Biomimetic multifunctional coating for magnesium-based medical materials and devices, preparation and application

A multi-functional coating and device technology, applied in coating, medical science, surgery, etc., can solve the problems of surface modification, modification effect, film defects, matrix magnesium corrosion, etc., and slow down the degradation rate in vitro. , Biocompatibility improvement, the effect of improving biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

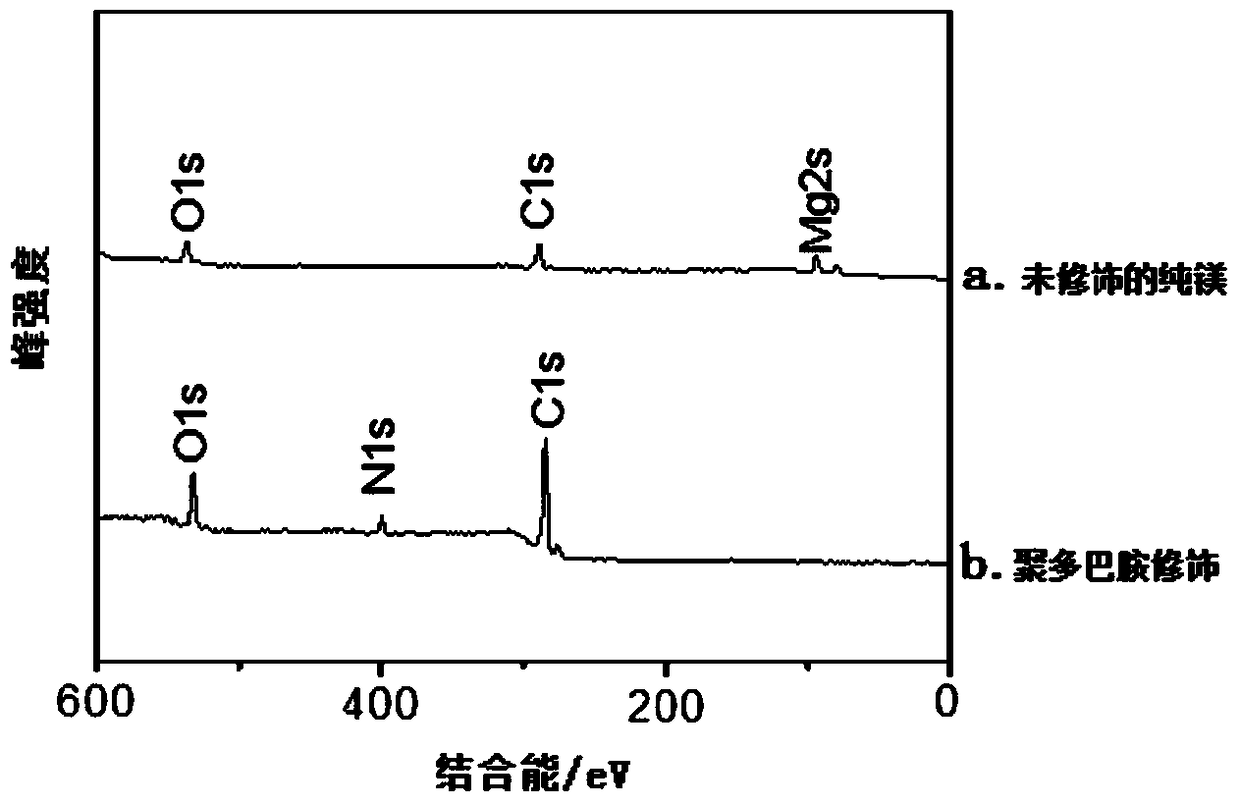

[0040] Add 0.2wt%-5wt% triethylamine into ethanol, stir and mix evenly. Dissolve dopamine hydrochloride in the above-mentioned ethanol solution containing triethylamine at a ratio of 1 mg / mL, and stir to fully dissolve. Immerse the pure Mg disc sample in the dopamine solution, soak at 30°C for 18 hours, take it out, wash it with isopropanol and ultrapure water in sequence, and dry it with nitrogen after ultrasonication for 1 minute. figure 1 The XPS detection in the middle shows that the surface components of magnesium after surface modification are mainly C, N and O, and the contents are consistent with the polydopamine reported in the literature, and the substrate Mg signal basically disappears (<2wt%). It was proved that a layer of dense polydopamine film was successfully prepared on the surface of pure magnesium. The results of ellipsometry showed that the thickness of the polydopamine film was about 22nm. The mechanical property test results show that the polydopamine c...

