Kefir particle fermented ginseng powder

A technology of fermenting ginseng and 3%-15% kefir, applied in food science, plant raw materials, applications, etc., can solve the problems of ginsenoside loss, rare ginsenoside types and contents, and many by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The preparation of embodiment 1 Kefir grain fermented ginseng powder

[0021] Ginseng was purchased in Jilin City market; kefir grains were purchased in Changchun Market

[0022] 1. Steaming: Steam the whole fresh ginseng at 80-100°C for 20-30 minutes;

[0023] 2. Beating: use a multi-function cooking machine to process for 60-90s;

[0024] 3. Sterilization: use a high-pressure steam sterilizer at 110°C to 125°C for 10 to 15 minutes;

[0025] 4. Fermentation: add 3%-15% kefir grains (mass ratio) to ginseng raw materials and cultivate at 28°C-30°C for 36-60 hours to obtain fermentation broth;

[0026] 5. Freeze-drying: the fermented liquid is freeze-dried at -55°C to -65°C for 36-48 hours to obtain fermented ginseng powder.

Embodiment 2

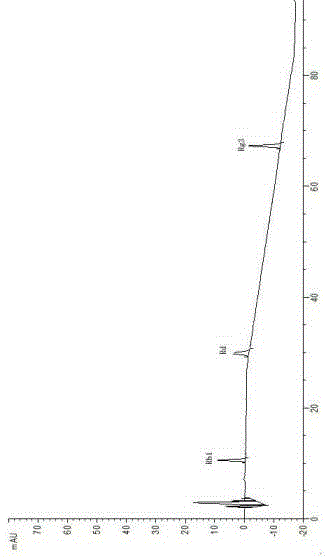

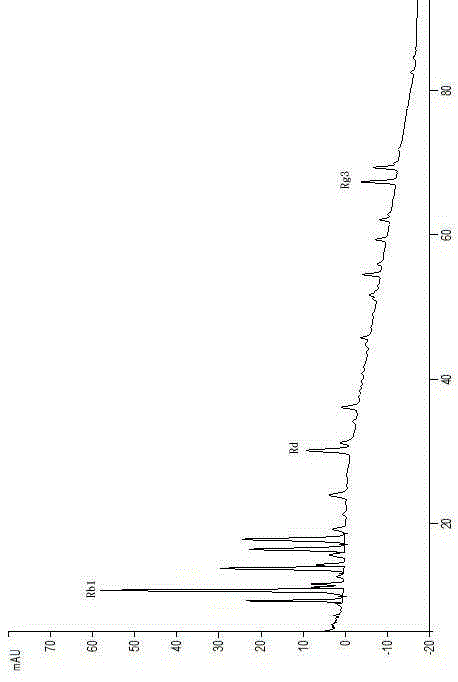

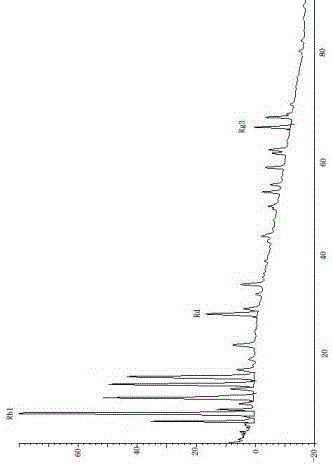

[0027] Ginsenoside determination of embodiment 2 Kefir grain fermented ginseng powder

[0028] 1. Preparation of Ginseng Standards

[0029] Accurately weigh 2 mg each of ginsenosides Rb1, Rg3, Rd, Rh2, RC, and Re, and add 100% methanol to 10 mL to obtain 0.2 mg / mL.

[0030] 2. Preparation of the test solution

[0031] Take 1 g of fermented ginseng powder prepared in Example 1 with a fermentation time of 48 hours and a temperature of 29°C, accurately weigh it, put it in a Soxhlet extractor, add chloroform and heat to reflux for 3 hours, discard the chloroform liquid, and evaporate the medicinal residues to dryness The solvent, together with the filter paper cylinder, was transferred into a 100mL Erlenmeyer flask, accurately added with 50mL of water-saturated n-butanol, sealed, left overnight, ultrasonically treated (power 250W, frequency 50Hz) for 30 minutes, filtered, and the filtrate was precisely weighed 25mL, placed in the evaporation Evaporate to dryness in a dish, add 1...

Embodiment 3

[0039] Example 3 Determination of basic nutritional characteristics of Kefir grain fermented ginseng powder

[0040] Ginseng dietary fiber is determined according to GB / T5009.88-2008; ginseng soluble protein is determined according to GB / T5009.5-2010, using the micro Kjeldahl method for determination; ginseng total protein is determined by Kjeldahl method; ginseng polysaccharide Phenol-sulfuric acid method was used for determination; data processing and statistics were performed by using Microsoft Excel 2007 for experimental data analysis; GeL gro software was used for TLC experimental data analysis; Graphpad Prism5 was used for drawing; Math tap was used to draw formulas.

[0041] The content changes of basic nutritional characteristics in ginseng test products are shown in Table 2 below

[0042]

[0043]From Table 2, we can see that the soluble dietary fiber, soluble protein, and total protein in the fermented ginseng test samples all increased to a certain extent.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com