Red fluorescence powder for laser medical-treatment illumination and preparation method and application thereof

A technology for red phosphor powder and laser medical treatment, applied in the field of red phosphor powder, can solve the problem of red LED light saturation, etc., and achieve the effect of promoting synthesis, good luminous efficiency, and realizing spectrum tunable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

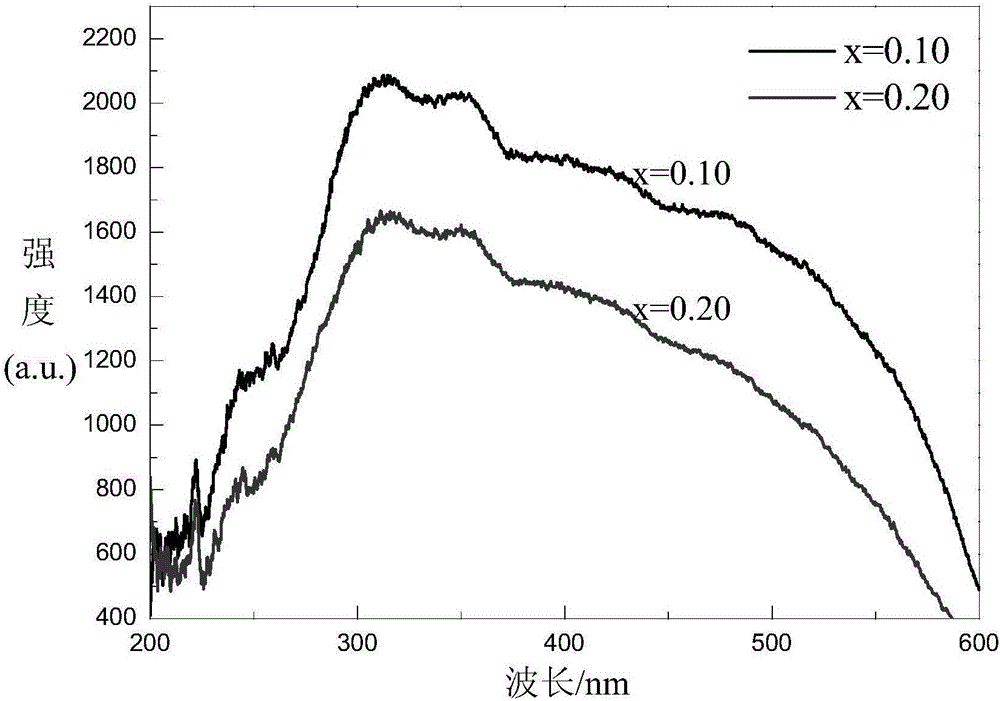

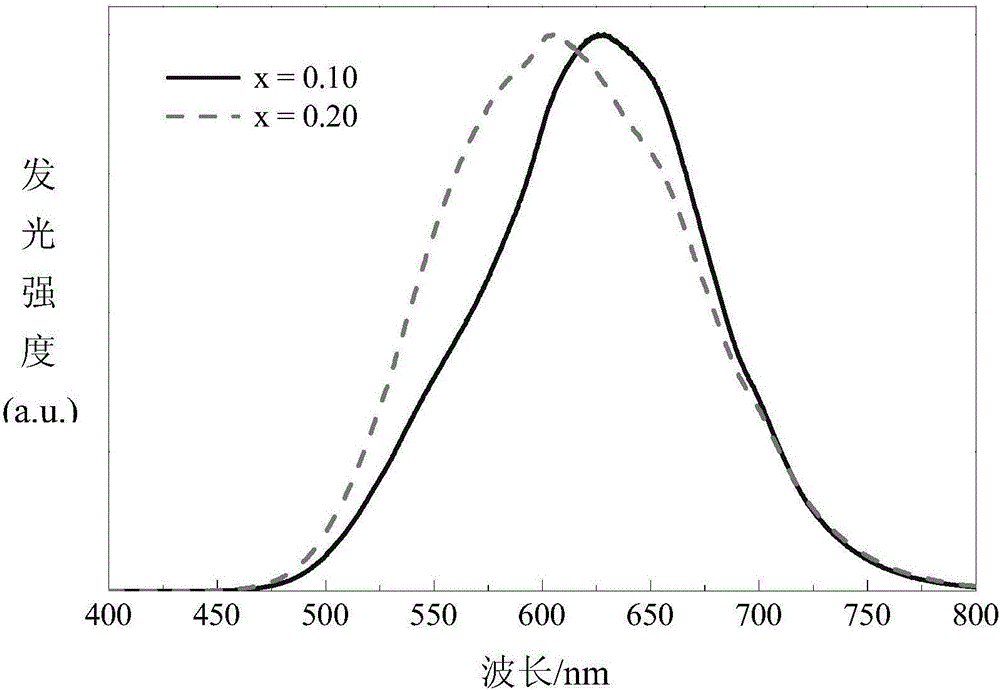

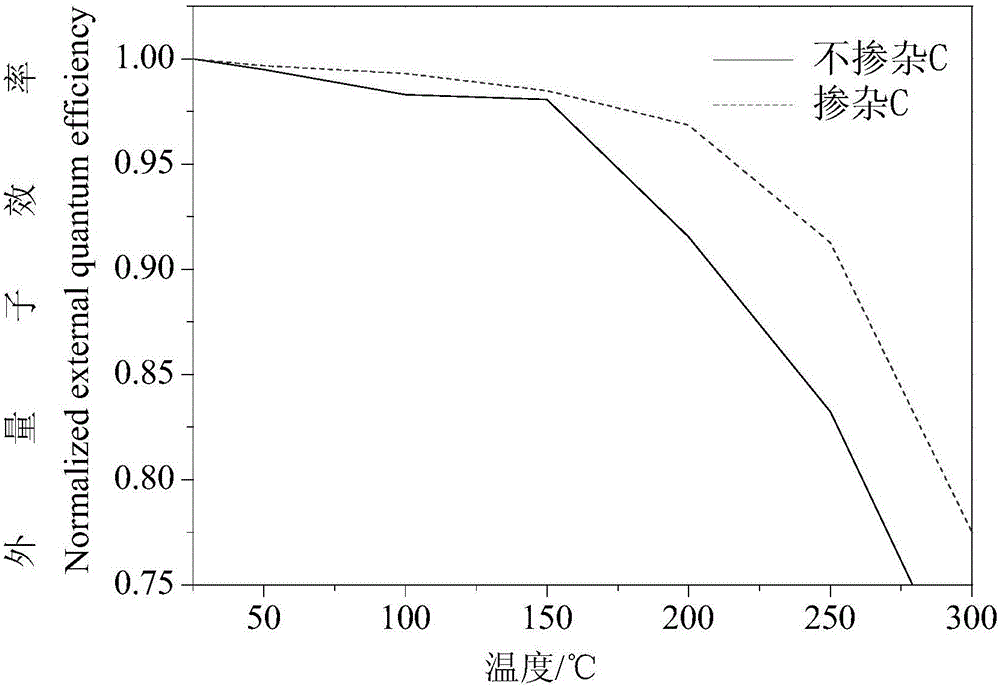

[0038] Without adding flux, doped with 0.10mol of Li atoms, 0.10mol of C atoms, 0.89mol of Ca atoms, the molar amount of Li doping is 0.10, and the high temperature solid phase method is used to prepare Ca 0.89 Li 0.1 Al 0.8 Si 1.2 N 2.9 C 0.1 :0.01Eu 2+ Phosphor.

[0039] According to the stoichiometric ratio, accurately weigh 32.6wt% calcium nitride (Ca 3 N 2 ), 38.1wt% silicon nitride (Si 3 N 4 ), 0.8wt% lithium nitride (Li 3 N), 24.3wt% aluminum nitride (AlN), 3.0wt% silicon carbide (SiC), 1.2wt% europium nitride (EuN) raw materials, put them in a mortar, thoroughly mix, grind and mix, and the resulting particles are uniform Move the powder into the crucible and fill it with a volume percentage of 95% N 2 And 5% H 2 High-temperature carbon tube furnace with reducing atmosphere, the calcination temperature is set to 1800℃, and the calcination time is 2h. After the furnace is cooled to room temperature 25°C, take out the sample, put it in a mortar and grind evenly to obtain high...

Embodiment 2

[0041] Without adding flux, doped with 0.20mol of Li atoms, 0.10mol of C atoms, and 0.89mol of Ca atoms to prepare Ca by high temperature solid phase method 0.79 Li 0.2 Al 0.7 Si 1.3 N 2.9 C 0.1 :0.01Eu 2+ Phosphor.

