Microemulsified cutting fluid

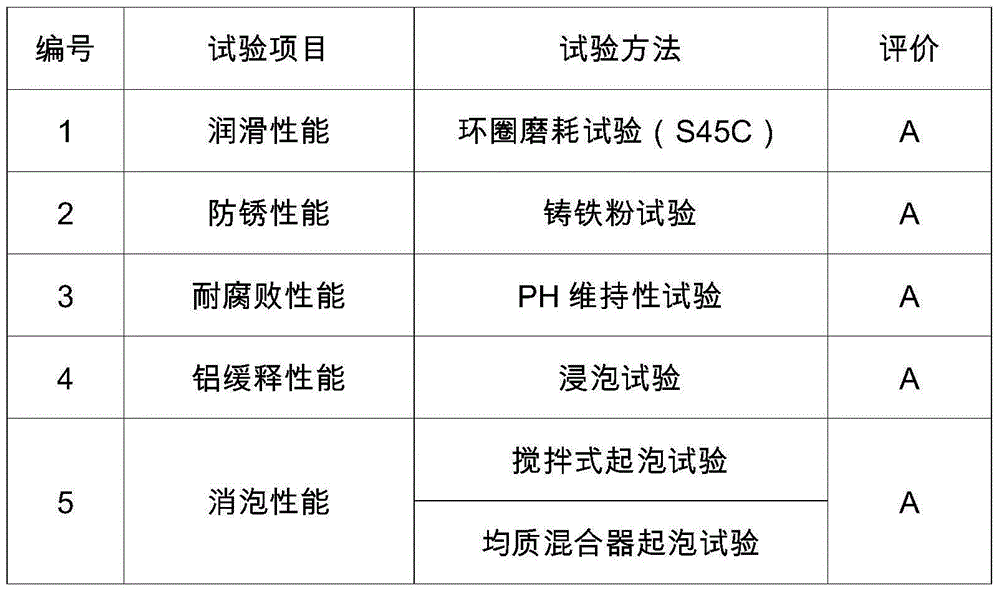

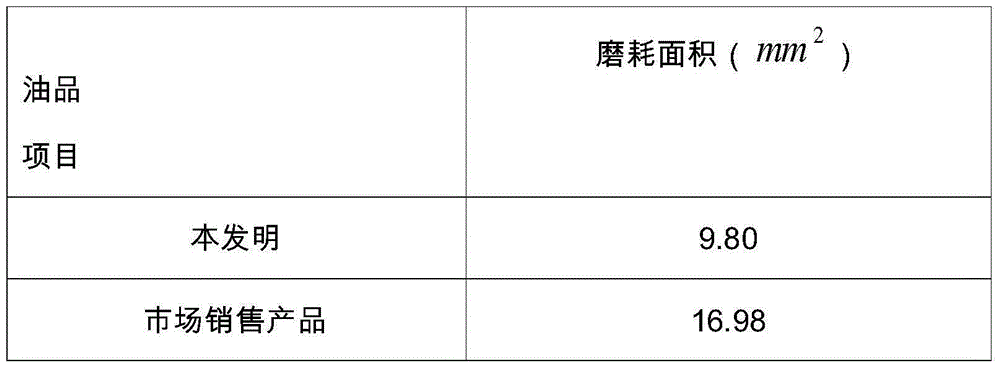

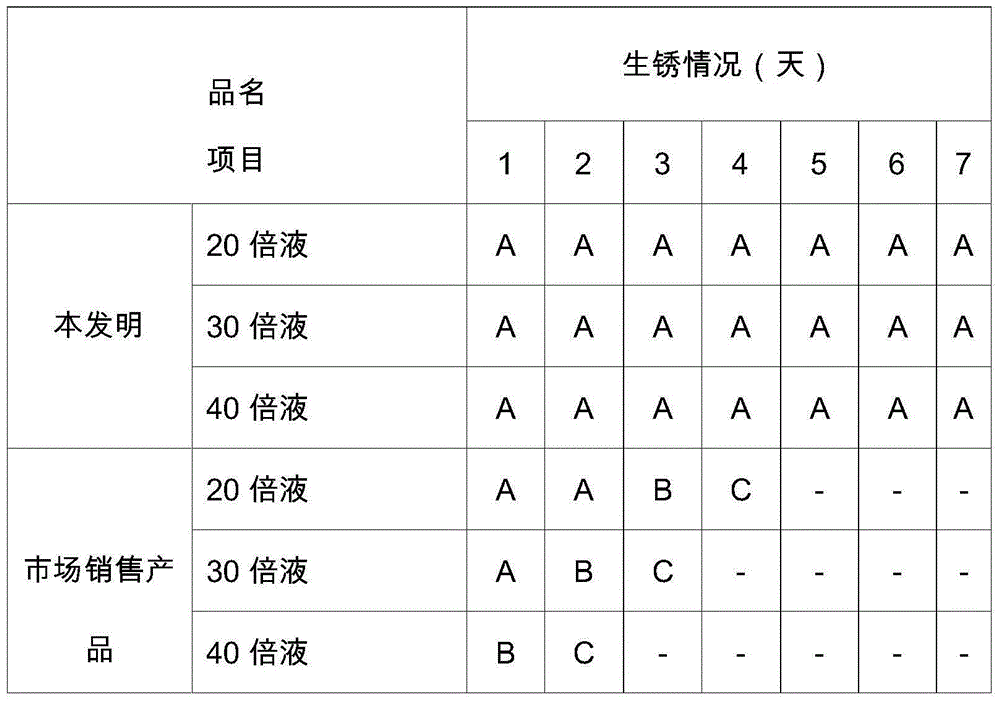

A cutting fluid, micro-emulsion technology, applied in the petroleum industry, lubricating compositions, etc., to achieve excellent rust resistance, good corrosion inhibition, and solve the effects of poor slow release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A kind of microemulsion cutting fluid described in this embodiment comprises the following components by weight:

[0039] PH value regulator: 20%, rust inhibitor: 0.5%, bacteriostatic agent: 0.5%, nonionic surfactant: 1.5%, anionic surfactant: 10%, corrosion inhibitor: 1%, base oil: 10% %, water: 43.5%.

Embodiment approach

[0041] Specifically, according to weight percentage, it includes the following components: triethanolamine: 20%; undecanedioic acid: 0.5%; molybdate: 0.5%; fatty alcohol polyoxyethylene ether: 1.5%; ricinoleic acid, Oleic Acid Mixture: 10%; Modified Phosphate: 1%; Naphthenic Mineral Oil: 10%; Water: 43.5%.

[0042] Specifically, according to weight percentage, it includes the following components: diethanolamine: 20%; sebacic acid: 0.5%; triazine derivatives: 0.5%; tall oil acid: 10%; polyoxyethylene sorbitan Fatty acid ester: 1.5%; Silicate: 1%; Intermediate base mineral oil: 10%; Water: 43.5%.

