Water-reducing slump-retaining type polycarboxylic acid water reducing agent and preparing method thereof

A technology of polycarboxylic acid and water reducing agent, which is applied in the field of building materials, can solve the problems of high cost setting time and strength, large slump loss, and long production cycle, so as to improve the competitive adsorption capacity, increase the copolymerization ratio, reduce The effect of self-aggregation ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

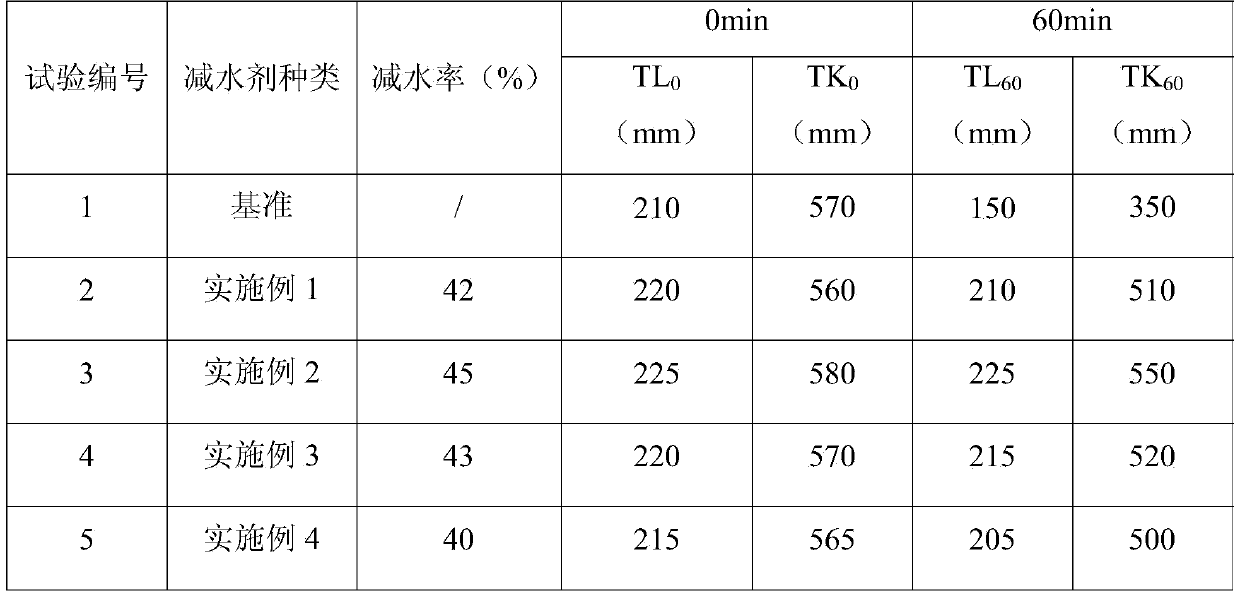

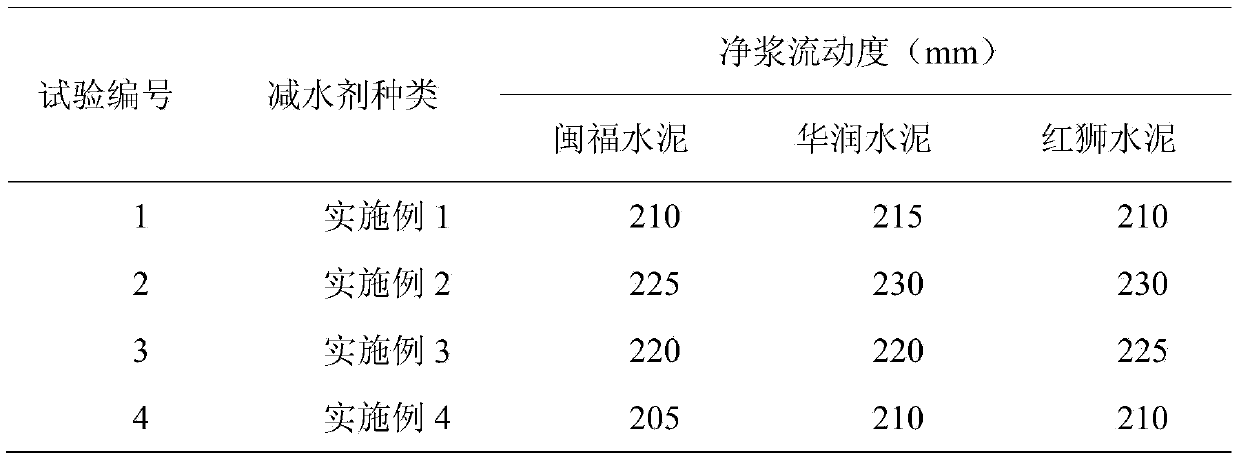

Examples

Embodiment 1

[0028] (1) Weigh each raw material component according to the following parts by weight: 200 parts of isopentenol polyoxyethylene ether with a molecular weight of 2400, 19 parts of acrylic acid, 3 parts of hydroxyethyl acrylate, 2-methacryloyloxyethyl 1 part of phosphoric acid ester, 2 parts of vinyl glycol ether, 2 parts of hydrogen peroxide, 0.5 part of ascorbic acid, 0.2 part of sodium bisulfite formaldehyde, 1.2 parts of thioglycolic acid, 325 parts of water and 15 parts of 32% mass concentration liquid caustic soda;

[0029] (2) Acrylic acid, hydroxyethyl acrylate, 2-methacryloxyethyl phosphate and vinyl glycol ether are dissolved in 30 parts by weight of water to obtain the first solution, and ascorbic acid and thioglycolic acid are dissolved in 30 parts by weight Parts of water to get the second solution, sodium bisulfoxylate formaldehyde is dissolved in 30 parts by weight of water to get the third solution;

[0030] (3) Mix prenyl alcohol polyoxyethylene ether with a m...

Embodiment 2

