A kind of preparation method and use of titanium cobalt spinel

A technology of spinel and cobalt titanate is applied in the field of preparation of titanium cobalt spinel, which can solve the problems of difficulty in controlling particle morphology and size, inability to obtain regular morphology, and restricting the application of materials. Excellent cycle stability, easy operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] Preparation method, it comprises the following steps:

[0032] (1) The cobalt source is divalent cobalt salt, selected from hydrated cobalt chloride (CoCl 2 ·6H 2 O), cobalt oxalate hydrate (CoC 2 o 4 2H 2 O), hydrated cobalt acetate (C 4 h 6 o 4 ·Co·4H 2 O) or cobalt nitrate hydrate (Co(NO 3 ) 2 ·6H 2 O);

[0033] The titanium source is selected from titanium dioxide (TiO 2 ), butyl titanate (C 16 h 36 o 4 Ti) or hydrated titanium sulfate (Ti(SO 4 ) 2 9H 2 O);

[0034] Solution 1 is prepared by adding titanium source to 0.5-2 mol / L lye; adding cobalt source to a solution with a mass ratio of sugar adjuvant: amine adjuvant = 2:1 to obtain solution 2. Mix solution 1 and solution 2 according to the molar ratio (1-5) of cobalt source and titanium source: 1 and stir evenly;

[0035] (2) Move the mixed material obtained in step (1) into a closed reactor at 100-250°C, react for 8-40 hours, cool naturally to room temperature, and then separate and purify to...

Embodiment 1

[0046] Example 1: Preparation and structural characterization of titanium-cobalt spinel nano-octahedron

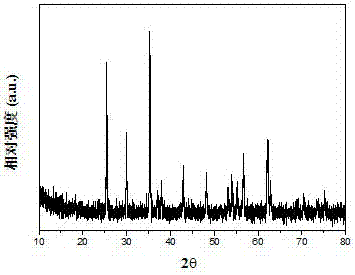

[0047] Take 0.06g TiO 2 and 1.2g NaOH are put into the container and add 30ml deionized water to be mixed with suspension 1, get 0.3 g cobalt chloride hydrate (CoCl 2 ·6H 2 O), 0.1 g glucose and 0.05 g hydroxylamine chloride (H 3 NO·HCl) into a container and add 10ml of distilled water to make solution 2; mix and stir the suspension 1 and solution 2 evenly and transfer the mixed material to a closed pressure-resistant reaction vessel for reaction at 200°C 48 hours. Then cool to room temperature, open the airtight reaction vessel, and filter with Buchner funnel, wash with deionized water and absolute ethanol repeatedly to obtain a dark green powder product. The product was identified as cubic titanium-cobalt spinel Co 2 TiO 4 ( figure 1 ), which matches the JCPDS card standard value No. 39-1410, and no other impurity peaks appear.

[0048] figure 1 It is the powder...

Embodiment 2

[0052] Embodiment 2: get 0.06g TiO 2 and 1.2g NaOH are put into container and add 30ml deionized water and be mixed with suspension 1, get 0.31 g hydrated cobalt acetate (C 4 h 6 o 4 ·Co·4H 2 O), 0.2 g glucose and 0.1 g hydroxylamine chloride (H 3 NO·HCl) into a container and add 10ml of distilled water to prepare solution 2; mix and stir the suspension 1 and solution 2 evenly, transfer the mixed material to a closed pressure-resistant reaction vessel, and react at 180°C 48 hours. Then cool to room temperature, open the airtight reaction vessel, and repeatedly centrifuge and wash with deionized water and absolute ethanol to obtain a dark green powder product.

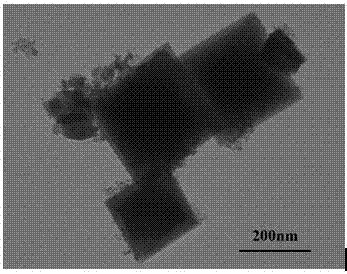

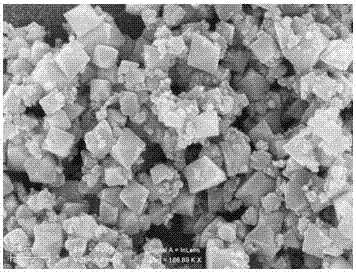

[0053] The obtained ultrafine powder is cubic titanium-cobalt spinel (JCPDS No. 39-1410), with good crystallinity; the product is composed of nano-octahedrons with an average particle size of about 170 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com