Method for preparing folic acid functional nanofibers for target capture of cancer cells

A nanofiber, targeted capture technology, applied in the direction of fiber type, fiber processing, conjugated synthetic polymer rayon, etc., can solve the problems of complex operation, high cost, cumbersome steps, etc., and achieve the effect of improving the capture ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

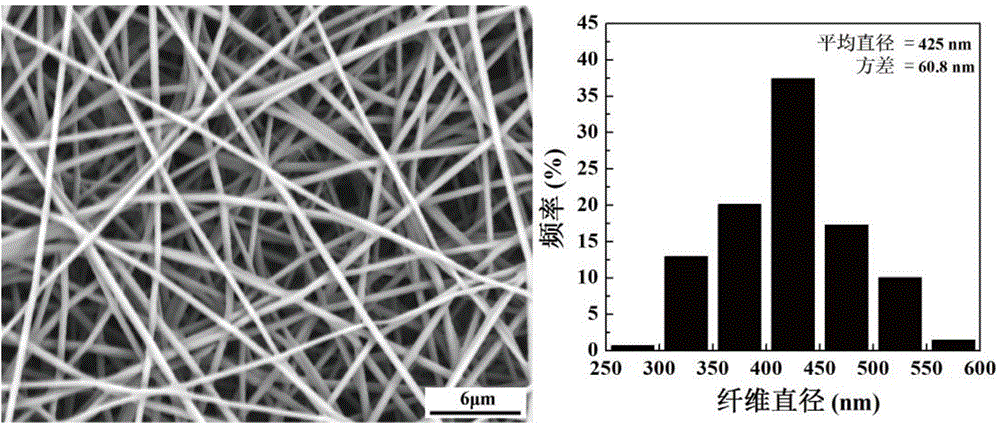

[0066] Prepare a 12wt% PVA solution with water as a solvent, and at the same time stir slowly with a glass rod for about 30 minutes until the PVA powder is completely swollen. Then, put a rotor in the beaker, place it on a magnetic stirrer, heat and stir in an 80°C water bath for 3 hours, and let it stand to cool. Then, PEI was added at a mass ratio of PVA:PEI=3:1, water was used as a solvent, dissolved by ultrasonic vibration and magnetically stirred overnight to make it uniformly dispersed, and configured as a PVA / PEI blended solution. Electrospinning experiments were carried out at room temperature and humidity less than 50%. The electrospinning device consists of a high-voltage power supply (which can provide a DC voltage of 0-40 kV), a syringe pump, a syringe, a stainless steel needle with an inner diameter of 1.0 mm, and a grounded collecting aluminum plate. The technological parameters in the spinning process are set as follows: the voltage is 18.6kv, the flow rate is ...

