A preparing method of a nickel cobalt lithium aluminate cathode material

A technology of lithium nickel cobalt aluminate and positive electrode materials, which is applied to battery electrodes, electrical components, electrochemical generators, etc., can solve problems such as difficult and uniform co-precipitation at the same time, achieve easy industrial production, simplify production difficulty, and solve poor uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

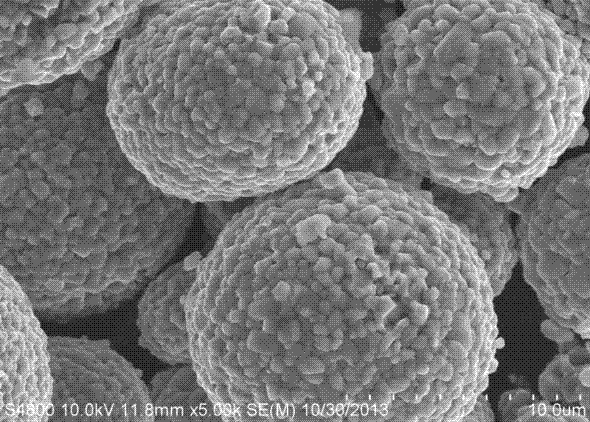

[0036] Mixed salt solution of nickel sulfate and cobalt sulfate, ammonia water and sodium hydroxide solution with a metal molar ratio of 85:15 were added to the reaction kettle at the same time through a metering pump, stirred at 80°C to form a precipitate, and the overflowed slurry was fully washed and washed. Filter and dry to obtain a filter cake and make nickel-cobalt compound dry powder.

[0037] The above dry powder, D 50 6um lithium carbonate, D 50 A 40nm aluminum oxide suspension was added simultaneously at a molar ratio of 1.00:1.00:0.10 for mixing and stirring, and was stirred and heated at 60°C. The dried material was sintered at 1000° C. for 10 h in a dry oxygen atmosphere. After sintering, the material is crushed to obtain the final product.

Embodiment 2

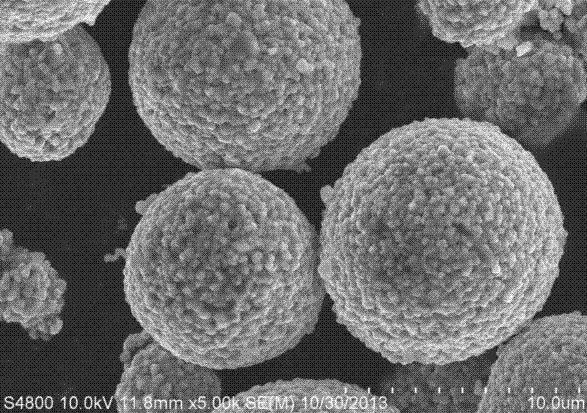

[0039] Mixed salt solution of nickel sulfate and cobalt chloride with a metal molar ratio of 80:20, ammonia water, and sodium carbonate solution are added to the reaction kettle at the same time through a metering pump, heated and stirred at 70°C to form a precipitate, and the overflowed slurry is fully washed and filtered, dried to obtain a filter cake and made into nickel-cobalt compound dry powder.

[0040] Mix and stir the above dry powder and aluminum nitrate solution, then add D 50 Lithium hydroxide of 2.1um, finally forming a mixed slurry with a molar ratio of 1.00:0.06:1.1, stirring and heating at 80°C. The dried material was sintered at 750° C. for 12 hours in a dry oxygen atmosphere. After sintering, the material is crushed to obtain the final product.

Embodiment 3

[0042] Nickel nitrate, cobalt sulfate mixed salt solution, ammonium bicarbonate solution, and sodium carbonate solution with a metal molar ratio of 83:17 were added to the reaction kettle at the same time through a metering pump, stirred at 60°C to form a precipitate, and the overflowed slurry was fully washed and filtered, dried to obtain a filter cake and made into nickel-cobalt compound dry powder.

[0043] The above dry powder, D 50 Stir 10um lithium hydroxide with appropriate amount of water, then add D 50 Alumina suspension of 50nm, finally forming a mixed slurry with a molar ratio of 1.00:1.10:0.06, stirring and heating at 70°C. The dried material was sintered at 900°C for 20h in a dry oxygen atmosphere. After sintering, the material is crushed to obtain the final product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com