[0033] (1) Weigh each raw material component according to the following parts by weight: 200 parts of isopentenol polyoxyethylene ether with a molecular weight of 2400, 20 parts of acrylic acid, 2.5 parts of hydroxyethyl methacrylate, 2-methacryloyloxy 1.2 parts of ethyl phosphate, 2.5 parts of 4-hydroxybutyl vinyl ether, 2.2 parts of sodium persulfate, 0.4 parts of sodium hypophosphite, 0.3 parts of sodium bisulfite formaldehyde, 1.0 parts of mercaptopropionic acid, 325 parts of water and 32% 16 parts of mass concentration liquid caustic soda;

[0034] (2) Acrylic acid, hydroxyethyl methacrylate, 2-methacryloyloxyethyl phosphate and 4-hydroxybutyl vinyl ether are dissolved in 30 parts by weight of water to obtain the first solution, and sodium hypophosphite and Mercaptopropionic acid is dissolved in 30 parts by weight of water to obtain the second solution, and sodium bisulfoxylate formaldehyde is dissolved in 30 parts by weight of water to obtain the third solution;

[0035...

Embodiment 3

[0038] (1) Weigh each raw material component according to the following parts by weight: 200 parts of isopentenol polyoxyethylene ether with a molecular weight of 2400, 20 parts of acrylic acid, 3 parts of hydroxyethyl acrylate, 2-methacryloxypropyl 1.1 parts of phosphoric acid ester, 2.2 parts of 4-hydroxybutyl vinyl ether, 3.0 parts of ammonium persulfate, 0.5 parts of sodium hypophosphite, 0.2 parts of sodium bisulfite formaldehyde, 1.0 parts of mercaptopropionic acid, 325 parts of water and 32% mass concentration 16 parts of liquid caustic soda;

[0039] (2) Acrylic acid, hydroxyethyl acrylate, 2-methacryloxypropyl phosphate and 4-hydroxybutyl vinyl ether are dissolved in 30 parts by weight of water to obtain the first solution, and sodium hypophosphite and mercaptopropyl The acid is dissolved in 30 parts by weight of water to obtain the second solution, and sodium bisulfoxylate formaldehyde is dissolved in 30 parts by weight of water to obtain the third solution;

[0040...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com