Embodiment 2

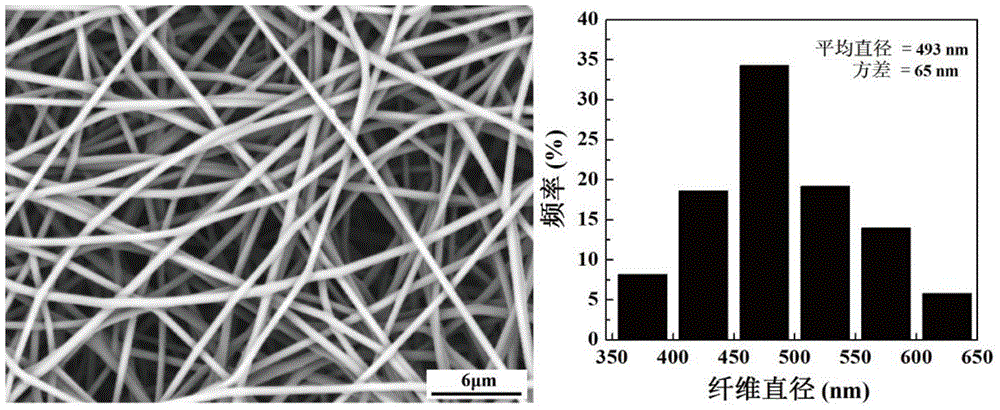

[0068] Adopt glutaraldehyde vapor crosslinking method to carry out crosslinking treatment to the PVI / PEI nanofiber that implements 1 to obtain, and its specific operation process is, the fiber membrane is covered on the petri dish that fills 20ml 25% glutaraldehyde solution, two Put them together in a desiccator, vacuum cross-linking for 18h. Rinse the cross-linked fiber membrane in water, and then take it off. At this time, it can be found that the fiber membrane is insoluble in water, that is, the modification treatment is completed. Then wash it with deionized water for 3-5 times, and put it into a vacuum drying oven for 12-24h. SEM results showed that after cross-linking with glutaraldehyde vapor, the fiber morphology was still good, and the average diameter of the cross-linked nanofibers was 493nm, which was 70nm different from the average diameter of 425nm of the PVA / PEI nanofibers without hydrophobic treatment. Left and right, it shows that on the glutaraldehyde cross-...

Embodiment 3

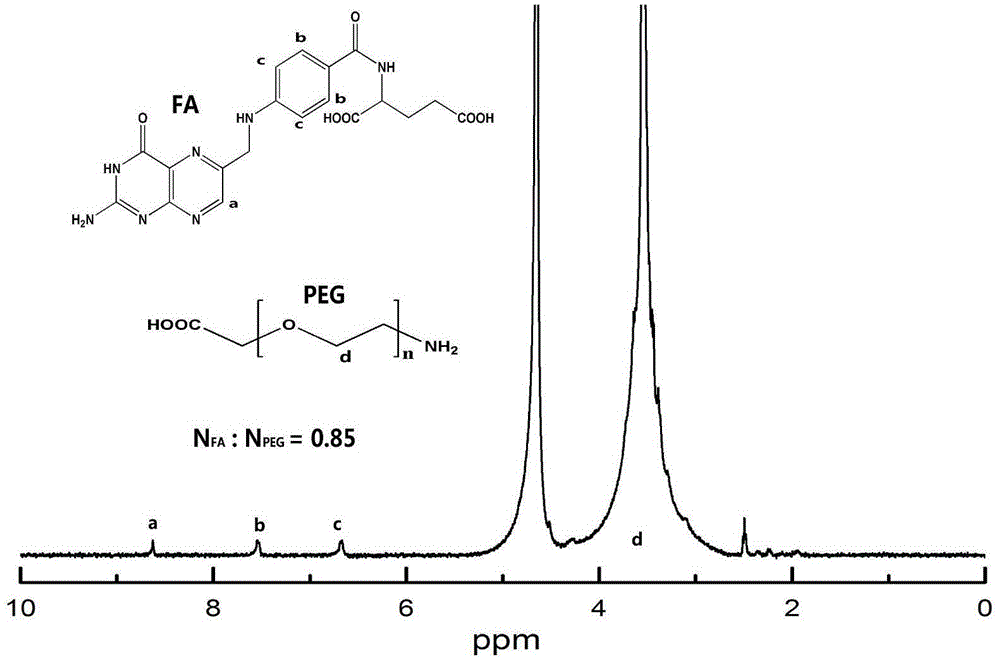

[0070] Preparation of FA-PEG-COOH. Known NH 2 -M of PEG-COOH W The molecular weight of FA is 441.4; the molecular weight of EDC·HCl is 191.7; the molecular weight of NHS is 115.09. Weigh NH 2 - PEG-COOH 79.42 mg, dissolved in 5 ml of DMSO. Take FA:EDC·HCl:NHS:NH 2 - PEG-COOH molar ratio = 2.5:2:2:1 Calculate the required mass of FA to be 43.82mg, which is dissolved in 5ml DMSO. The required EDC·HCl and NHS were 15.22 mg and 9.14 mg, respectively, dissolved in 1 ml of DMSO. The carboxyl groups in FA were activated by EDC·HCl and NHS, and the reaction time was 3 h. FA after activation of the carboxyl group for 3 h, added to NH 2 -PEG-COOH, mixed on a magnetic stirrer for 3 days.

[0071] After the reaction, the reaction product was transferred to a dialysis bag with a molecular weight cut off of 1000, and dialyzed in distilled water for 3 days (6x2L). Then freeze-drying is carried out to obtain the FA-PEG-COOH reaction product. figure 1 shown 1 The H NMR spectrum indi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com