Sludge treatment method for sewage plants

A treatment method and technology for sewage treatment, applied in sludge treatment, sludge treatment, biological sludge treatment, etc., can solve the problems of high heavy metal content in sludge, high moisture content of sludge, unstable properties, etc. Long life, good treatment effect, low noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

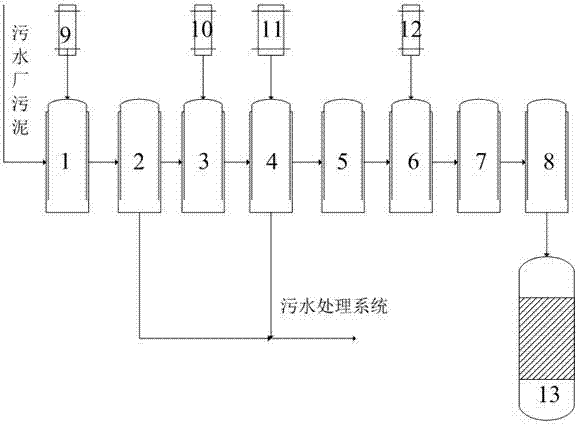

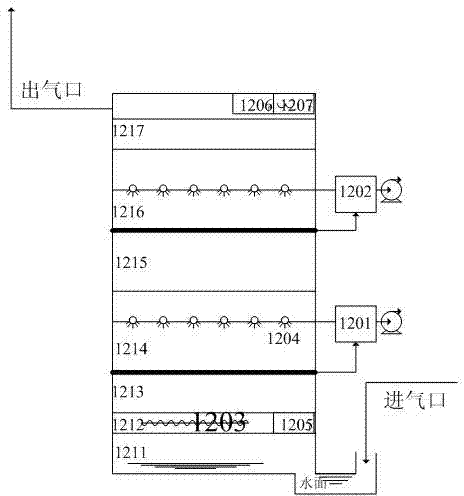

[0018] A method for treating sludge from a sewage plant. The sludge used in the sewage treatment process enters the sludge inlet of the sludge screen equipment 1 through a pipeline. The sludge screen equipment 1 is equipped with a 5-layer 18-mesh screen, and the screen is made of nylon material to separate the sludge. The bulky debris in the mud is screened out, and the debris collected in the sludge screening equipment is discharged into the waste tank through the pipeline, and then the sludge is discharged from the sludge outlet of the sludge screening equipment into the sludge thickening tank 2, and the sludge is concentrated Pool 2 is a circular vertical flow type, with a built-in mud scraper, liquid level gauge, sludge thickener and submersible mixer, an external sludge discharge pump, a sludge bucket at the bottom, and a supernatant drain on the pool wall. The dehydrated and concentrated sludge is discharged into the sludge inlet of the microwave digestion tank 3 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com