Oil-soluble hydroxyapatite nano-sheet preparation method

A technology of hydroxyapatite and nanosheets, which is applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., and can solve the problem that the crystallinity, shape, and uniformity of hydroxyapatite nanocrystals cannot be optimized. In order to achieve the effects of easy implementation, good shape controllability and good dispersibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1) Add 24 mL of 2.08 mol / L calcium nitrate aqueous solution and 48 mL of ethanol, 0.0125 mol oleic acid and 0.0125 mol ethylenediamine into a three-necked flask and mix, and stir to obtain a uniform solution; the molar ratio of soluble calcium salt and soluble phosphate is 5: 3. Under stirring conditions, slowly add 24 mL of triammonium phosphate aqueous solution into the above solution dropwise, and continue stirring for 10 minutes after the addition is completed;

[0036] 2) heating the mixed liquid obtained in step 1) to 80° C. for 6 hours, and then naturally cooling to room temperature to obtain a reaction liquid;

[0037] 3) Use a high-speed centrifuge to centrifuge the reaction solution obtained in step 2) to obtain a precipitate, and use absolute ethanol and cyclohexane to alternately centrifuge and wash 3 times to remove electrolytes and excess fatty acids in the system to obtain oil-soluble hydroxyapatite nanosheets .

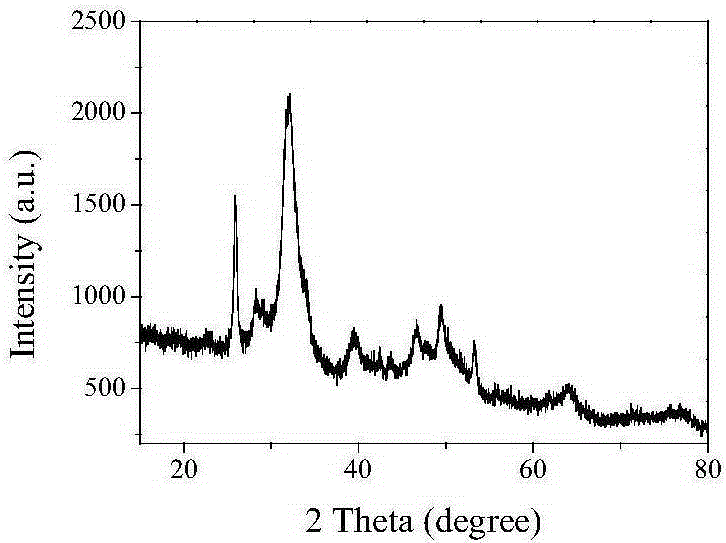

[0038] The X-ray diffraction pattern of ...

Embodiment 2

[0040] 1) Add 24 mL of 2.08 mol / L calcium nitrate aqueous solution and 48 mL of ethanol, 0.025 mol of oleic acid and 0.025 mol of ethylenediamine into a three-necked flask and mix, and stir to obtain a uniform solution; the molar ratio of soluble calcium salt and soluble phosphate is 5: 3. Under stirring conditions, slowly add 24 mL of diammonium hydrogen phosphate aqueous solution to the above solution dropwise, and continue stirring for 10 minutes after the addition is completed;

[0041] 2) heating the mixed liquid obtained in step 1) to 80° C. for 3 hours and then cooling it to room temperature naturally to obtain a reaction liquid;

[0042] 3) Use a high-speed centrifuge to centrifuge the reaction solution obtained in step 2) to obtain a precipitate, and use absolute ethanol and cyclohexane to alternately centrifuge and wash 3 times to remove electrolytes and excess fatty acids in the system to obtain oil-soluble hydroxyapatite nanosheets .

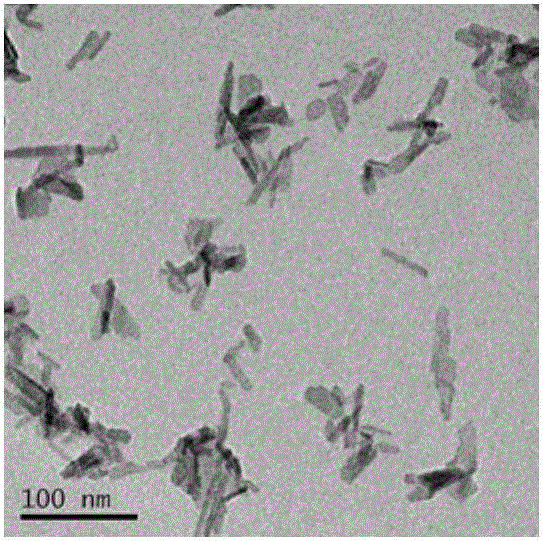

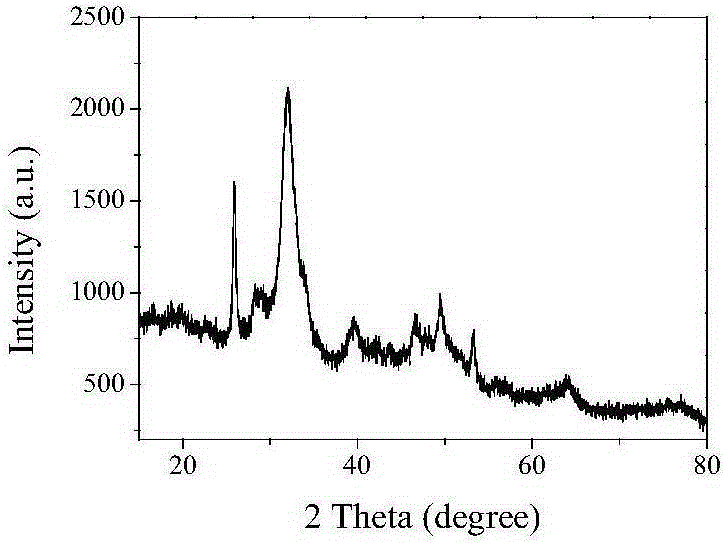

[0043] The X-ray diffraction...

Embodiment 3

[0045] 1) Add 24 mL of 2.08 mol / L calcium chloride aqueous solution, 24 mL of propanol and 24 mL of ethanol, 0.0375 mol of oleic acid and 0.0375 mol of ethylenediamine into a three-necked flask and mix, and stir to obtain a uniform solution; soluble calcium salt and soluble phosphate The molar ratio is 5:3. Under stirring conditions, 24 mL of ammonium dihydrogen phosphate aqueous solution is slowly added dropwise to the above solution, and the stirring is continued for 10 minutes after the addition is completed;

[0046] 2) heating the mixed solution obtained in step 1) to 80° C. for 12 hours, and then naturally cooling to room temperature to obtain a reaction solution;

[0047] 3) Use a high-speed centrifuge to centrifuge the reaction solution obtained in step 2) to obtain a precipitate, and use absolute ethanol and cyclohexane to alternately centrifuge and wash 3 times to remove electrolytes and excess fatty acids in the system to obtain oil-soluble hydroxyapatite nanosheets ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average width | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

| Average width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com