Micropore EPDM foamed material with excellent compression resilience performance and preparation method

A technology of EPDM rubber and foam materials, applied in the field of foam materials, can solve the problems of large relaxation and creep of foam materials, poor compression resilience, poor recovery and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

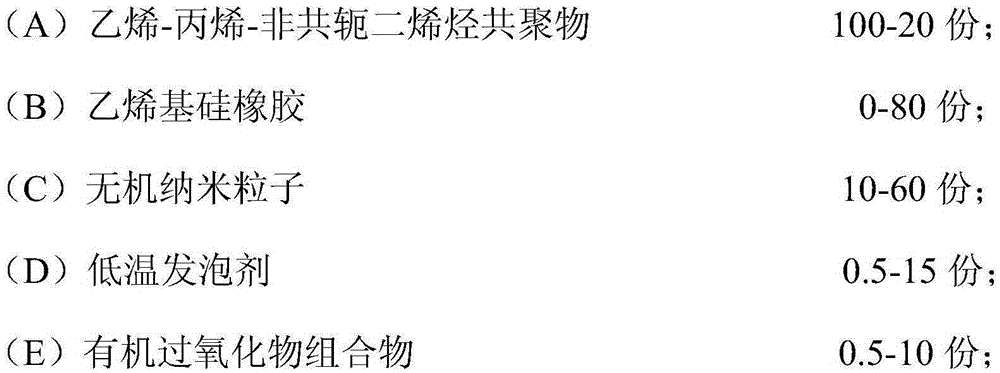

Method used

Image

Examples

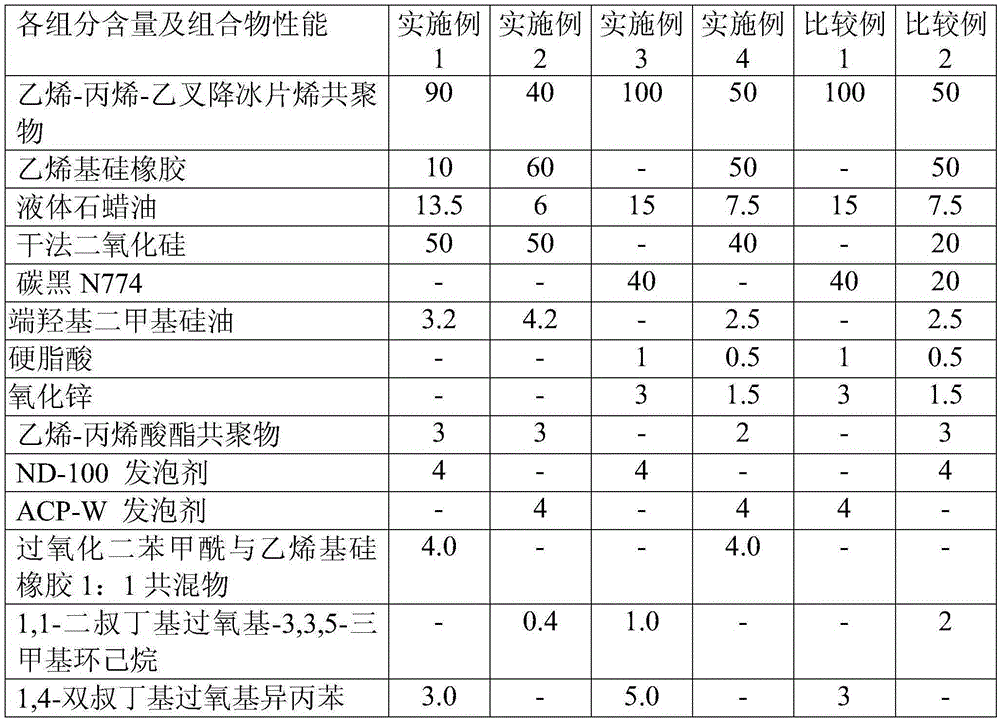

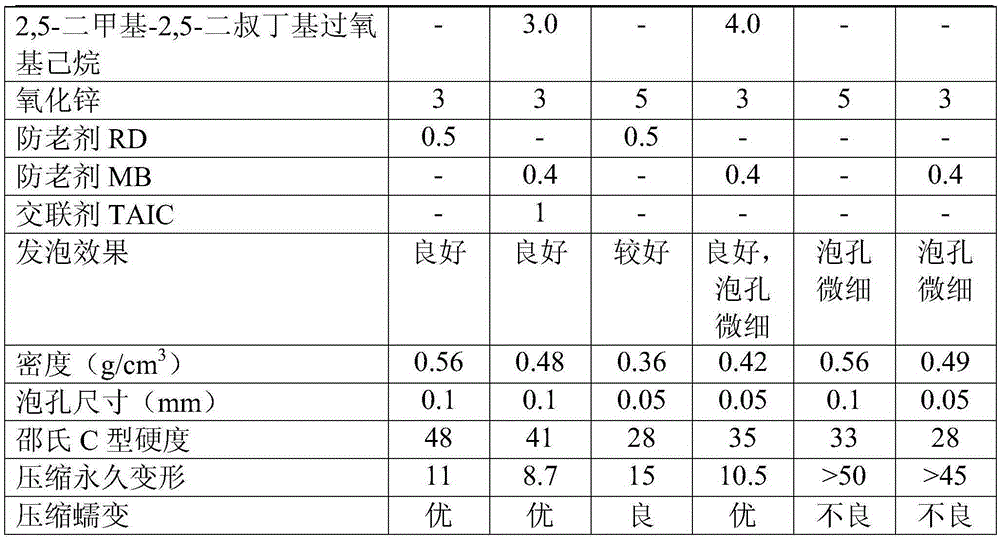

Embodiment 1

[0073] 100 parts of ethylene-propylene-ethylidene norbornene copolymer (brand name MITSUI4045, Mooney viscosity 45, iodine value 23), 50 parts BET specific surface area is 195m 2 Dry-process silica AS-200 (trade name, manufactured by Shenyang Chemical Co., Ltd.) per g, 15 parts of liquid paraffin oil and 3 parts containing silanol groups at both ends and having a viscosity of 29 mm 2 / s (23°C) dimethyl polysiloxane was added to a 5L internal mixer, heated and internally kneaded at 80°C for 30 minutes, and the discharged material was cooled to room temperature to obtain EPDM rubber reinforcing base material.

[0074] 100 parts containing 90.825 mol % of dimethyl siloxane unit, 0.15 mol % of methyl vinyl siloxane unit, 10.0 mol % of methylphenyl siloxane unit, 0.025 mol % of dimethyl vinyl siloxane unit % of organopolysiloxane with an average degree of polymerization of 8000, 50 parts of BET surface area of 200m 2 / g of fumed silica AS-200, 5 parts have silanol groups at bo...

Embodiment 2

