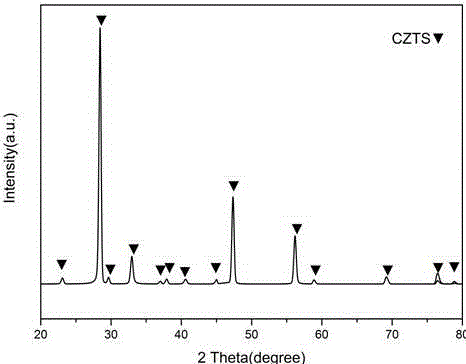

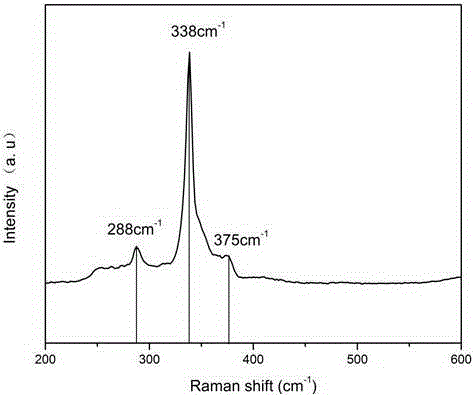

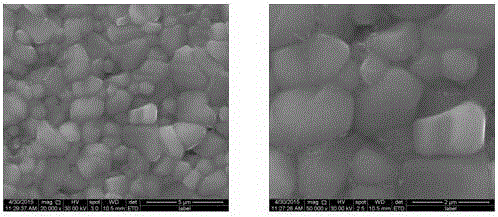

Method for preparing CZTS thin film solar cell based on full vacuum method

A thin-film solar cell, copper-zinc-tin-sulfur technology, applied in the manufacture of circuits, electrical components, final products, etc., can solve the problems of highly volatile and toxic ammonia water, affecting the performance of the buffer layer, and being unfriendly to the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Substrate cleaning: The soda-lime glass is ultrasonically cleaned with acetone, alcohol, and deionized water in sequence, and dried with nitrogen for later use;

[0026] (2) Put the cleaned soda-lime glass into the magnetron sputtering system and heat it up to 150°C for 30 minutes, and use a molybdenum target with a size of 76.2mm*3mm as the target for DC sputtering, and the background vacuum is 5.0* 10 -4 pa, the substrate temperature is 160°C, the ignition pressure is 1.6pa, and the power is 150W. Sputter for 15 minutes when the argon gas is 1.6pa, then adjust the argon gas to 0.3pa and sputter for 105 minutes. Operate on soda-lime glass according to the above requirements Obtain a 1 μm molybdenum back electrode film on the surface, and then heat up to 220 and bake for 30 minutes;

[0027] (3) Preparation of copper-zinc-tin-sulfur thin film pre-layer: use ZnS, Sn and CuS with a size of 76.2mm*3mm as targets, perform radio frequency sputtering in the order of SLG / ...

Embodiment 2

[0032] (1) Substrate cleaning: The soda-lime glass is ultrasonically cleaned with acetone, alcohol, and deionized water in sequence, and dried with nitrogen for later use;

[0033] (2) Put the cleaned soda-lime glass into the magnetron sputtering system and heat it up to 150°C for 30 minutes, and use a molybdenum target with a size of 76.2mm*3mm as the target for DC sputtering, and the background vacuum is 5.0* 10 -4 pa, the substrate temperature is 160°C, the ignition pressure is 1.6pa, and the power is 150W. Sputter for 15 minutes when the argon gas is 1.6pa, then adjust the argon gas to 0.3pa and sputter for 105 minutes. Operate on soda-lime glass according to the above requirements Obtain a 1 μm molybdenum back electrode film on the surface, and then heat up to 220 and bake for 30 minutes;

[0034] (3) Preparation of copper-zinc-tin-sulfur thin film pre-layer: use ZnS, Sn and CuS with a size of 76.2mm*3mm as targets, perform radio frequency sputtering in the order of SLG / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com