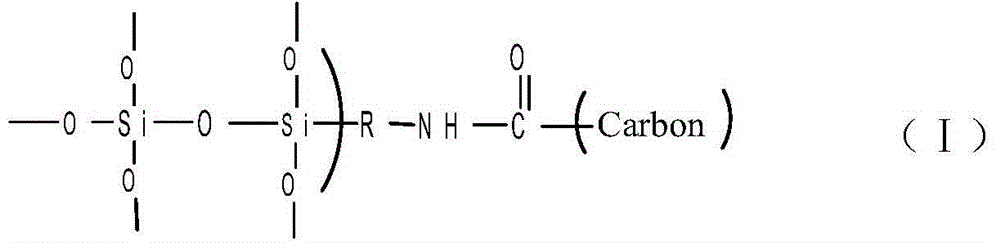

Modified carbon dioxide shaped phase change material and preparation method thereof

A phase-change energy storage material, silicon dioxide technology, applied in chemical instruments and methods, heat exchange materials, etc., can solve the problems of poor durability of materials, easy phase separation or precipitation, etc., and achieve good application value , Enhanced thermal conductivity, good dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

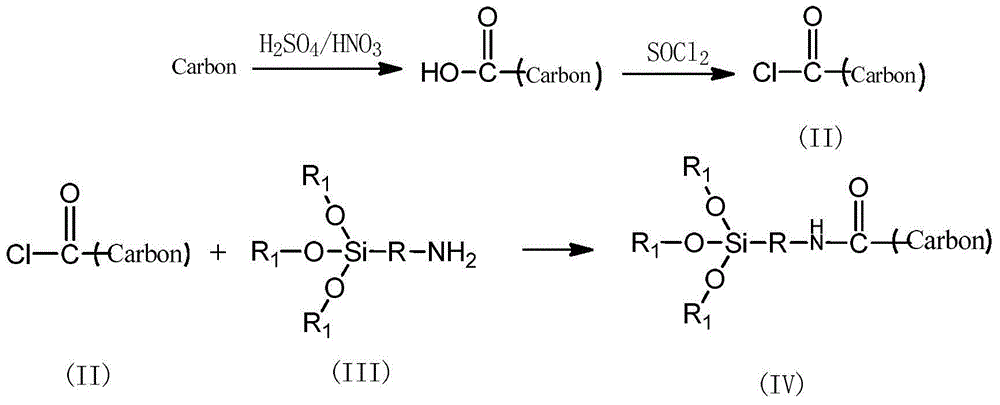

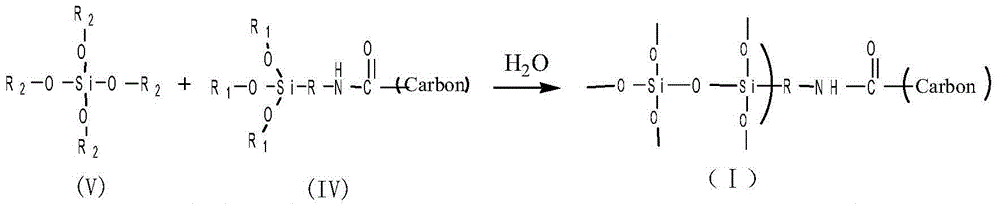

[0042] Example 1 Graphene-modified silica-coated n-octadecane phase-change energy storage material and its preparation

[0043] Mix 150mL of concentrated sulfuric acid and 50mL of concentrated nitric acid in proportion to make a mixed acid, add 5g of graphene into the mixed acid solution, then control the temperature at 100°C, react for 30min, stop heating, and wait for the reactant to cool to room temperature, then mix the mixture obtained from the above reaction Add deionized water to wash and filter repeatedly until the lotion is neutral, and the product obtained after drying is 4.9g, and 4.9g of the product is mixed with 50mL of SOCl containing 0.1gN,N-dimethylformamide 2 Mix, reflux at 80°C for 12 hours, centrifuge at 4000rmp, collect the precipitate, discard the liquid substance, wash the solid substance repeatedly with tetraoxyfuran to remove by-products, place it in a vacuum oven for 12 hours, and add to 200mL after drying Stir and disperse in toluene, add 10g of 3-ami...

Embodiment 2

[0048] Example 2 Carbon nanotube modified silica coated polyethylene glycol phase change energy storage material and its preparation

[0049] Mix 150mL of concentrated sulfuric acid and 50mL of concentrated nitric acid in proportion to make a mixed acid, add 5g of carbon nanotubes into the mixed acid solution, then control the temperature at 100°C, react for 30min, stop heating, and wait for the reactants to cool to room temperature Deionized water was added to the mixture to wash and filter repeatedly until the washing liquid was neutral, and 4.9 g of the product obtained after drying was mixed with 50 mL of SOCl containing 0.1 g N,N-dimethylformamide 2 Mix, reflux at 80°C for 12 hours, centrifuge at 4000rmp, collect the precipitate, discard the liquid substance, wash the solid substance repeatedly with tetraoxyfuran to remove by-products, place it in a vacuum oven for 12 hours, and add it to In 200mL of toluene, stir and disperse, add 10g of 3-aminopropyltriethoxysilane drop...

Embodiment 3

[0054] Example 3 Carbon nanotube modified silica coated palmitic acid phase change energy storage material and its preparation

[0055] Mix 150mL of concentrated sulfuric acid and 50mL of concentrated nitric acid in proportion to make a mixed acid, add 5g of carbon nanotubes into the mixed acid solution, then control the temperature at 100°C, react for 30min, stop heating, and wait for the reactants to cool to room temperature Deionized water was added to the mixture to wash and filter repeatedly until the washing liquid was neutral, and 4.9 g of the product obtained after drying was mixed with 50 mL of SOCl containing 0.1 g N,N-dimethylformamide 2 Mix, reflux at 80°C for 12 hours, centrifuge at 4000rmp, collect the precipitate, discard the liquid substance, wash the solid substance repeatedly with tetraoxyfuran to remove by-products, place it in a vacuum oven for drying for 12 hours, and add it to 200mL of toluene , stir and disperse, add 10g of 3-aminopropyltriethoxysilane d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase change enthalpy | aaaaa | aaaaa |

| Phase change enthalpy | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com