Preparation of enamel coating modified by rare earth doping and nanometer effect

A technology of enamel and enamel glaze, which is applied in the field of composite materials and can solve the problems of insufficient heat resistance and thermal shock strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

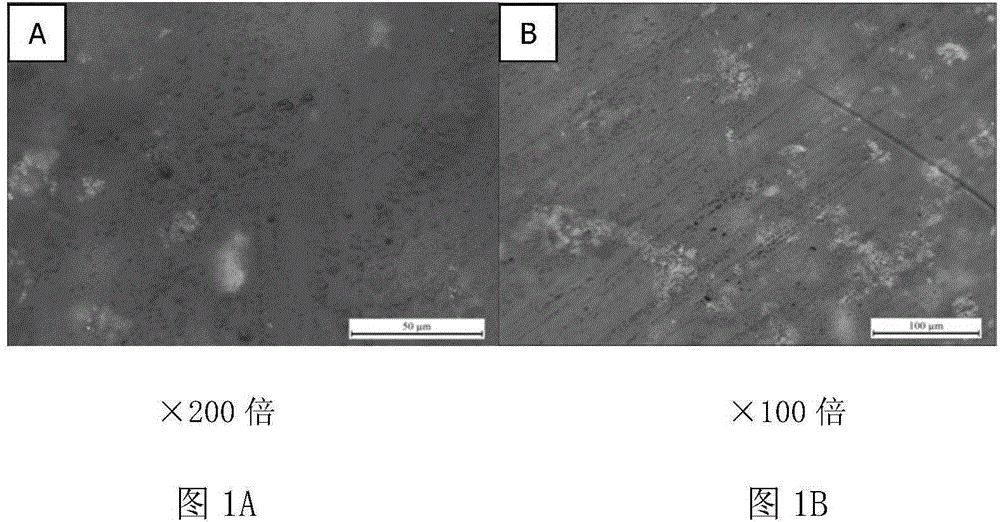

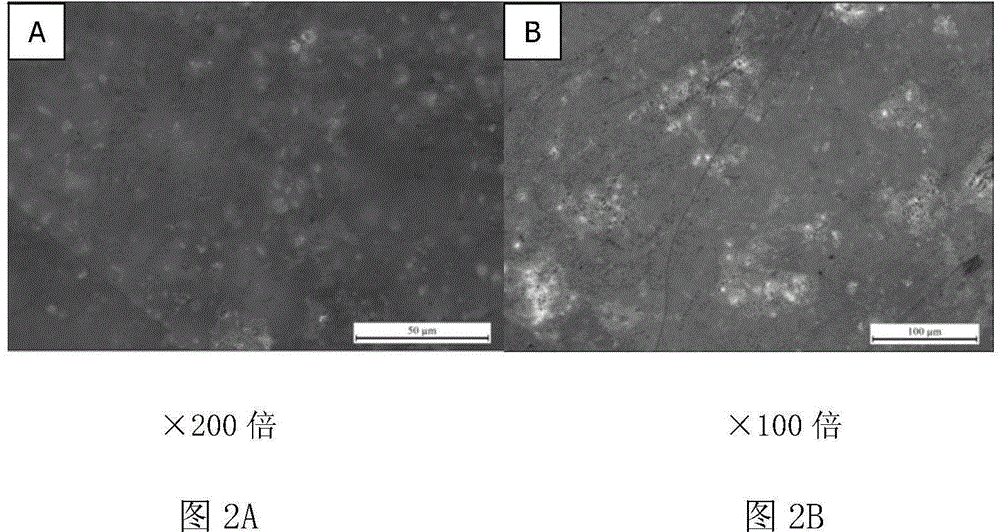

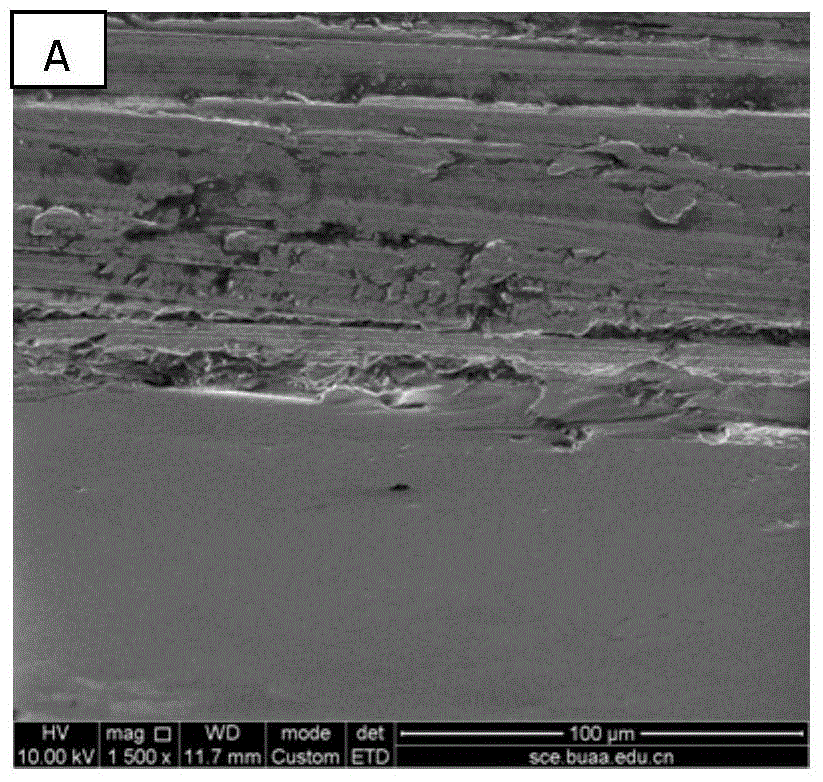

Image

Examples

Embodiment Construction

[0015] According to the present invention, a kind of preparation method of industrial enamel composite material is provided, the method comprises introducing a certain proportion of the mixture of nano-silicon dioxide and rare earth oxide (cerium oxide or lanthanum oxide) into the enamel glaze in the manner of grinding and adding simultaneously , and include the following steps:

[0016] (1) Weighing: Weigh the raw materials and mix them evenly;

[0017] (2) Drying: place the uniformly mixed raw materials in a drying oven at 700-800°C for 1.5 hours (h) to remove moisture and gas from the raw materials;

[0018] (3) High-temperature melting: Put the dried raw materials into the crucible and keep it warm at 1200-1300°C for 1.5h until there are no nodes in the wire drawing;

[0019] (4) quenching: the raw material after melting is dropped into cold water immediately, rapidly cools to room temperature, obtains the frit after quenching, then dry;

[0020] (5) Ball milling pulping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com