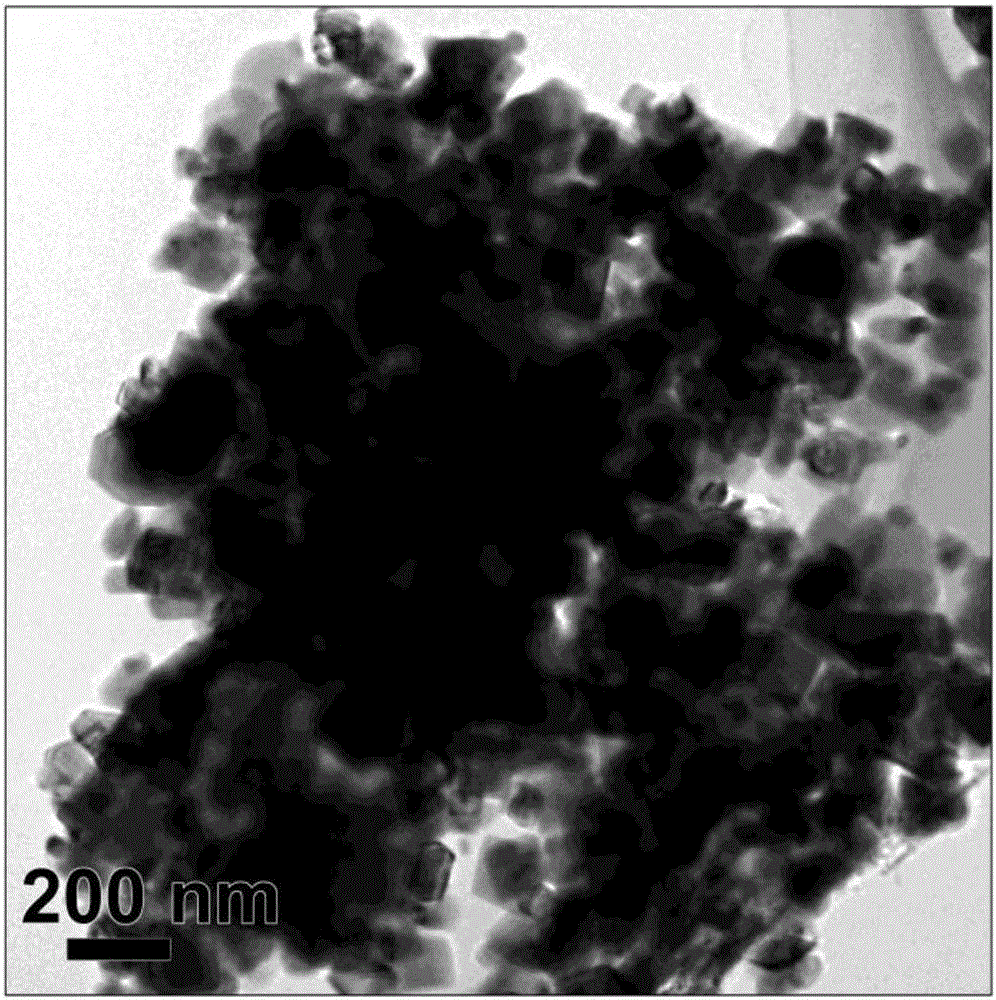

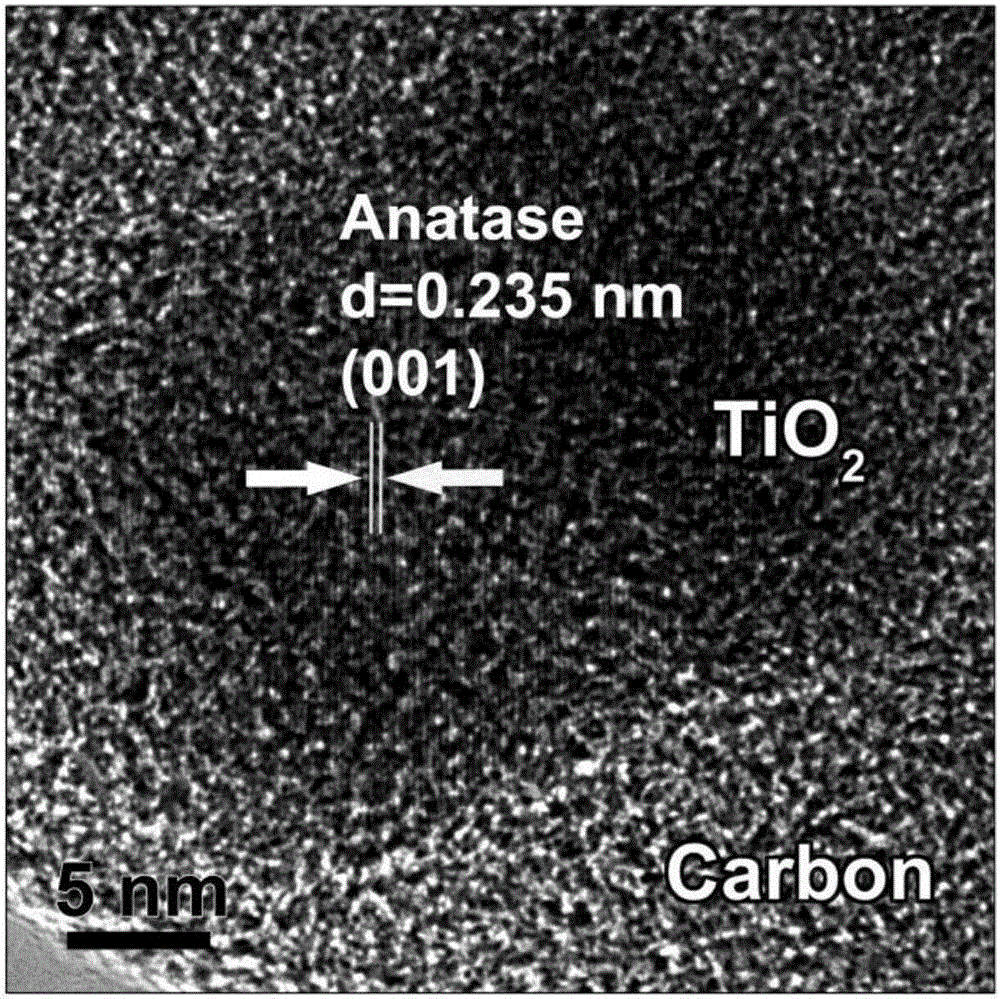

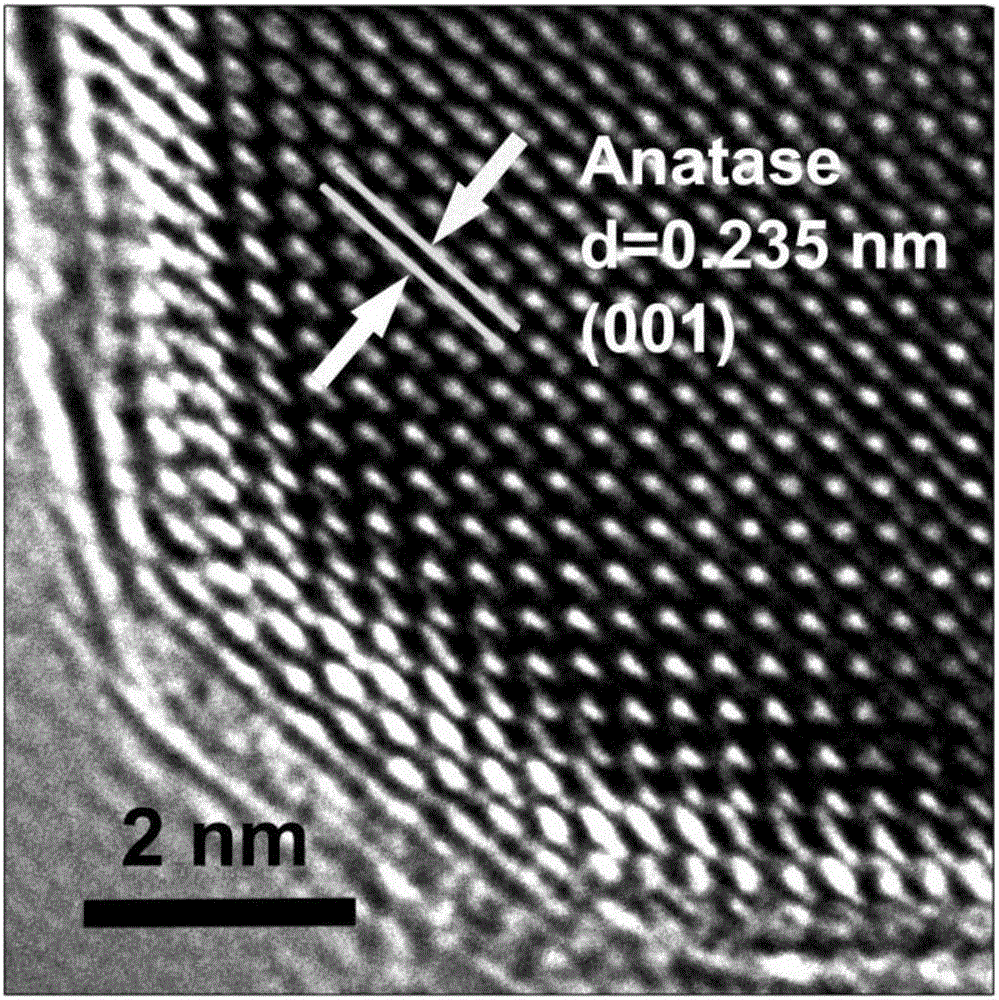

Method for preparing high performance lithium ion battery negative electrode material porous carbon covering exposed (001) active crystal titanium dioxide nanocubes

A technology of lithium-ion batteries and nanocubes, which is applied in nanotechnology for materials and surface science, battery electrodes, nanotechnology, etc., can solve the problems of poor rate performance and cycle stability of lithium-ion batteries, and achieve excellent electrochemical performance , Uniform coating, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for preparing a high-performance lithium-ion battery negative electrode material porous carbon coating exposed (001) active crystal surface titanium dioxide nano-cube, comprising the following steps:

[0031] a. Preparation of phenolic resin spheres

[0032] Add a certain amount of phenol into a mixed solvent of absolute ethanol and deionized water with a certain volume ratio, then add a certain amount of ammonia water, stir for 0.25h at a constant temperature of 25°C, and add a certain amount of deionized water after the phenol is completely dissolved. Hexaalkyltrimethylammonium