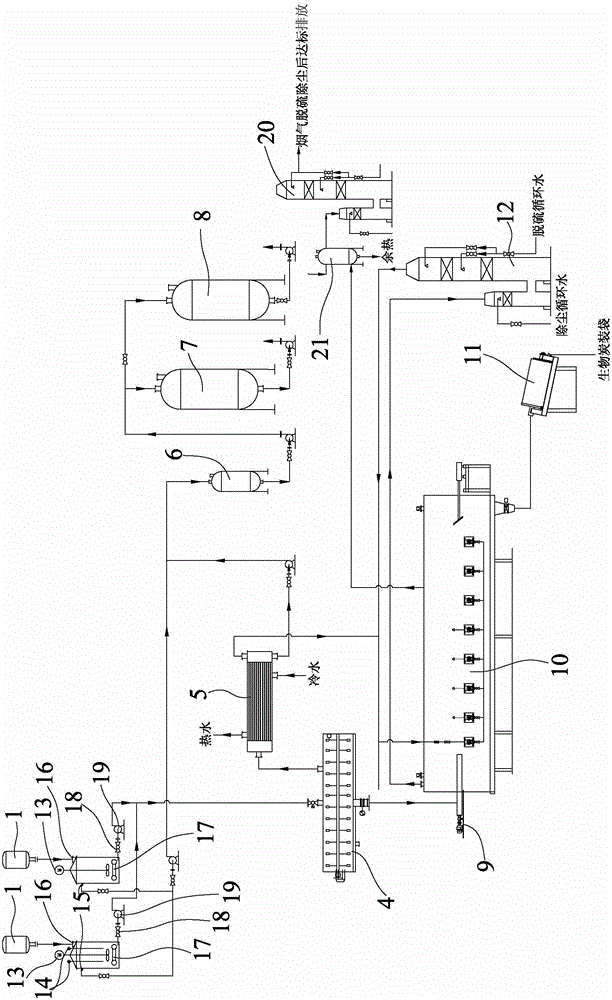

Deep recycling process and system for oily sludge

A technology for recycling and oil sludge, applied in the petroleum industry, sludge treatment, pyrolysis treatment of sludge, etc., can solve the problems of secondary pollution, incomplete disposal, high maintenance rate, and improve the dehydration rate and oil recovery. rate, realize resource utilization, and have the effect of broad prospects for utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

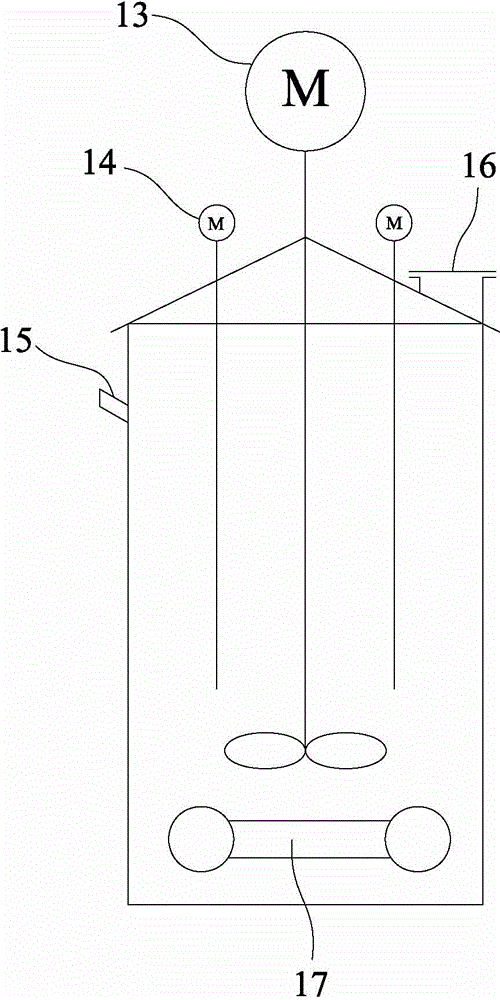

[0060] Floor sludge: oil content 14.5%, water content 19%, other solid content 66.5%. The processing capacity is 10m 3 (density 1.5t / m 3 ).

[0061] First, the 10 m 3 The ground sludge is sent from the storage yard to the conditioning tank. The temperature of the heating steam in the conditioning tank is 180 °C, and the temperature of the material in the tank is kept at 65 °C ~ 70 °C; the conditioning agent components are: demulsifier SP 2Kg, alum 4Kg, Cationic polyacrylamide 0.2Kg, clean water 1000Kg; put the conditioning agent into the conditioning tank, stir for 60 minutes, then start the vibrator for 30 minutes; after the vibration is completed, let the material stand for 60 minutes, start the water pump to extract conditioning The oil-water mixture in the upper part of the tank is 3850Kg, and the mixture is sent to the centrifugal separator for separation; the oily sludge in the lower part of the conditioning tank is pumped to the vacuum dehydrator for further drying, ...

example 2

[0063] Tank bottom sludge: oil content 53%, water content 25%, other solid content 22%. The processing capacity is 10m 3 (density 1.7t / m 3 ).

[0064] First, the 10 m 3 The oil sludge at the bottom of the tank is sent from the storage yard to the conditioning tank. The temperature of the heating steam in the conditioning tank is 180℃, and the temperature of the material in the tank is kept at 55℃~65℃; the conditioning agent components are: demulsifier SP 3Kg, alum 6Kg , cationic polyacrylamide 0.5Kg, clear water 2000Kg; put the conditioning agent into the conditioning tank, stir for 60 minutes, let it stand for 6 hours, start the water pump to extract the oil-water mixture in the upper part of the conditioning tank, and obtain a mixture of 8590Kg. The sludge is sent to the centrifugal separator for separation; the sludge in the lower part of the conditioning tank is pumped to the vacuum dehydrator for further drying, and the dehydrator feeds 5 m per batch. 3 , each feeding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com