of inorganic additives, etc., to achieve excellent ultraviolet light shielding performance, improve heat insulation performance, and high surface energy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

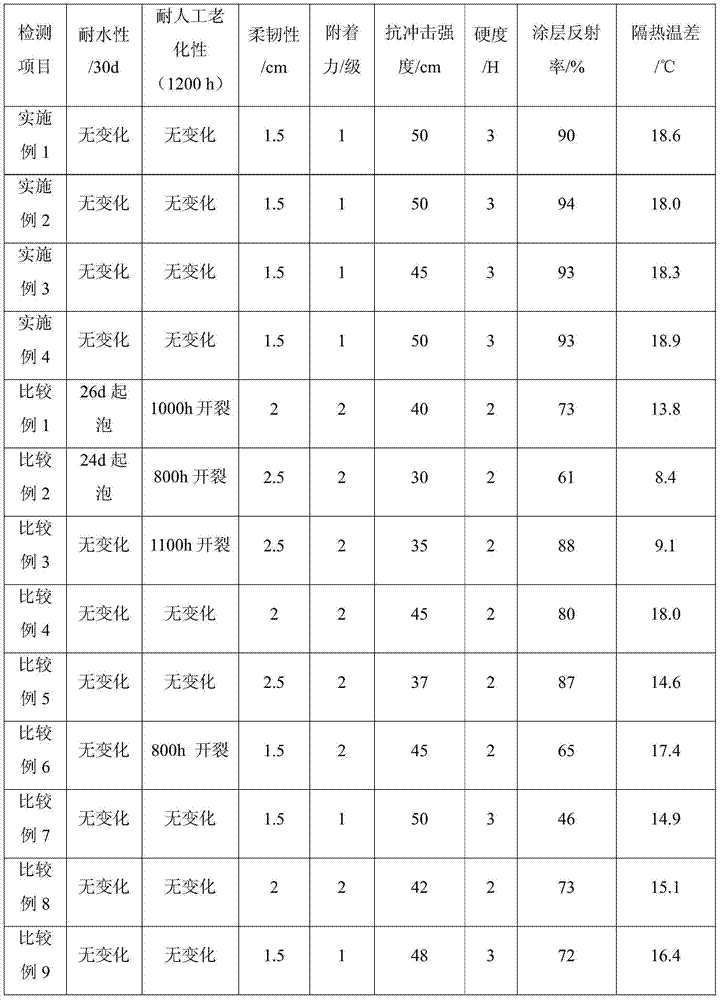

Examples

Embodiment 1

[0032] (1) Disperse 5g titanium dioxide / attapulgite nanocomposite in 100g water-ethanol solution, the volume ratio of water and ethanol is 1:2, add 0.3g silane coupling agent vinyltrimethoxysilane, 0.6g pentene Diacid, heat preservation reaction at 40° C. for 3 hours, filter, wash, and dry to prepare an organically modified titanium dioxide / attapulgite nanocomposite material.

[0033] (2) Preparation of modified styrene-acrylic emulsion: get organically modified titanium dioxide / attapulgite nanocomposite material 5g, styrene 15g, acrylic acid 2g, butyl acrylate 20g, methacrylic acid 1g, formazan 1 g methyl acrylate, emulsifier OP-101 g, protective gel sodium polymethacrylate 1.5 g, buffering agent baking soda 0.3 g, and deionized water 60 g were emulsified under vigorous stirring to obtain an emulsion. Take 30% of the above emulsion, add 30% initiator potassium persulfate, heat up to 70°C, keep warm for 2 hours, add the remaining emulsion and initiator, the total amount of ini...

Embodiment 2

[0036] (1) Disperse 10g titanium dioxide / attapulgite nanocomposite in 100g water-ethanol solution, the volume ratio of water and ethanol is 1:6, add 0.45g silane coupling agent vinylmethyldimethoxysilane, 0.6g Butenedioic acid was incubated at 80° C. for 1 hour, filtered, washed, and dried to obtain an organically modified titanium dioxide / attapulgite nanocomposite material.

[0037](2) Preparation of modified styrene-acrylic emulsion: get organically modified titanium dioxide / attapulgite nanocomposite material 10g, styrene 25g, acrylic acid 1g, butyl acrylate 25g, methacrylic acid 2g, formazan Methyl acrylate 4g, emulsifier K123g, protective gel sodium polyacrylate 1g, buffer disodium hydrogen phosphate 0.2g, deionized water 50g, and emulsify under vigorous stirring to obtain an emulsion. Take 40% of the above emulsion, add 50% initiator, heat up to 60°C, keep warm for 1.5h, add the remaining emulsion and initiator, the total amount of initiator ammonium persulfate is 0.3g, h...

Embodiment 3

[0040] (1) Disperse 15g titanium dioxide / attapulgite nanocomposite in 100g water-ethanol solution, the volume ratio of water and ethanol is 1:4, add 0.45g silane coupling agent vinyltrimethoxysilane, 1.2g butene Diacid, heat preservation reaction at 60° C. for 2 hours, filter, wash, and dry to prepare an organically modified titanium dioxide / attapulgite nanocomposite material.

[0041] (2) Preparation of modified styrene-acrylic emulsion: get organically modified titanium dioxide / attapulgite nanocomposite material 1g, styrene 20g, acrylic acid 0.5g, butyl acrylate 15g, methacrylic acid 0.5g obtained in step (1) , methyl methacrylate 2g, emulsifier MS-1 2g, protective glue polystyrene-maleic anhydride copolymer sodium salt 2g, buffer agent baking soda 0.25g, deionized water 40g, emulsify under vigorous stirring, Prepare an emulsion. Take 20% of the above emulsion, add 40% initiator, heat up to 80°C, keep warm for 1h, add the remaining emulsion and initiator, the total amount o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com