Embodiment 2

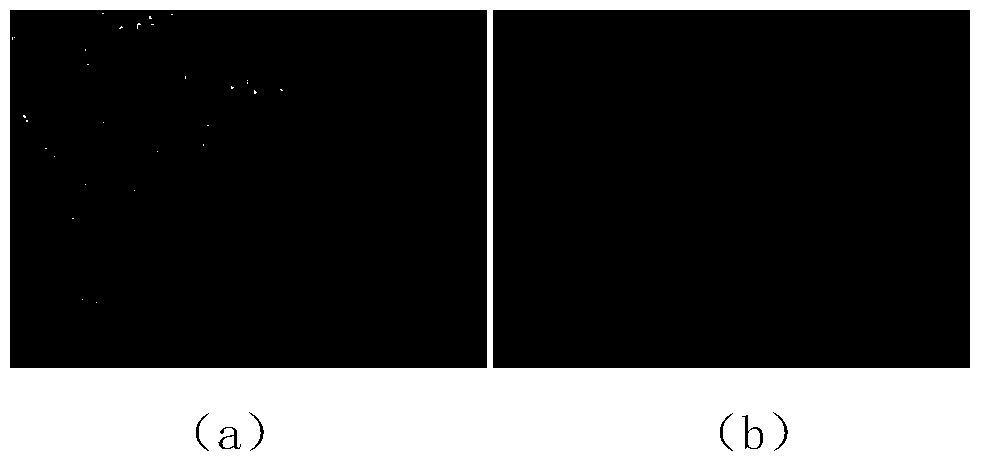

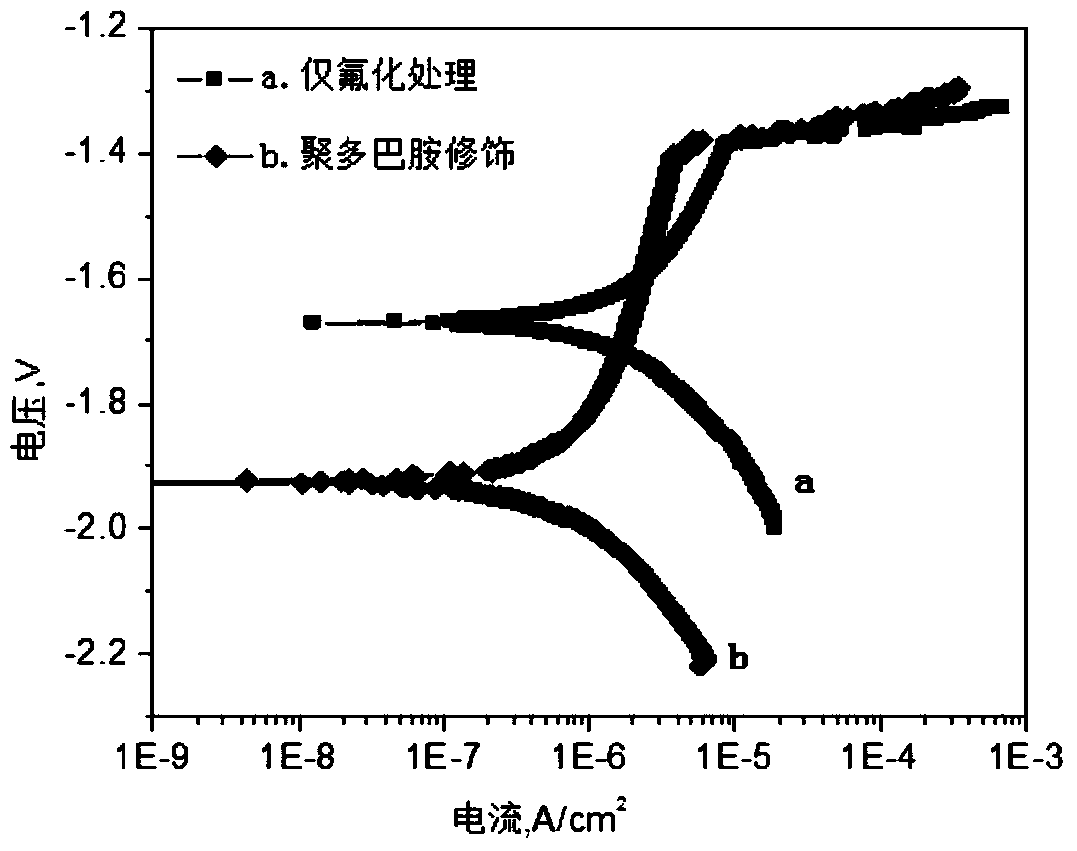

[0042] Add 0.3wt%-3wt% sodium hydroxide solid into the isopropanol solution, stir to dissolve. Dissolve dopamine hydrochloride in the above solution at a ratio of 4 mg / mL, and stir to fully dissolve. The fluorinated pretreated Mg-Nd-Zn-Zr alloy disc samples were immersed in the dopamine solution, soaked at 40°C for 24 hours, taken out, washed with ethanol and ultrapure water in sequence, ultrasonicated for 1 minute, and then blown dry with nitrogen. The sample prepared by this method has a smooth and complete surface under the SEM observation, while the sample prepared in aqueous solution for 24 hours according to US Patent 20080149566 and Chinese Patent CN102000658B method presents obvious cracks ( figure 2 ), it can be seen that the preparation in an aqueous solution environment leads to obvious degradation and corrosion of the magnesium matrix, and the obtained polydopa film layer is not dense and complete, and has crack-like defects; while the structure of the matrix and ...

Embodiment 3

[0044] Add ethylenediamine into tetrahydrofuran at a ratio of 0.1wt%-3wt%, and mix well. Dissolve dopamine hydrochloride in the above solution at a ratio of 2 mg / mL, and stir to fully dissolve. Immerse the untreated AZ31 (Mg-Al) alloy bone plate sample in dopamine solution, soak it on a shaker at 25°C for 8 hours, take it out, wash it with ethanol and ultrapure water in sequence, ultrasonicate it for 1 minute, and blow it dry with nitrogen. The results of ellipsometry showed that the thickness of the polydopamine film was about 15nm. The mechanical property test results show that the polydopamine coating has a strong binding force with the substrate, exceeding 12MPa. Using ICP-AES to detect the content of magnesium ions in the three-day extract, the degradation rate of the sample modified polydopamine film was about 64% lower than that of the AZ31 alloy sample. The cytotoxicity test results of osteoblast MC3T3 showed that the cytotoxicity of the sample modified with polydopa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com