Natural preservative children plant sunscreen lotion and preparation method thereof

A natural antiseptic and children's technology, applied in the field of daily care products, can solve the problems of skin allergies, redness and inflammation, easy light or oxidative degradation, poor photostability of sunscreens, etc. High safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

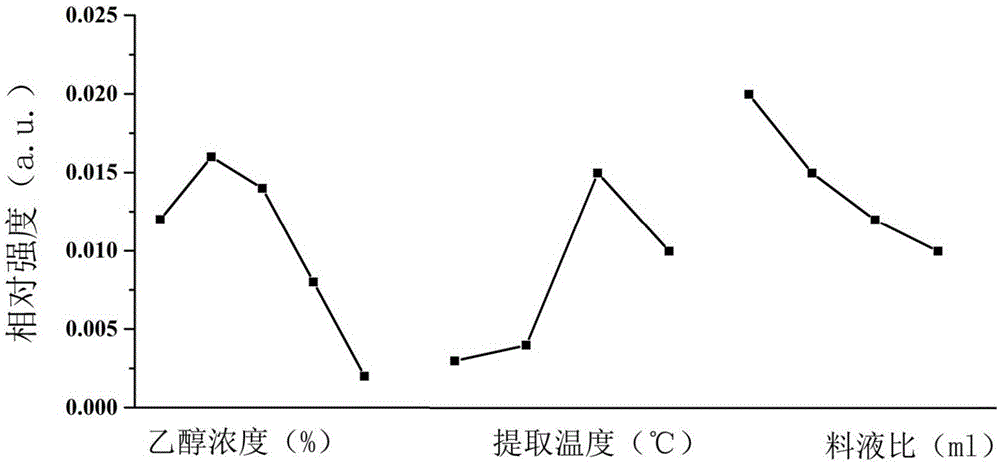

[0033] Take 6g of dry aloe vera skin powder and add 30 times the mass of the extraction solvent. The mass fractions of the solvent are 20%, 30%, 40%, 50% and 60% ethanol solution, at a temperature of 25℃±3℃ Carry out ultrasonic extraction for about 30 minutes. After fully filtering with 0.22nm organic filter paper, take the filtrate, concentrate the filtrate to 0.3 times in a rotary evaporator, and transfer it to a vacuum drying oven at 55°C to obtain a fluffy solid. After being ground into powder, 5 times the mass of deionized water is added to dissolve to obtain an aloe extract for later use. Take 1.5ml of aloe extract and dilute to 5ml with absolute ethanol, take 1ml of diluent and react with 1ml of 2% magnesium acetate methanol solution for 30 minutes and then dilute to 10ml with deionized water. Use a 1cm cuvette to measure the difference in absorbance at 420nm before and after the reaction with the volume ratio of deionized water: methanol = 9:1 as a reference. The relati...

Embodiment 2

[0035] Take 6g of dry aloe skin powder, add 30 times the mass of extraction solvent, the choice of solvent is 60% ethanol solution, and perform ultrasonic extraction at 25℃, 35℃, 45℃ and 55℃ for about 30 minutes. After fully filtering the 0.22nm organic filter paper, take the filtrate, concentrate the filtrate on a rotary evaporator to 0.3 times, transfer it to a vacuum drying oven at 55℃ and dry to obtain a fluffy solid, grind it into powder and add 5 times the mass Dissolve in deionized water to obtain aloe extract for use. Take 1.5ml of aloe extract and dilute to 5ml with absolute ethanol, take 1ml of diluent and react with 1ml of 2% magnesium acetate methanol solution for 30 minutes and then dilute to 10ml with deionized water. Use a 1cm cuvette to measure the difference in absorbance at 420nm before and after the reaction with a mixture of deionized water: methanol = 9:1 in volume ratio as a reference. The relative intensity of the absorbance varies with extraction tempera...

Embodiment 3

[0037] Take 6g of dry aloe vera skin powder, add 10 times, 20 times, 30 times and 40 times the mass of the extraction solvent respectively. The choice of solvent is 40% ethanol solution, and perform ultrasonic extraction at 45℃±3℃ for 30 minutes Take the filtrate after fully filtering it with 0.22nm organic filter paper. Concentrate the filtrate to 0.3 times in a rotary evaporator, transfer it to a vacuum drying oven at 55°C and dry to obtain a fluffy solid, grind it into powder and add it 5 times the mass of deionized water is dissolved to obtain an aloe extract for use. Take 1.5ml of aloe extract and dilute to 5ml with absolute ethanol, take 1ml of diluent and react with 1ml of 2% magnesium acetate methanol solution for 30 minutes and then dilute to 10ml with deionized water. Use a 1cm cuvette to measure the difference in absorbance at 420nm before and after the reaction with a mixture of deionized water: methanol = 9:1 in volume ratio as a reference. The relative intensity o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com