Preparation method of slump-retaining polycarboxylic acid type water-reducer

A polycarboxylic acid-based, slump-preserving technology, applied in the field of polycarboxylic acid-based water reducing agents, can solve the problem that the grafting rate of maleic anhydride grafted β-cyclodextrin macromonomer is not high and cannot be fundamentally solved. Concrete slump loss, the preparation process is not environmentally friendly and other problems, to achieve the effect of excellent and stable product performance, simple and convenient operation steps, and shortened reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

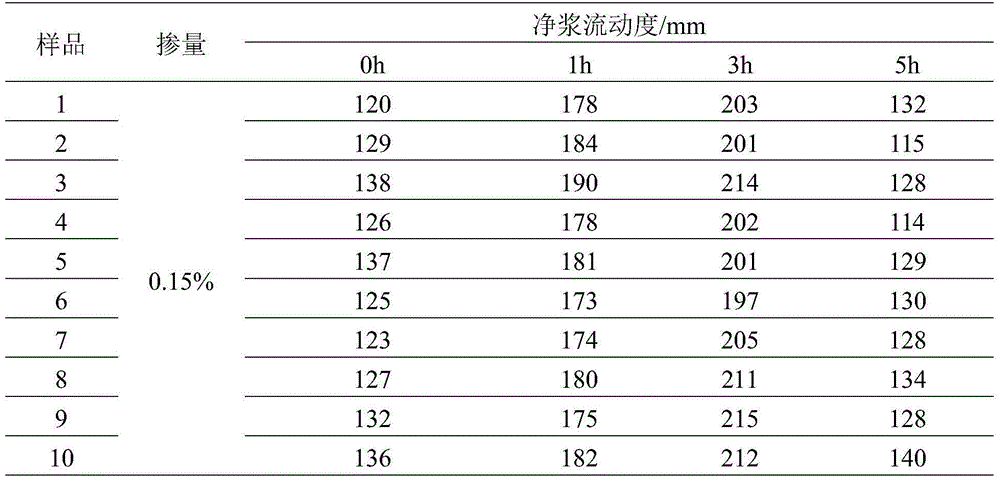

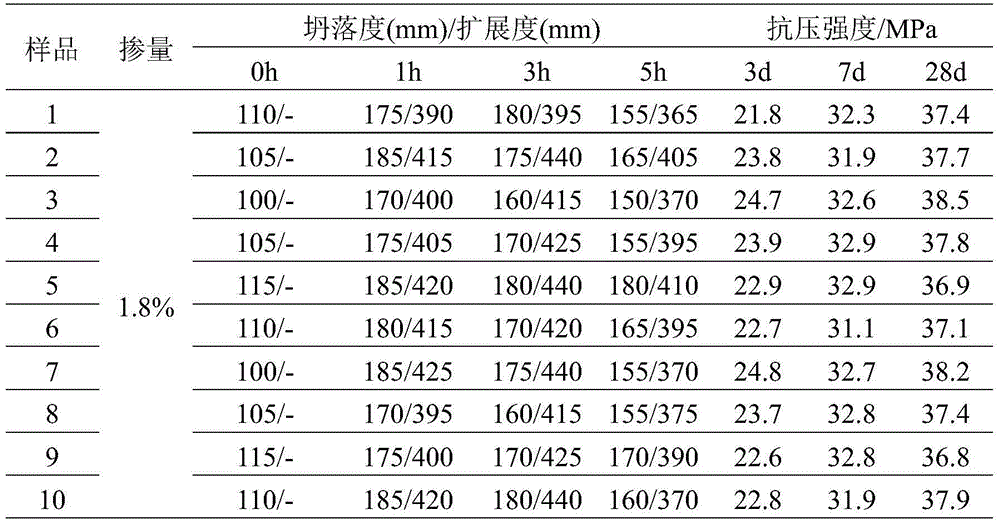

Examples

Embodiment 1

[0027] 1) Preparation of amine-containing copolymers: 10mol 2-methallyl alcohol and 10mol acrylamide at 25°C in 0.1mol tert-butyl hydroperoxide, 0.3mol Glycyrrhiza, 0.01mol sodium methallyl sulfonate Carrying out oxidation-reduction radical polymerization reaction 30min to obtain the copolymerization product that molecular weight is 3000;

[0028] 2) Preparation of epoxy-based polyethylene glycol monomethyl ether: add 10.1 mol of sodium hydride to 10 mol of polyethylene glycol monomethyl ether with a molecular weight of 5000 at 0°C, add 10.1 mol of epichlorohydrin for 40 minutes, and stir for 90 minutes Desalination obtains epoxy group polyethylene glycol monomethyl ether;

[0029] 3) Preparation of slump-preserving water reducer: add 10 mol of amine-containing copolymer to 10 mol of epoxy polyethylene glycol monomethyl ether for 10 minutes, add potassium hydroxide to neutralize and adjust the pH value to 6 to obtain a slump-preserving type Polycarboxylate superplasticizer. ...

Embodiment 2

[0031] 1) Preparation of amine-containing copolymers: 10 mol of allyl alcohol and 9 mol of allylamine were subjected to oxidation-reduction free radical polymerization under the action of 0.2 mol of tert-butyl hydroperoxide, 0.4 mol of sodium metabisulfite, and 0.02 mol of thioglycolic acid at 30°C for 35 minutes to obtain the molecular weight Be the copolymerization product of 3500;

[0032] 2) Preparation of epoxy-based polyethylene glycol monomethyl ether: Add 10.2 mol of sodium hydride to 10 mol of polyethylene glycol monomethyl ether with a molecular weight of 400 at 25°C, add 11 mol of epichlorohydrin for 10 minutes of reaction, stir for 90 minutes, and desalt to obtain Epoxy polyethylene glycol monomethyl ether;

[0033] 3) Preparation of slump-preserving water reducer: add 10 mol of amine-containing copolymer to 5 mol of epoxy polyethylene glycol monomethyl ether for 50 minutes, add calcium hydroxide to neutralize and adjust the pH value to 7 to obtain a slump-preservi...

Embodiment 3

[0035] 1) Preparation of amine-containing copolymers: 10mol hydroxymethyl acrylate and 8mol methacrylamide at 35°C in 0.3mol benzoyl peroxide, 0.6mol N,N-dimethylaniline, 0.03mol 2-mercaptopropionic acid Carrying out oxidation-reduction radical polymerization reaction 40min to obtain the copolymerization product that molecular weight is 5000;

[0036] 2) Preparation of epoxy-based polyethylene glycol monomethyl ether: add 10.5 mol of sodium hydride to 10 mol of polyethylene glycol monomethyl ether with a molecular weight of 2000 at 20°C, add 10.2 mol of epichlorohydrin for 10 minutes of reaction, and desalt after stirring for 40 minutes Obtain epoxy group polyethylene glycol monomethyl ether;

[0037] 3) Preparation of slump-preserving water reducer: add 10 mol of amino group-containing copolymer to 9 mol of epoxy polyethylene glycol monomethyl ether for 10 minutes, add sodium hydroxide to neutralize and adjust the pH value to 6.5 to obtain a slump-preserving type Polycarboxy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com