[0042] According to the stoichiometric ratio, accurately weigh 29.6wt% calcium nitride (Ca 3 N 2 ), 42.5wt% silicon nitride (Si 3 N 4 ), 1.8wt% lithium nitride (Li 3 N), 21.8wt% aluminum nitride (AlN), 3.0wt% silicon carbide (SiC), 1.3wt% europium nitride (EuN) raw materials, put them in a mortar, thoroughly mix, grind and mix, and the resulting particles are uniform Move the powder into the crucible and fill it with a volume percentage of 95% N 2 And 5% H 2 High-temperature carbon tube furnace with reducing atmosphere, the calcination temperature is set to 1800℃, and the calcination time is 2h. After the furnace is cooled to room temperature 25°C, take out the sample, put it in a mortar and grind evenly to obtain high purity Ca 0.79 Li 0.2 Al 0.7 Si 1.3 N 2.9 C 0.1 ...

Embodiment 3

[0044] Example 3 (for comparison)

[0045] Without adding flux, only 0.10mol of Li atoms and 0.89mol of Ca atoms are doped, and Ca is prepared by high temperature solid phase method 0.89 Li 0.1 Al 0.9 Si 1.1 N 3 :0.01Eu 2+ Phosphor.

[0046] Follow Ca 0.89 Li 0.1 Al 0.9 Si 1.1 N 3 :0.01Eu 2+ The stoichiometric ratio of the phosphor, accurately weighing 32.5wt% calcium nitride (Ca 3 N 2 ), 38.1wt% silicon nitride (Si 3 N 4 ), 0.9wt% lithium nitride (Li 3 N), 27.3wt% aluminum nitride (AlN), 1.2wt% europium nitride (EuN) raw materials, put them in a mortar, thoroughly mix, grind, and mix, and transfer the resulting uniform powder into the crucible and fill it with Percentage by volume 95% N 2 And 5% H 2 High-temperature carbon tube furnace with reducing atmosphere, the calcination temperature is set to 1800℃, and the calcination time is 2h. After the furnace is cooled to room temperature 25°C, take out the sample, put it in a mortar and grind evenly to obtain high purity Ca 0.89 Li 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com