Polymeric microspheres and preparation method therefor

A technology of polymers and microspheres, applied in the field of biomimetic materials, can solve the problems of difficult washing and removal, polymers containing cross-linking agents, and difficulty in obtaining microsphere materials with an extracellular matrix-like structure, etc., and achieve good adhesion. Proliferative properties, high purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

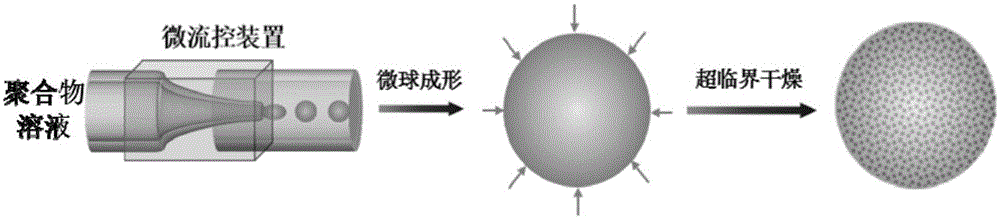

[0026] The invention provides a method for preparing polymer microspheres, comprising:

[0027] The emulsified polymer droplets are mixed with a solution containing a fixative to obtain polymer microspheres through physical cross-linking.

[0028] According to the present invention, the present invention obtains polymer microspheres through physical crosslinking by mixing emulsified polymer droplets with a solution containing a fixative;

[0029] Wherein, the polymer in the emulsified polymer droplets is preferably one or more of chitosan, collagen, silk protein, gelatin and sodium alginate, more preferably chitosan or sodium alginate;

[0030] The solution containing the fixing agent is alcohol solution of sodium hydroxide, alcohol solution of potassium hydroxide, alcohol solution of calcium chloride, alcohol solution of calcium nitrate, acetone or methanol; the alcohol in the alcohol solution is methanol and ethanol One or both of them; when the solution containing the fixi...

Embodiment 1

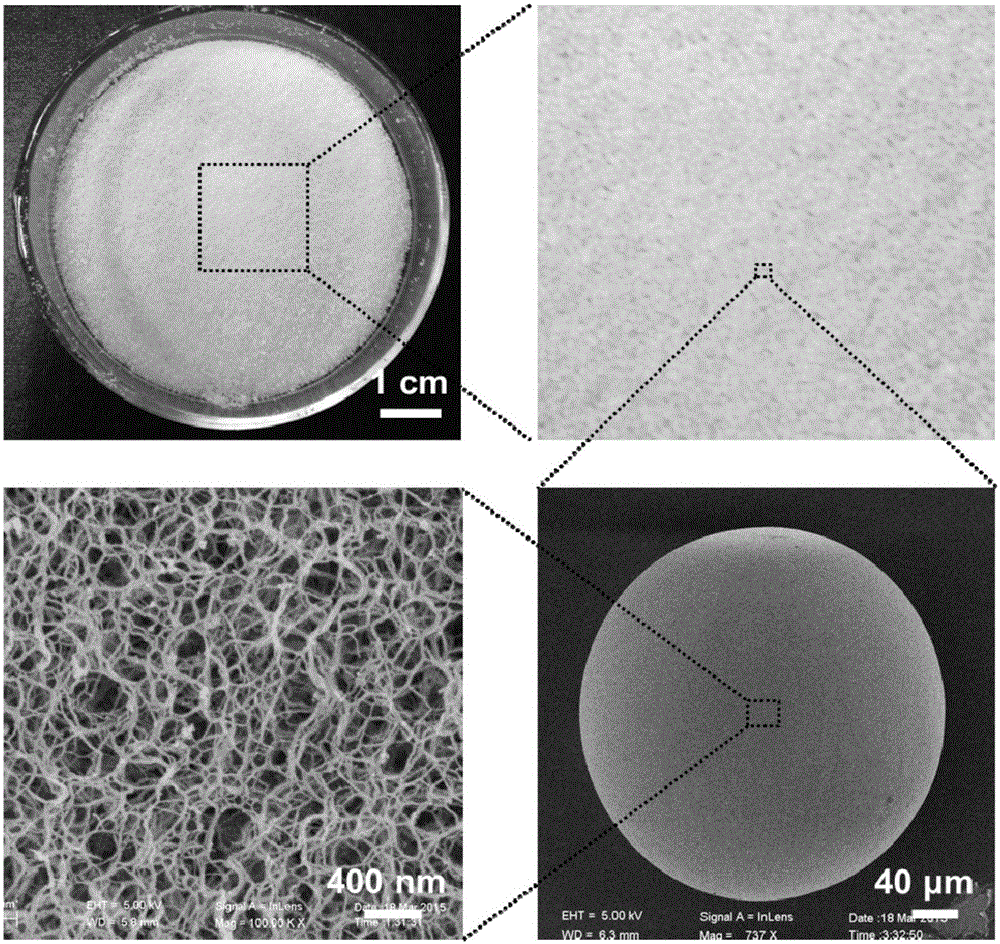

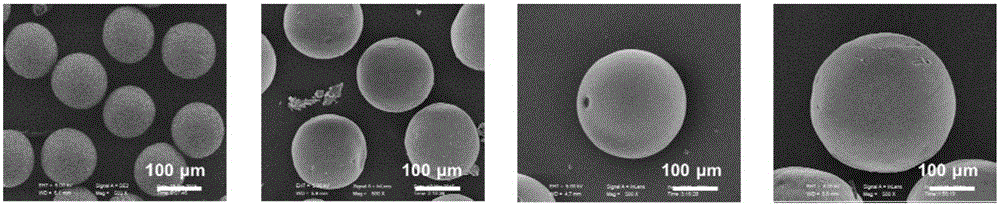

[0040] Weigh 0.5g of chitosan and dissolve it in 50ml of 1% acetic acid aqueous solution to prepare a uniform chitosan aqueous solution; use a 10ml syringe to extract 5-8ml of the prepared chitosan solution and insert it into the inner tube of the tube-in-tube microfluidic device Utilize a 100ml syringe to extract 50-80ml cyclohexane (containing 3% Span-80) as the extrusion phase, and insert it into the outer tube of the tube casing microfluidic device; The diameter of the tube is 60 microns, the extrusion speed is 0.01ml / min, the outer tube is directly 300 microns, and the extrusion speed is 0.4ml / min), the NaOH ethanol solution of 0.3mol / L is prepared as a solution containing a fixative to collect the extruded liquid microspheres; obtaining cross-linked chitosan microspheres with a diameter of 100 micrometers; washing the cross-linked chitosan microspheres with ethanol and finally supercritical drying to obtain chitosan microspheres.

[0041] In the same way, by controlling ...

Embodiment 2

[0047] Weigh 0.5g of sodium alginate and dissolve it in 50ml of water to prepare a uniform sodium alginate aqueous solution; use a 10ml syringe to extract 5-8ml of the prepared sodium alginate solution, insert it into the inner tube of the tube-in-tube microfluidic device, and use a 100ml syringe Extract 50-80ml cyclohexane (containing 3% Span-80) as the extrusion phase, insert the outer tube of the tube casing microfluidic device; use a micro injection pump to control the extrusion speed of the two syringes respectively (the inner tube is directly 60 microns , the extrusion speed is 0.03ml / min, the outer tube is directly 300 microns, the extrusion speed is 0.6ml / min), and the CaCl of 0.01mol / L is prepared 2 The ethanol solution is used as a solution containing a fixative to collect the extruded liquid microspheres; obtain cross-linked sodium alginate microspheres; wash the cross-linked sodium alginate microspheres with ethanol and finally undergo supercritical drying to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com