Methane substrate biomembrane reactor and process for removing perchlorate from drinking water

A biofilm reactor, perchlorate technology, applied in waste fuel, anaerobic digestion treatment and other directions, can solve the problems of low methane gas solubility, small mass transfer coefficient, slow growth, etc., to improve methane utilization rate, microorganisms The effect of less loss and less clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

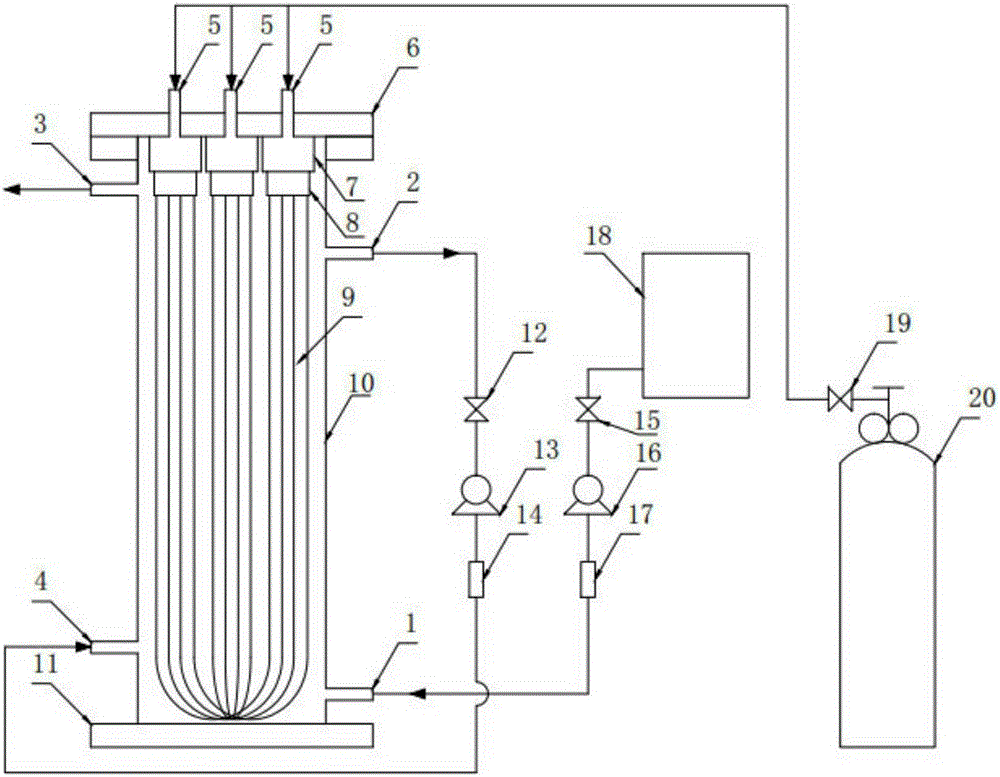

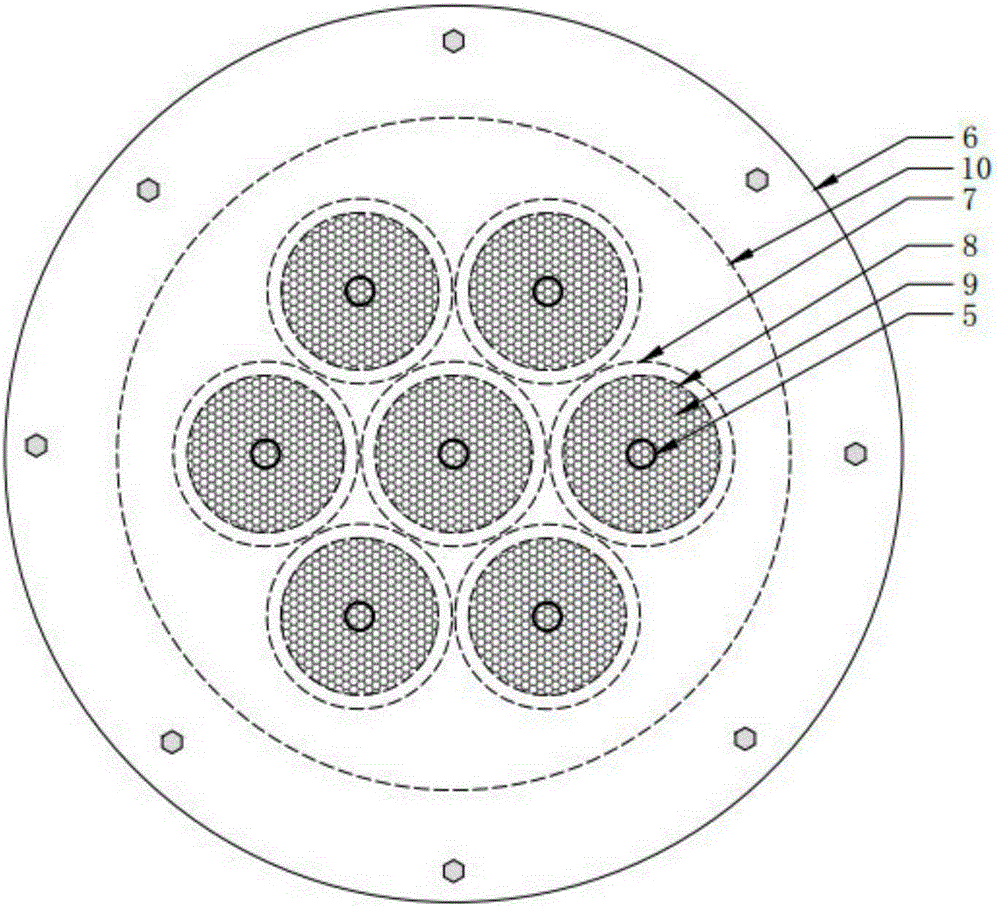

Method used

Image

Examples

Embodiment 1

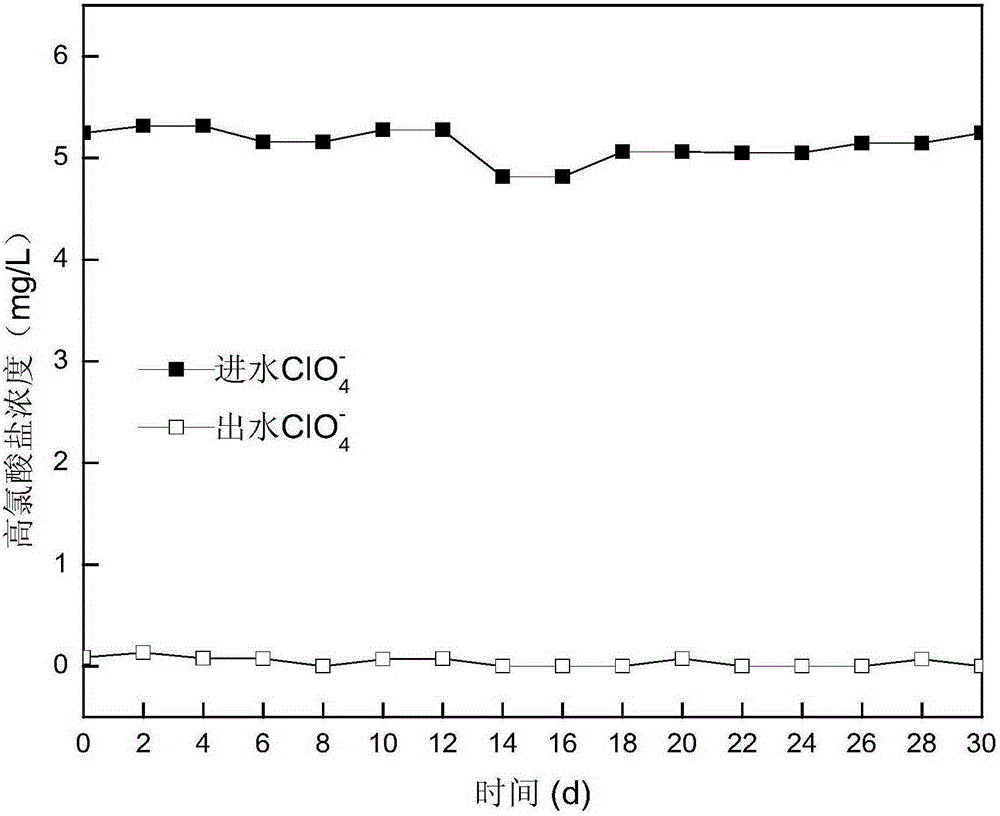

[0042] Treatment Example 1: Control the hydraulic retention time of the methane matrix biofilm reactor to 40 h, and control the internal circulation water flow rate to 100 mL / min. When the influent perchlorate concentration is 5mg / L and the methane gas pressure is 0.04Mpa, the effluent perchlorate concentration is around 0.07mg / L, and the perchlorate removal rate reaches over 98%. like image 3 Shown is the low-concentration perchlorate influent and effluent concentrations in the reactor of the present invention.

Embodiment 2

[0043] Treatment Example 2: Control the hydraulic retention time of the methane matrix biofilm reactor to 40 h, and control the internal circulation water flow rate to 100 mL / min. When the influent perchlorate concentration is 10mg / L and the methane gas pressure is 0.04Mpa, the effluent perchlorate concentration is around 0.20mg / L, and the perchlorate removal rate reaches over 98%. like Figure 4 Shown is a schematic diagram of the concentration of high-concentration perchlorate influent and effluent in the reactor of the present invention.

[0044] As can be seen from the above examples, the methane matrix biofilm reactor provided by the present invention and the removal process of perchlorate in drinking water use the hollow fiber degassing membrane as the carrier for the growth of microorganisms in the system of anaerobic methane oxidation coupled with perchlorate reduction And the supply path of methane gas, methane gas passes through the hollow fiber membrane pores to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com