A kind of spodumene high-efficiency combined collector and its preparation method and application

A technology combining collector and spodumene, applied in solid separation, flotation and other directions, can solve the problems of difficult development of spodumene ore, unconverted resource advantages, high processing cost, etc., to achieve anti-sludge The effect of strong ability, low cost and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 50.0 parts of oxidized paraffin wax soap 733 powder, 15.0 parts of naphthenic acid soap, 15.0 parts of sodium fatty alcohol polyoxyethylene ether carboxylate, dodecyltrimethylammonium chloride and tributylmethylammonium chloride 1:1 (w / w) mixture of 20.0 parts is added to water whose weight is 9 times the total weight of the above substances, and then stirred for 20 minutes under the condition of constant temperature in a water bath at 50°C to obtain a combined collection of flotation spodumene with a concentration of 10.0% by mass agent.

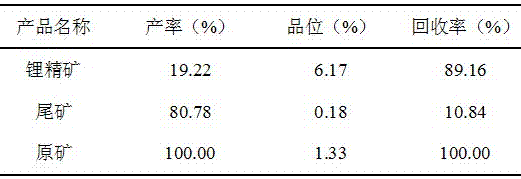

[0029] For a complex and rare pegmatite ore in the southwest of Aba Tibetan and Qiang Autonomous Prefecture, Sichuan, the main minerals are spodumene, beryl, lepidolite, muscovite, feldspar and quartz, etc. 2 The grade of O is 1.33%, add 500g / t of combined collector of the present invention, use it at a slurry temperature of 15°C, and the pH is 5.0-6.0 when used; the closed-circuit flotation after one roughing, two beneficiation, an...

Embodiment 2

[0033] 60.0 parts of oxidized paraffin wax soap 733 powder, 10.0 parts of naphthenic acid soap, 15.0 parts of fatty alcohol polyoxyethylene ether sodium carboxylate, dodecyl trimethyl ammonium chloride and dodecyl trimethyl ammonium chloride 1: Add 15.0 parts of a mixture of 1 (w / w) to water whose weight is 19 times the total weight of the above substances, and then stir for 30 minutes under the condition of constant temperature in a water bath at 60°C to obtain a flotation spodumene with a concentration of 5.0% by mass Combination collectors.

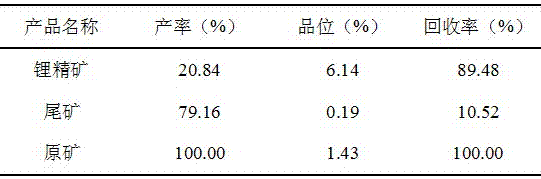

[0034] Aiming at the complex and rare pegmatite ore in Ganzi Prefecture, Sichuan Province, the main minerals are spodumene, beryl, niobium-tantalite, mica minerals, feldspar and quartz, etc., which were selected into the raw ore Li 2 The grade of O is 1.43%, add 400g / t of combined collector of the present invention, and use it at a pulp temperature of 10°C, and the pH is 7.0-8.0 when used; it is a closed-circuit flotation after one rou...

Embodiment 3

[0038] 55.0 parts of oxidized paraffin wax soap 733 powder, 12.0 parts of naphthenic acid soap, 13.0 parts of sodium fatty alcohol polyoxyethylene ether carboxylate, dodecyl dimethyl ethyl ammonium chloride and tributyl methyl ammonium chloride 1:1 ( w / w) 20.0 parts of the mixture was added to water whose weight was 7 times the total weight of the above substances, and then stirred for 25 minutes under the condition of constant temperature in a water bath at 60°C to obtain a combined collection of flotation spodumene with a concentration of 12.5% by mass agent.

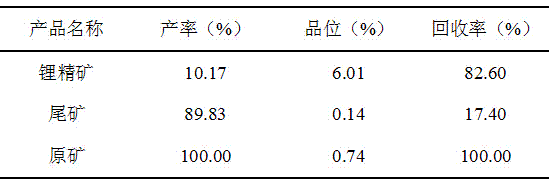

[0039] For a complex and rare pegmatite ore in Ganzhou City, Jiangxi Province, the main minerals are spodumene, beryl, mica minerals, feldspar and quartz, etc., which were selected into the raw ore Li 2 O grade is 0.74%, add 900g / t of the combined collector of the present invention, use it at a slurry temperature of 20°C, and the pH is 8.0-9.0 when used; the closed-circuit flotation after one roughing, two beneficia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com