Method for preparing interconnected and folded graphene materials for super-capacitor

A supercapacitor, interconnected technology, applied in the field of carbon material preparation, can solve the problems of high energy consumption, large pollution, and difficult separation in the separation process, and achieve the effects of good cycle stability, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

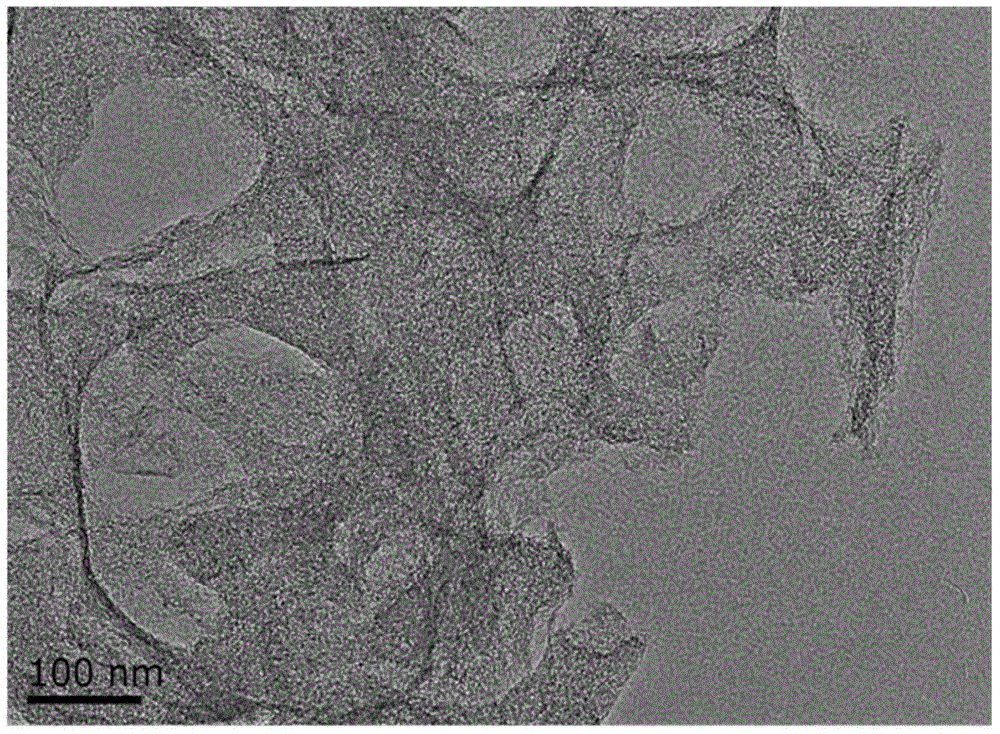

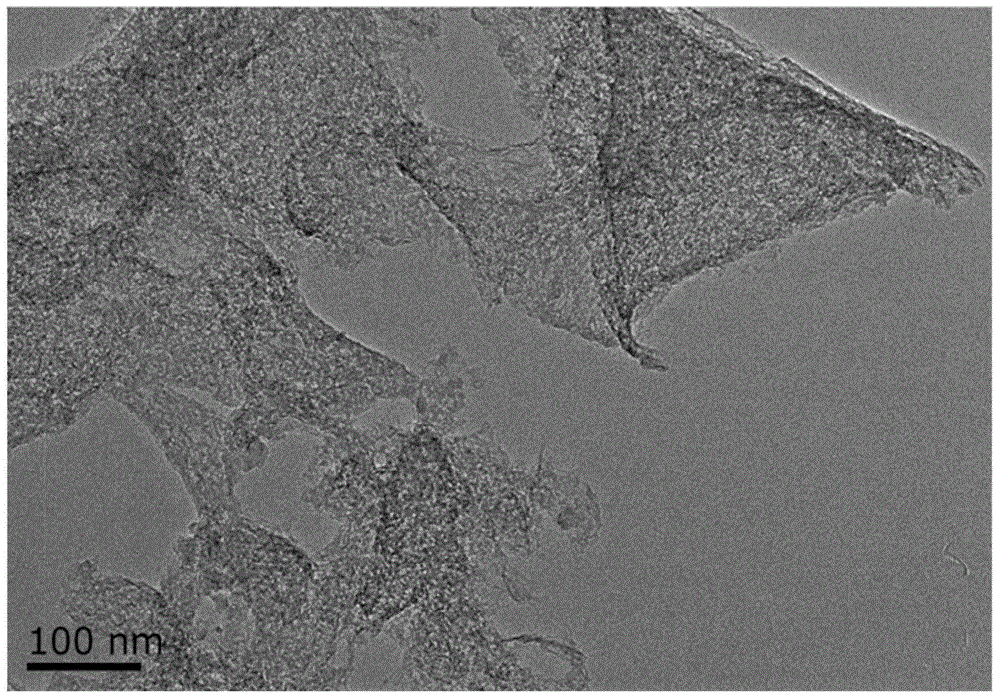

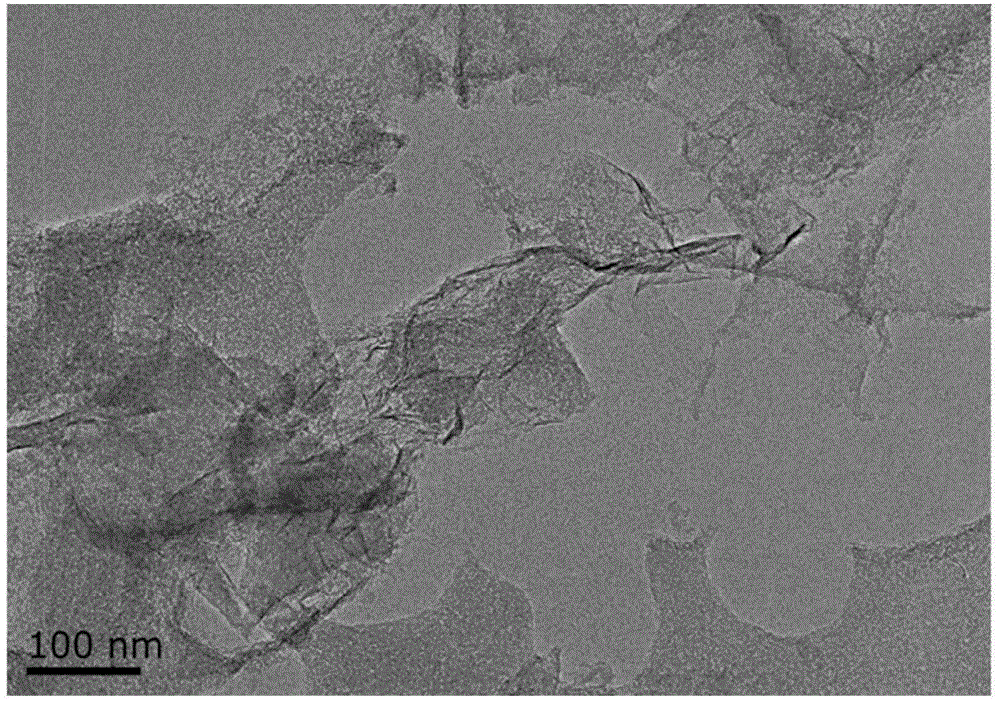

Image

Examples

Embodiment 1

[0022] Interconnected and wrinkled graphene material IFCG 9-800 The specific preparation process is as follows:

[0023] (1) Pretreatment of reactants: Weigh 12g KOH solids and put them in a mortar, grind and pulverize them, add 9g nano-magnesia powder, mix the two evenly to obtain a mixed powder, add the gained mixed powder to a container containing 6g anthracene In a beaker of oil, add 2.6g N, N-dimethylformamide dropwise to the beaker to dissolve, supplemented by a glass rod to continuously stir, the resulting mixture is ultrasonically oscillated for 1h, and left to stand for 12h to obtain the reactant;

[0024] (2) Preparation of interconnected and wrinkled graphene materials: the reactant obtained in step (1) is put into a corundum porcelain boat, and then the porcelain boat is placed in a tube furnace at a rate of 60mL / min After the air in the tube furnace is exhausted by introducing argon gas, under the flowing argon atmosphere, heat the tube furnace to 300 °C at a hea...

