Crosslinking type positively-charged chlorine-containing polymer filter membrane and preparation method thereof

A polymer, positively charged technology, used in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., to improve performance, reduce membrane production steps, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0108] The invention relates to a preparation method of a cross-linked positively charged chlorine-containing polymer filter membrane, which is characterized in that it comprises the following steps:

[0109] (1) dissolving the first chlorine-containing polymer in a solvent, and carrying out graft polymerization of tertiary amine monomers through in-situ atom transfer radical polymerization to obtain the second chlorine-containing polymer solution;

[0110] (2) The second chlorine-containing polymer solution obtained in step (1) is directly used as a film-making solution through non-solvent-induced phase separation to form a solid precursor film;

[0111] or,

[0112] (2) the second chlorine-containing polymer solution obtained in step (1), adding the first chlorine-containing polymer and stirring to form a uniform film-making solution, and forming a solid precursor film through non-solvent-induced phase separation;

[0113] (3) heat-treating the solid precursor membrane to o...

Embodiment 1

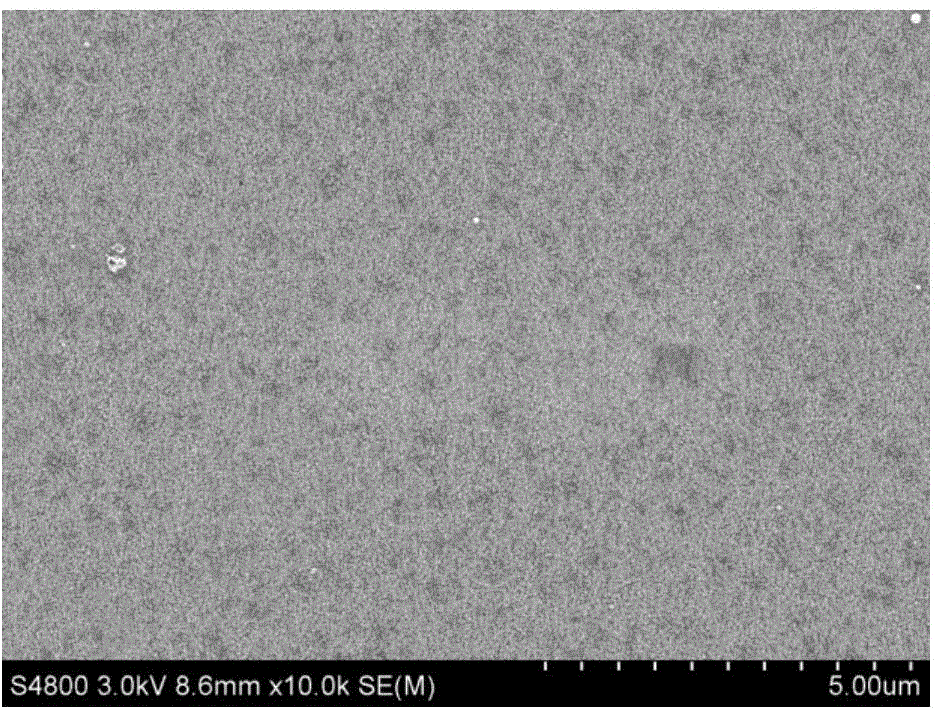

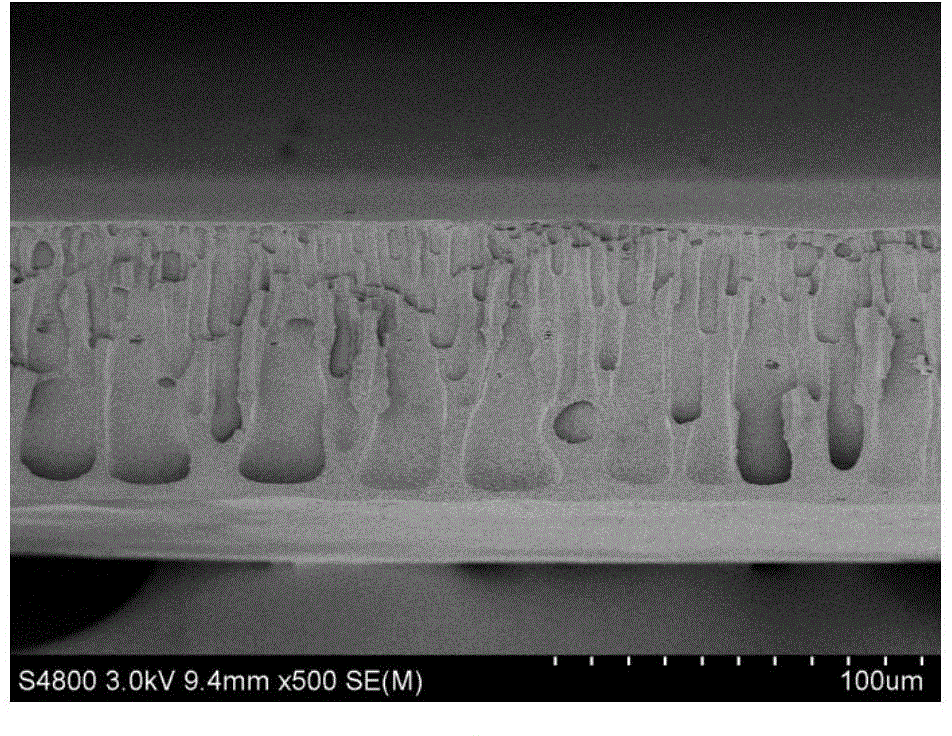

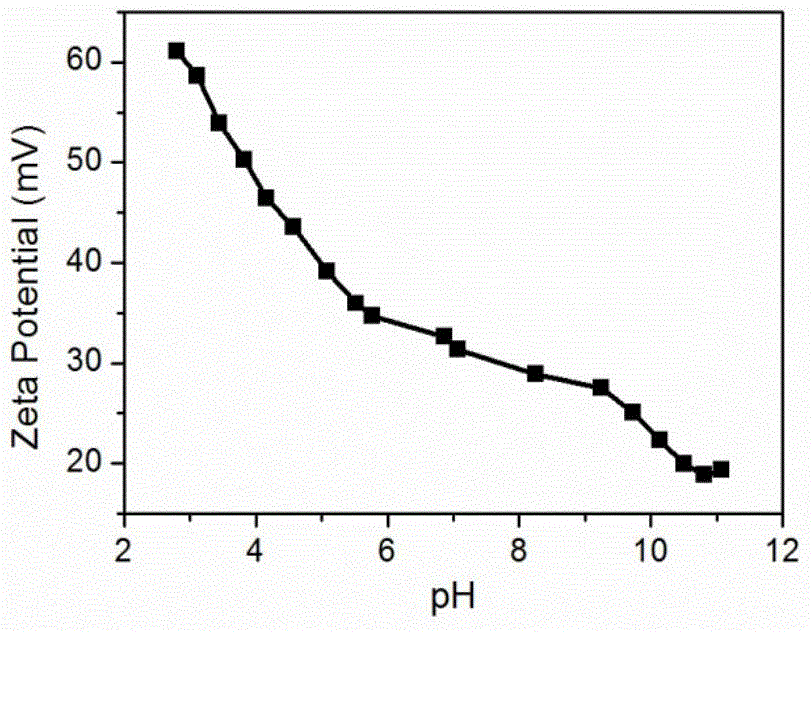

