A rare earth oxide-doped tungsten-copper alloy composite material and its preparation method

A technology of rare earth oxides and composite materials, which is applied in the preparation of rare earth oxide doped tungsten copper alloy composite materials, and in the field of rare earth oxide doped tungsten copper alloy composite materials, can solve the problem that it is difficult to obtain dense tungsten copper alloy, agglomerated , grain growth and other issues, to achieve the effect of improving compactness, improving sintering performance, toughness and thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The preparation method of the rare earth oxide-doped tungsten-copper alloy composite material of the present invention specifically comprises the following steps:

[0048] 1) Use tungstic acid or soluble tungstate, copper nitrate and rare earth nitrate as raw materials to prepare aqueous solutions respectively, then add an appropriate amount of ammonia water to the copper nitrate solution, and add an appropriate amount of weak acid to the rare earth nitrate solution;

[0049] The add-on of described ammoniacal liquor is: NH 3 The molar ratio to copper nitrate is 2 to 2.5:1, and the concentration of ammonia water used is 15mol L -1 The amount of the organic weak acid added is: the molar ratio of the organic weak acid to the rare earth nitrate is 2 to 3:1; the organic weak acid is added in the form of an acid solution, and the concentration of the organic weak acid in the acid solution is 0.2mol L -1 ;

[0050] The soluble tungstate is one or more of ammonium paratungst...

