Thermoset fluororesin powder coating preparation method

A powder coating and fluororesin technology, applied in powder coatings, coatings and other directions, can solve the problems of difficult process temperature control, affecting powder color and performance, affecting production efficiency, etc., achieving simple process, good storage stability at room temperature, Good quality product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

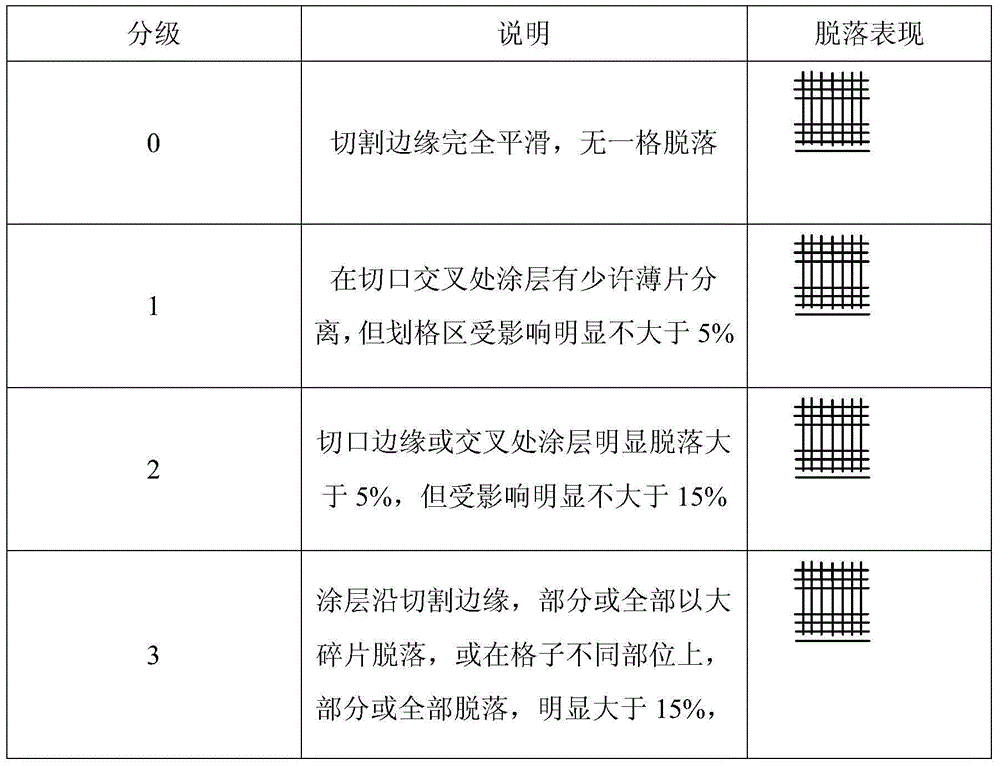

Method used

Image

Examples

Embodiment 1

[0033] (1) Through the cycle process of vacuuming and high-purity nitrogen replacement, deoxidize the high-pressure reactor to make the oxygen content in the reactor less than 23ppm. Then, by weight fraction, add 40 parts of methyl isoamyl ketone, 60 parts of trichlorotrifluoroethane, 7 parts of hydroxybutyl vinyl ether, 1 part of undecylenic acid, 33.9 parts of n-butyl vinyl ether, Veova9 single 12 parts of body, 1.1 parts of tert-butyl peroxy tert-butyl valerate, and the inside of the kettle was replaced twice with high-purity nitrogen again to remove residual oxygen in the solvent, and 35 parts of chlorotrifluoroethylene and 10 parts of tetrafluoroethylene were introduced. Stir, slowly raise the temperature to 78°C to start the polymerization reaction, end the reaction after 20 hours of polymerization reaction, then cool the reactor to 30°C with cooling water, recover the unreacted gas phase monomer and discharge the material, filter the feed liquid with diatomaceous earth, ...

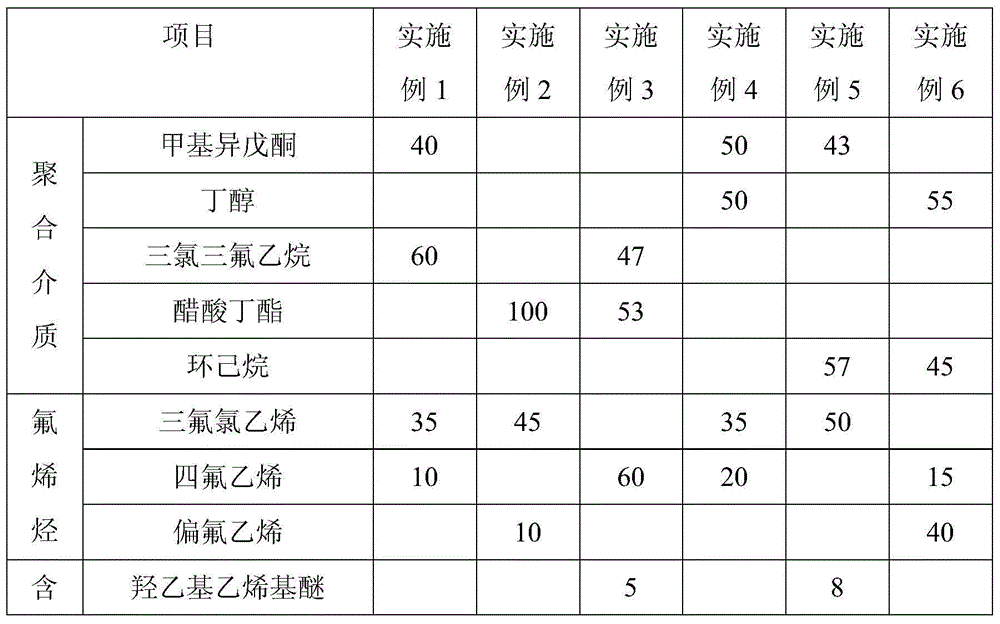

Embodiment 2~6

[0037] Using the same process as in Example 1, see Table 3 for the specific formulation and process of step (1) thermosetting fluororesin, and see Table 4 for the specific formulation of step (2) thermosetting fluororesin coating composition dispersion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com