Embodiment 2

[0026] Interconnected and wrinkled graphene material IFCG 9-850 The specific preparation process is as follows:

[0027] (1) Pretreatment of reactant: implement according to the same method as step (1) in Example 1;

[0028] (2) Preparation of interconnected and wrinkled graphene material: implemented in the same manner as step (2) in Example 1, except that the final heating temperature was 850°C. The resulting interconnected and wrinkled graphene material is labeled IFCG 9-850 . IFCG 9-850 Used as a symmetrical supercapacitor electrode material, in BMIMPF 6 In the electrolyte, at a current density of 0.05A / g, IFCG 9-850 The specific volume is 149F / g, and the available energy density is 82Wh / kg.

Embodiment 3

[0030] Interconnected and wrinkled graphene material IFCG 9-900 The specific preparation process is as follows:

[0031] (1) Pretreatment of reactants: implement according to the same method as step (1) in Example 1.

[0032] (2) Preparation of interconnected and wrinkled graphene materials: implemented in the same manner as step (2) in Example 1, except that the final heating temperature was 900°C. The resulting interconnected and wrinkled graphene material is labeled IFCG 9-900 . IFCG 9-900 Used as a symmetrical supercapacitor electrode material, in BMIMPF 6 In the electrolyte, at a current density of 0.05A / g, IFCG 9-900 The specific volume is 231F / g, and the available energy density is 128Wh / kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com