Embodiment 1

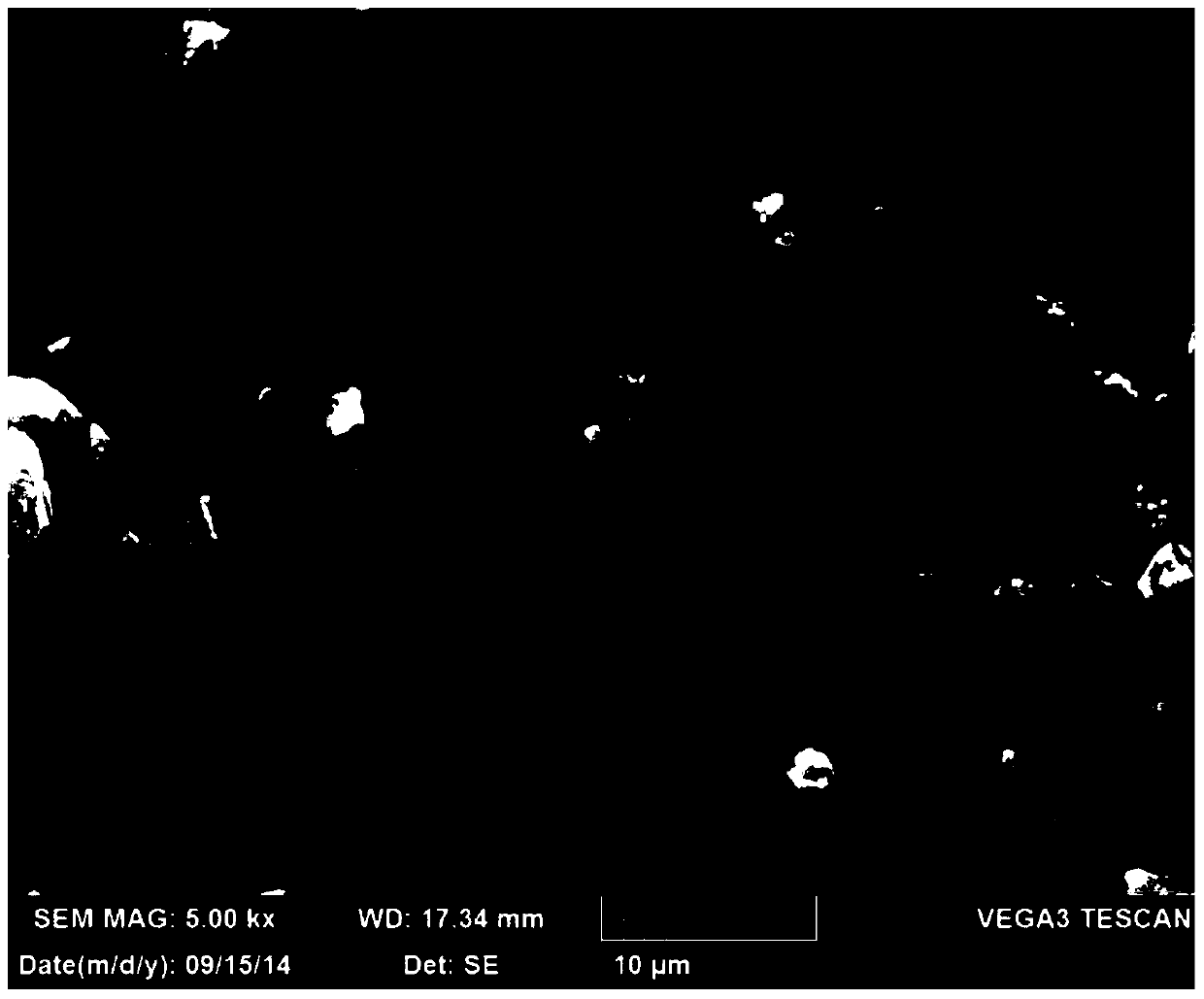

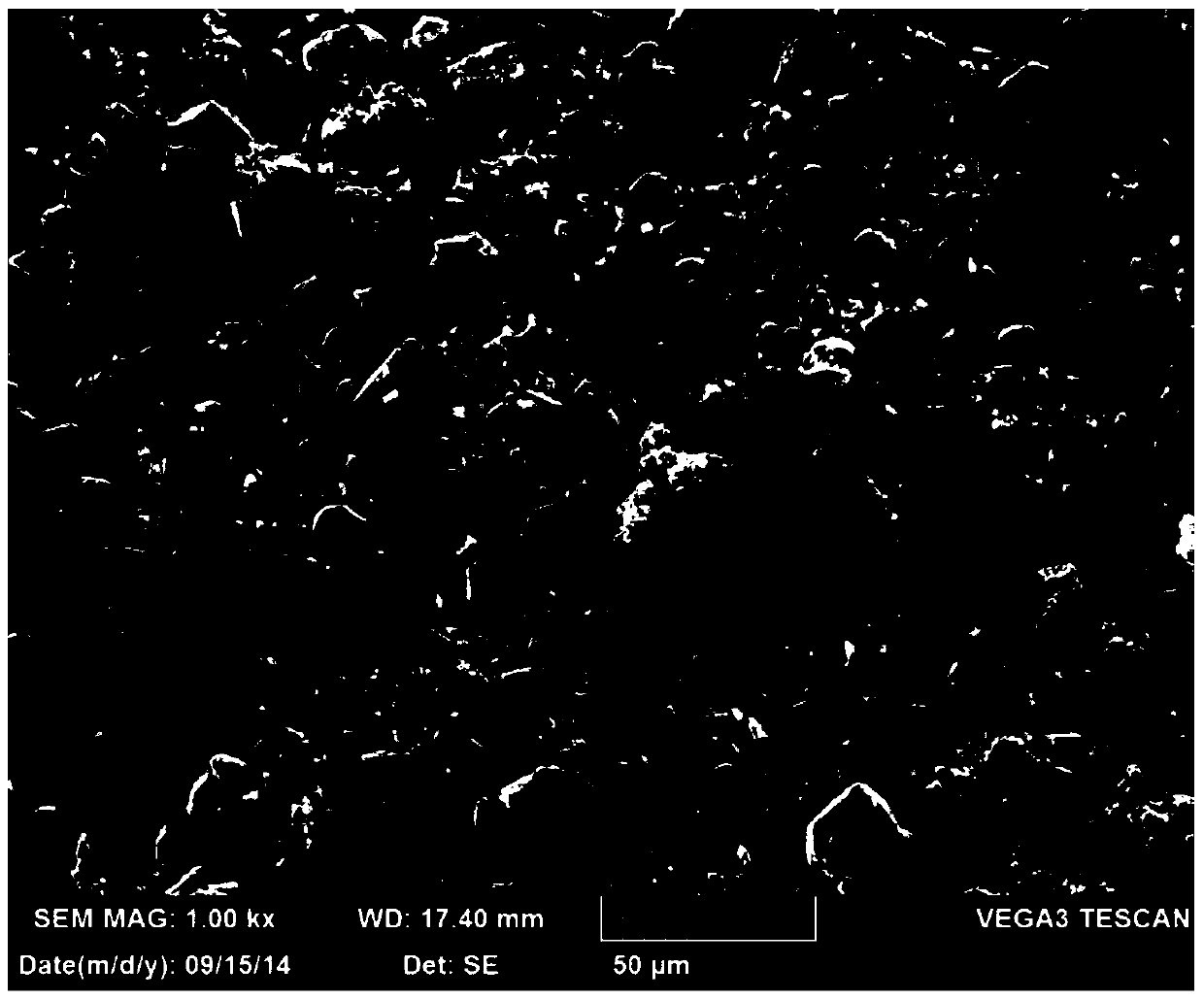

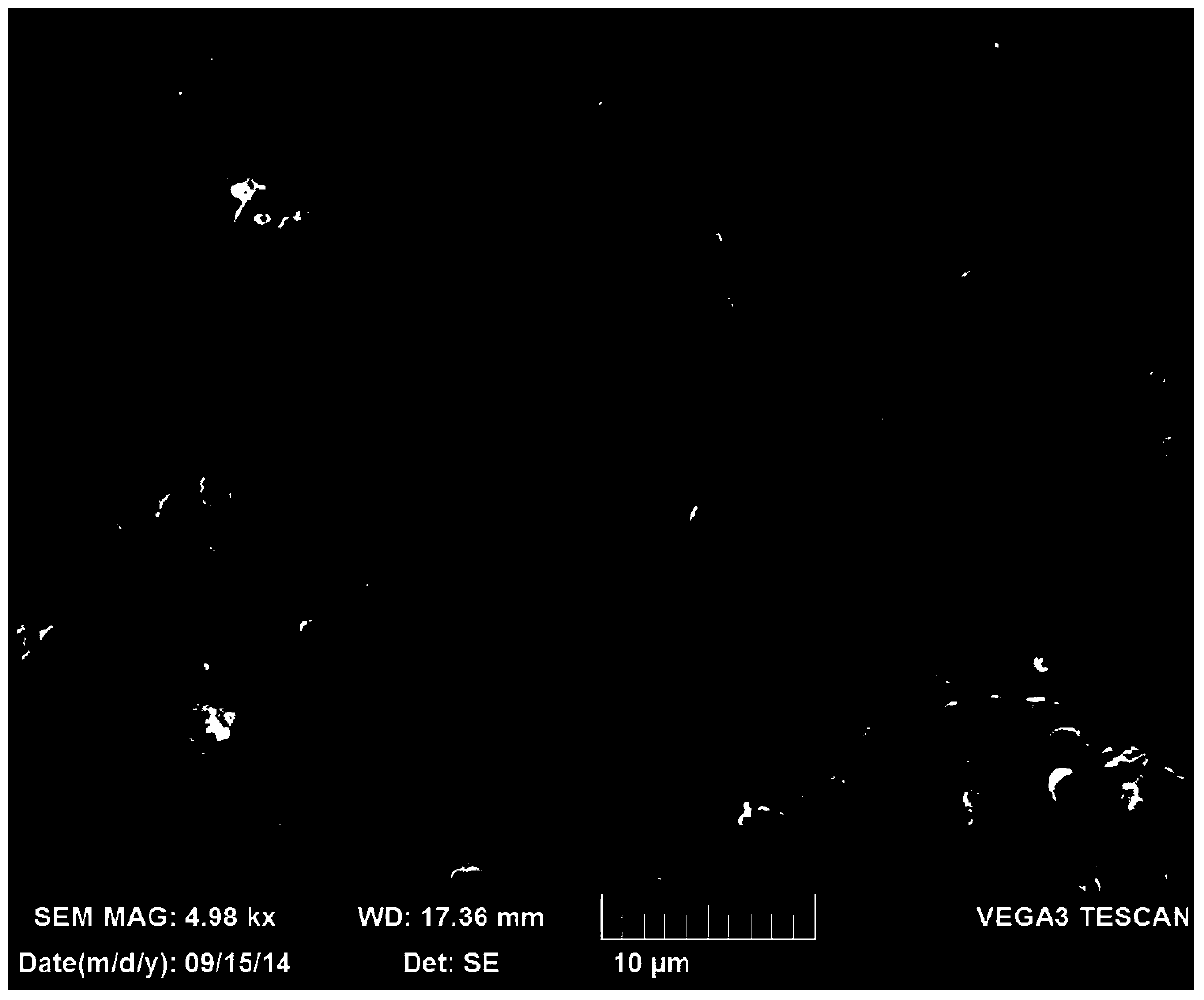

[0058] In the preparation method of the lanthanum oxide-doped tungsten-copper alloy composite material of embodiment 1, the scanning electron microscope picture of the hydrothermal synthesis product obtained in step 3) is as follows figure 1 Shown; Step 4) gained roasting product scanning electron microscope picture is as figure 2 Shown; Step 5) the scanning electron microscope picture of gained lanthanum oxide doped tungsten-copper alloy composite material is as image 3 As shown, the X-ray diffraction spectrum is shown as Figure 4 shown.

[0059] From Figure 1-4 It can be seen that the particle size of the hydrothermal reaction product is fine, the oxidized composite powder is dispersed after roasting, the reduced powder particles are spherical, and the particle size reaches the nanometer level.

Embodiment 6

[0060] In the preparation method of the yttrium oxide-doped tungsten-copper alloy composite material of embodiment 6, the scanning electron microscope image of the hydrothermal synthesis product obtained in step 3) is as follows Figure 5 Shown; Step 4) gained roasting product scanning electron microscope picture is as Figure 6 Shown; Step 5) the scanning electron microscope picture of gained yttrium oxide doped tungsten-copper alloy composite material is as Figure 7 As shown, the EDS energy spectrum is shown as Figure 8 shown.

[0061] From Figure 5-8 It can be seen that the particle size of the hydrothermal reaction product is fine, the oxidized composite powder is dispersed after roasting, the reduced powder particles are spherical, and the particle size reaches the nanometer level.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com