bromide, continue to stir at a constant temperature of 25°C for 0.5h, then add a certain amount of formaldehyde solution, stir at a constant temperature of 25°C for 24h, transfer the solution to a high-pressure reactor, and conduct water under the condition of 80°C Heat the reaction for 24 hours, cool naturally to room temperature after the reaction, centrifuge, wash, separate and free...

Embodiment 2

[0041] A method for preparing a high-performance lithium-ion battery negative electrode material porous carbon coating exposed (001) active crystal surface titanium dioxide nano-cube, comprising the following steps:

[0042] a. Preparation of phenolic resin spheres

[0043] Add a certain amount of phenol into a mixed solvent of absolute ethanol and deionized water with a certain volume ratio, then add a certain amount of ammonia water, stir for 0.25h at a constant temperature of 25°C, and add a certain amount of deionized water after the phenol is completely dissolved. Hexaalkyltrimethylammonium bromide, continue to stir at a constant temperature of 25°C for 0.5h, then add a certain amount of formaldehyde solution, stir at a constant temperature of 25°C for 24h, transfer the solution to a high-pressure reactor, and conduct water under the condition of 80°C Heat the reaction for 24 hours, cool naturally to room temperature after the reaction, centrifuge, wash, separate and free...

Embodiment 3

[0052] A method for preparing a high-performance lithium-ion battery negative electrode material porous carbon coating exposed (001) active crystal surface titanium dioxide nano-cube, comprising the following steps:

[0053] a. Preparation of phenolic resin spheres

[0054] Add a certain amount of phenol into a mixed solvent of absolute ethanol and deionized water with a certain volume ratio, then add a certain amount of ammonia water, stir for 0.25h at a constant temperature of 25°C, and add a certain amount of deionized water after the phenol is completely dissolved. Hexaalkyltrimethylammonium bromide, continue to stir at a constant temperature of 25°C for 0.5h, then add a certain amount of formaldehyde solution, stir at a constant temperature of 25°C for 24h, transfer the solution to a high-pressure reactor, and conduct water under the condition of 80°C Heat the reaction for 24 hours, cool naturally to room temperature after the reaction, centrifuge, wash, separate and free...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com