A kind of preparation method of low resistivity isotropic graphite

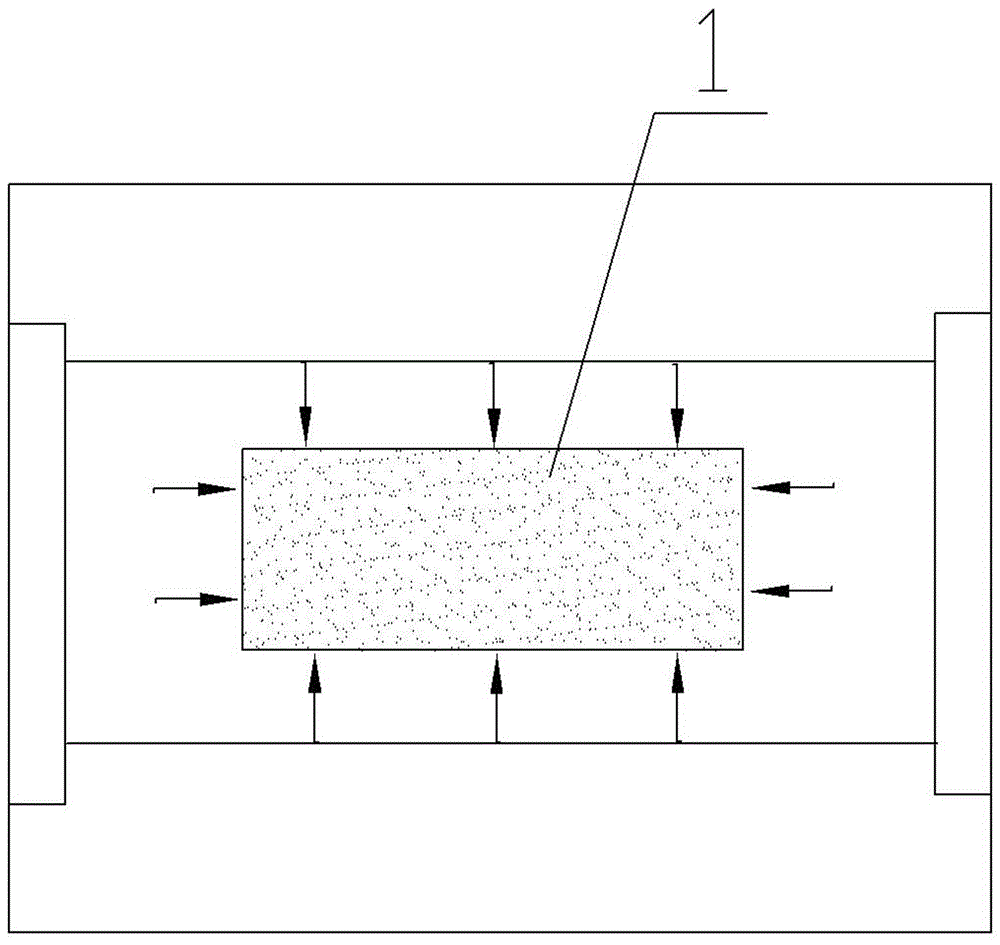

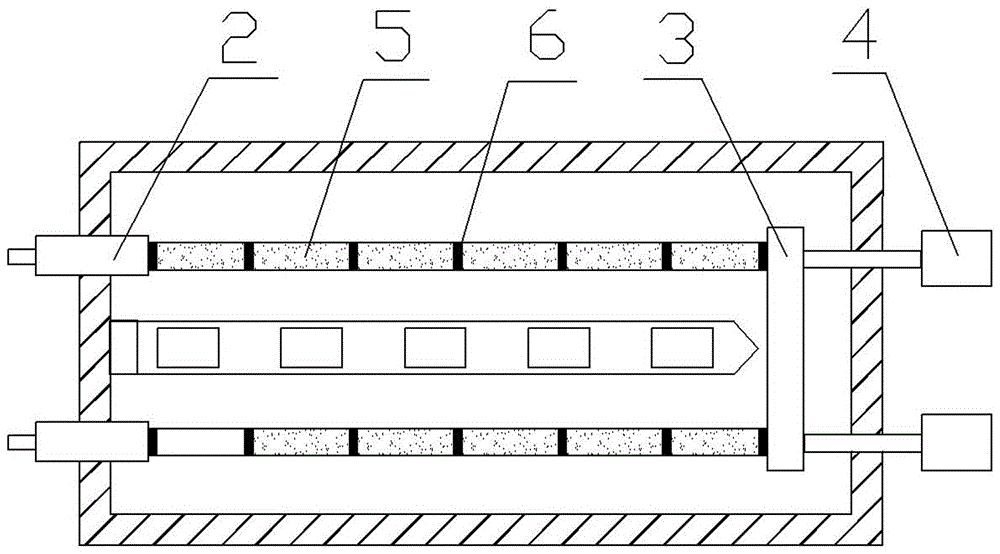

An isotropic and graphite technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of long roasting time, only 75% pass rate, high energy consumption, etc., and achieve fast heating speed and heat transfer And the effect of uniform heating and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The preparation process of the low-resistivity isotropic graphite green body of the present invention comprises the following steps:

[0044] ① material preparation

[0045] Requirements for raw materials used in the present invention: high-purity graphite powder requires a carbon content of 99.9%, an ash content of less than 300ppm, and a D50 of 15-25μm. The volatile matter of petroleum coke is less than 0.5%, the moisture is less than 0.5%, the ash content is less than 0.5%, and the resistivity is less than 500µΩ•m. Pitch coke sulfur content is less than 0.5%, volatile matter is less than 0.5%, water content is less than 0.5%, ash content is less than 0.5%, resistivity is less than 550µΩ•m. Modified asphalt requires a high-temperature softening point temperature of 100~115°C, a volatile content of less than 45%, a moisture content of less than 1%, an ash content of less than 0.3%, and a content of quinoline insolubles of less than 8%. It is commercially available and...

Embodiment 2

[0064] Carry out the preparation of the low-resistivity isotropic graphite green body and the serial electric roasting according to the steps of Example 1, the difference is: step 2. get the ground raw material powder respectively according to the following mass percentage: 32% high-purity graphite powder, 20% petroleum coke, 30% pitch coke, 16% modified pitch, 2% surfactant; step ③ mix the carbon powder and heat to 150°C while vacuuming.

[0065] After testing the performance parameters of graphite green body: density 1.54g / cm 3 , the resistivity is 1000µΩ•m, and the isotropic coefficient is less than 1.05.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com