[0135] 1) Forming a chlorine-containing polymer film-making solution by in-situ atom transfer radical polymerization. Dissolve 10g of polyvinyl chloride (the first chlorine-containing polymer) in 85g of N'N-dimethylacetamide at room temperature, feed nitrogen into the solution for 30 minutes to remove oxygen in the solution, and then add 15.0 g dimethylaminoethyl methacrylate, 44.1 mg pentamethyldiethylenetriamine and 25.2 mg cuprous chloride, and then the reaction solution was placed at 65° C. for 12 hours. After the reaction is finished, air is introduced into the system to terminate the reaction to form the second chlorine-containing polymer solution. 2) In the stirring state, continue to add 5 g of polyvinyl chloride, 5 g of polyethylene glycol and 0.5 g of polyvinyl pyrrolidone into the solution, and stir at 60° C. for 24 hours. Additives polyethylene glycol, molecular weight 200 g / mol, polyvinylpyrrolidone, molecular weight 30,000 g / mol. Spread the above film-making so...

Embodiment 2

[0163] 1) Same as Step 1 of Example 1. 2) Coat the above-mentioned film-making solution on the non-woven fabric, immerse in water at 30°C to solidify to form a solid precursor film with support, and then soak the film in water to remove soluble substances such as solvents. Small molecule. 3) After drying the formed solid film, heat treatment is carried out at a temperature of 120° C. and a treatment time of 2 hours to obtain a cross-linked positively charged chlorine-containing polymer composite filter membrane

[0164] Test results and discussion: 1) Solubility test results are shown in Table 1, showing that after heat treatment of chlorine-containing polymer filter membranes, the filter membrane solvent resistance (DMF, DMAc and NMP) ability is greatly enhanced; 2) Membrane filtration separation performance test results are as follows: Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com