Preparation method of betaine

A technology of betaine and glycine methyl ester, applied in the chemical industry, can solve the problems of no operational significance, destroying the quality of betaine, unfavorable large-scale production, etc., and achieves the effects of easy large-scale popularization and application, high safety and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

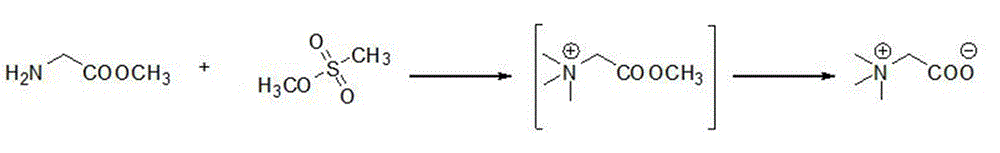

[0018] The chemical reaction equation involved in this embodiment is as figure 1 As shown, the specific steps are:

[0019] A. Add 89g glycine methyl ester, 1780g acetonitrile and 302.4g sodium bicarbonate in the three-necked flask that reflux condenser, thermometer, constant pressure dropping funnel and magnetic stirring device are housed, fully stir stand-by;

[0020] B. Add 363g methyl methanesulfonate dropwise under stirring, after the addition is completed, gradually rise to room temperature, heat to reflux and fully stir for 32 hours;

[0021] C. After the reaction finishes, adding concentration under stirring is 890g of 5% aqueous sodium hydroxide solution, and now the volume of the reaction solution is denoted as V, then warming up to 50°C, stirring and reacting for 20 hours, removing most of the solvent by distillation after the reaction finishes, Concentrate the volume to 28% V, filter to remove insoluble matter, and pass the filtrate through an ionic macroporous ad...

Embodiment 2

[0025] A. Add 89g glycine methyl ester, 750g acetonitrile and 252g sodium bicarbonate in the three-necked flask that reflux condenser, thermometer, constant pressure dropping funnel and magnetic stirring device are housed, fully stir stand-by;

[0026] B. Add 330 g of methyl methanesulfonate dropwise while stirring, after the addition is completed, gradually rise to room temperature, heat to reflux and fully stir for 16 hours.

[0027] C. After the reaction is over, add 890g of sodium hydroxide aqueous solution with a mass fraction of 5% under stirring, measure the reaction solution at this time and record it as V, then raise the temperature to 50°C and stir for 20 hours. After the reaction, remove most of the solvent by distillation , the volume is concentrated to 32% V, the insoluble matter is removed by filtration, the residual liquid is passed through ionic macroporous adsorption resin D101 to remove inorganic salt ions to obtain an aqueous solution of betaine, most of the ...

Embodiment 3

[0030] a. Add 89g, methyl glycine, 1000g acetonitrile and 277.2g sodium bicarbonate in a three-necked flask equipped with a reflux condenser, a thermometer, a constant pressure dropping funnel and a magnetic stirring device, and fully stir for use;

[0031] b. While stirring, 346.5 g of methyl methanesulfonate was added dropwise, and after the addition was completed, the temperature was gradually raised to room temperature, then heated to reflux and fully stirred and reacted for 24 hours.

[0032] c. After the reaction was over, add 890g of aqueous sodium hydroxide solution with a mass fraction of 5% under stirring, record the volume of the reaction solution as V, then raise the temperature to 50°C and stir for 20 hours. After the reaction, most of the solvent was removed by distillation, and the volume Concentrate to 30% V, filter to remove insoluble matter, the residual liquid passes through ionic macroporous adsorption resin D101 to remove inorganic salt ions to obtain be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com