Preparation method of membrane adsorbent for removing ammonia nitrogen in wastewater

A membrane adsorption and ammonia nitrogen technology, applied in chemical instruments and methods, adsorption water/sewage treatment, membrane technology, etc., to achieve stable mechanical and thermodynamic properties, increase porosity, and reduce solvent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

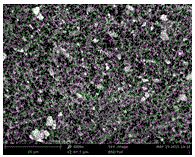

Image

Examples

preparation example Construction

[0016] The modified water purification sludge used in embodiment 1-5 is prepared by the following method:

[0017] 1. In a three-necked flask, add 24g of dried water purification sludge, 18g of sodium silicate, and 200mL of 2mol / L sodium hydroxide solution. h;

[0018] 2. Centrifuge the contents of the three-necked bottle, take its supernatant, adjust the pH value of the supernatant to 8 with concentrated sulfuric acid under mechanical stirring, then perform suction filtration, and take its filter cake;

[0019] 3. Add 10mL of distilled water to the filter cake, put it into a high-pressure reactor lined with polytetrafluoroethylene, react at 105°C for 3 hours, take out the filter cake by suction filtration and put it in an evaporating dish, and dry it in an oven at 100°C. The modified water purification sludge is obtained.

[0020] The water purification sludge used is taken from the Suzhou New District Waterworks.

Embodiment 1

[0022] A preparation method of a membrane adsorbent for removing ammonia nitrogen in waste water, the preparation steps are as follows:

[0023] (1) Treatment of modified water purification sludge: Grinding, crushing and sieving the modified water purification sludge to produce ultrafine sludge particles with an average particle size of 1 μm;

[0024] (2) Preparation of casting solution: Add 0.9g polyvinylpyrrolidone into a conical flask containing 23.7mL dimethylacetamide, mix and stir evenly, add 3.78g polyvinylidene fluoride after the polyvinylpyrrolidone dissolves, keep The temperature is 50-70°C. After polyvinylidene fluoride is dissolved, add 1.62g of the above sludge particles (polyvinylidene fluoride / modified water purification sludge particles=7:3), stir for 6 hours, and seal with plastic wrap bottle mouth, stand for degassing for 24 hours to obtain the casting solution;

[0025] (3) Preparation of membrane adsorbent: Control the temperature of the glass plate at 25°...

Embodiment 2

[0028] A preparation method of a membrane adsorbent for removing ammonia nitrogen in waste water, the preparation steps are as follows:

[0029] (1) Treatment of modified water purification sludge: Grinding, crushing and sieving the modified water purification sludge to produce ultrafine sludge particles with an average particle size of 1 μm;

[0030] (2) Preparation of casting solution: Add 0.9g polyvinylpyrrolidone into a conical flask containing 23.7mL dimethylacetamide, mix and stir evenly, add 3.24g polyvinylidene fluoride after the polyvinylpyrrolidone dissolves, keep The temperature is 50-70°C. After polyvinylidene fluoride is dissolved, add 2.16g of the above sludge particles (polyvinylidene fluoride / modified water purification sludge particles=6:4), stir for 6 hours, and seal with plastic wrap bottle mouth, stand for degassing for 24 hours to obtain the casting solution;

[0031] (3) Preparation of membrane adsorbent: Control the temperature of the glass plate at 25°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com