[0043] Specifically, according to weight percentage, it includes the following components: triethanolamine, diethanolamine, monoethanolamine mixture: 20%; suberic acid: 0.5%; isothiazolinone: 0.5%; aliphatic amine polyoxyethylene ether: 1.5% %; fatty acid sulfoalkylamides: 1.5%; lauryl phosphate: 1%; naphthenic mineral oil and castor oil unsaturated fatty acid esters: 10%; water: 43...

Embodiment 2

[0045] A kind of microemulsion cutting fluid described in this embodiment comprises the following components by weight parts:

[0046] PH value regulator: 15%, rust inhibitor: 1%, bacteriostatic agent: 1%, nonionic surfactant: 5%, anionic surfactant: 18%, corrosion inhibitor: 2%, base oil: 8 %, water: 50%.

[0047] Specifically include the following implementation methods:

[0048]Specifically, according to weight percentage, it includes the following components: triethanolamine, monoethanolamine mixture: 15%; azelaic acid: 1%; borate: 1%; oleic acid: 18%; Ether: 2%; Phosphodiester: 2%; Polyalphaolefin: 8%; Water: 50%.

[0049] Specifically, according to weight percentage, it includes the following components: mixture of cyclohexylamine and diethanolamine: 15%; sebacic acid: 1%; polyquaternium salt: 1%; alkylphenol polyoxyethylene ether: 2% ;Oleic Acid, Potassium Oleate Blend: 18%; Succinate Sulfonate: 2%; Polyphosphate: 2%; Sunflower Oil: 8%; Water: 50%.

[0050] Specific...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com