Amorphous vanadium oxide film material containing V6O13 crystals and preparing method thereof

A technology of V6O13 and vanadium oxide film, which is applied in the field of materials, can solve the problems of impure composition, poor film uniformity, and incompatibility, and achieve the effect of simple preparation process, stable resistance change, and smooth and dense surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

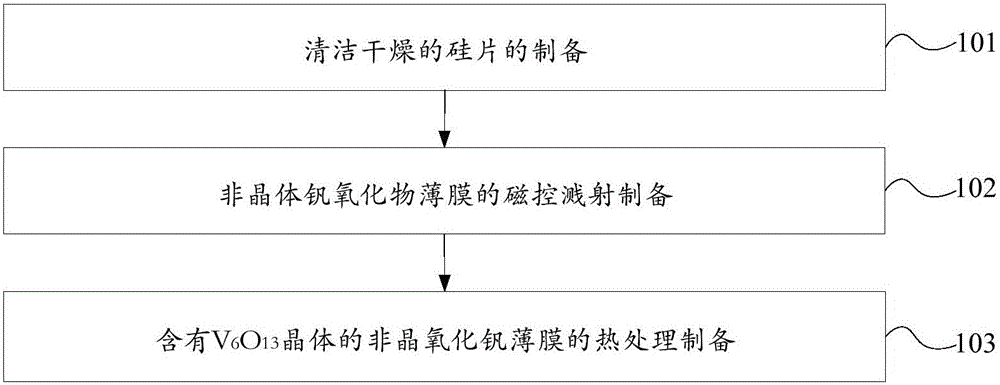

[0034] The present invention provides a kind of containing V 6 o 13 A method for preparing a crystalline amorphous vanadium oxide thin film material. refer to figure 1 , which shows that the preparation of the examples of the present invention contains V 6 o 13 A flowchart of a method for crystalline amorphous vanadium oxide thin films, the method comprising the following steps:

[0035] Step 101, preparation of the clean and dry silicon wafer.

[0036] Preparation of clean and dry silicon wafers: the silicon wafers were sequentially ultrasonically cleaned in concentrated hydrochloric acid with a purity of 99.99%, acetone, absolute ethanol, and deionized water for 20 to 30 minutes to remove impurities on the surface of the silicon substrate, and then cleaned The final silicon substrate is dried for future use.

[0037] The impurities on the surface of the silicon wafer are removed through the above treatment process, which prevents the impurities on the surface of the si...

Embodiment 1

[0054] The following examples all adopt MSP-620 automatic magnetron sputtering apparatus, the target material is a metal vanadium target with a purity of 99.999%, the substrate is a 2-4 inch silicon chip, and the silicon chip is directly sputtered by the metal vanadium target , The purity of oxygen and argon in the sputtering gas is 99.999%.

[0055] The silicon wafer was ultrasonically cleaned for 30 minutes in concentrated hydrochloric acid with a purity of 99.99%, acetone, absolute ethanol and deionized water in sequence, and then dried to obtain a clean and dry silicon wafer.

[0056] Put the clean and dry silicon wafer in the magnetron sputtering vacuum chamber, and evacuate the magnetron sputtering vacuum chamber to 9×10 -4 Pa; argon is the sputtering gas, and oxygen is the reaction gas, which are jointly fed into the chamber. The gas flow of argon is 40 sccm, and the gas flow of oxygen is 0.8 sccm; after feeding argon and oxygen, adjust the magnetron sputtering The vac...

Embodiment 2

[0059] The following examples all adopt MSP-620 automatic magnetron sputtering apparatus, the target material is a metal vanadium target with a purity of 99.999%, the substrate is a 2-4 inch silicon chip, and the silicon chip is directly sputtered by the metal vanadium target , The purity of oxygen and argon in the sputtering gas is 99.999%.

[0060] The silicon wafer was ultrasonically cleaned for 30 minutes in concentrated hydrochloric acid with a purity of 99.99%, acetone, absolute ethanol and deionized water in sequence, and then dried to obtain a clean and dry silicon wafer.

[0061] Put the clean and dry silicon wafer in the magnetron sputtering vacuum chamber, and evacuate the magnetron sputtering vacuum chamber to 0.5×10 -5Pa; the sputtering gas is argon, and oxygen is a reaction gas, which are jointly fed into the chamber, and the gas flow of argon is 55 sccm, and the gas flow of oxygen is 1.4 sccm; The vacuum degree in the vacuum chamber is 2Pa, the sputtering power...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Room temperature resistance | aaaaa | aaaaa |

| Room temperature resistance | aaaaa | aaaaa |

| Temperature coefficient of resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com