[0085] Prepare EPDM rubber reinforcing base material and vinyl silicone rubber reinforcing base material in the same manner as in Example 1; and 51 parts of EPDM rubber reinforcing base material and 108.5 parts by mass of vinyl silicone rubber reinforcing material The base material and 3 parts of ethylene-acrylate copolymer (VamacDP, DuPont, USA) were mixed in an internal mixer at 150° C. for 20 minutes, and the base material of the EPDM rubber composition was obtained after uniform mixing.

[0086] Add in 162.5 parts of EPDM composition base material prepared in this way:

[0087] 5 parts of ACP-W foaming agent (Hangzhou Haihong Fine Chemical Co., Ltd., a mixture of N,N-dinitrosopentamethylenetetramine, azodicarbonamide and foaming aids, with an average particle size of 9- 14 microns, outgassing volume 125-135ml / g, initial thermal decomposition temperature 125-133℃);

[0088] 0.4 parts of 1,1-di-tert-butylperoxy-3,3,5-trimethylcyclohexane (purity 95%) as component E1;

[00...

Embodiment 3

[0095] In addition to not using component (B), component A is 100 parts by mass, component (C) is changed to 40 parts of carbon black 774, silicone oil is changed to 1.0 parts of stearic acid, and 3 parts of zinc oxide. In addition, the organic peroxide E1 is adjusted from dibenzoyl peroxide to 1 part of 1,1-di-tert-butylperoxy-3,3,5-trimethylcyclohexane, and E2 is 1 part of 1,4-di-tert-butylperoxy The amount of cumene was adjusted to 5 parts and the blending process and the ethylene acrylate copolymer were omitted, and the EPDM foam material was prepared in the same manner as in Example 1, and its physical and mechanical property data are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| iodine value | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com