Fabrication method of PEDOT:PSS-coated nano MnO<2>-based graphene nano wall electrode

A technology of graphene nano-wall and manufacturing method, which is applied in the direction of nanotechnology, nanotechnology, hybrid capacitor electrodes, etc., can solve the problems of limited surface area improvement, poor graphene wall structure, small effective surface area, etc., and achieve good dispersion and improved Scatter, avoid the effect of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

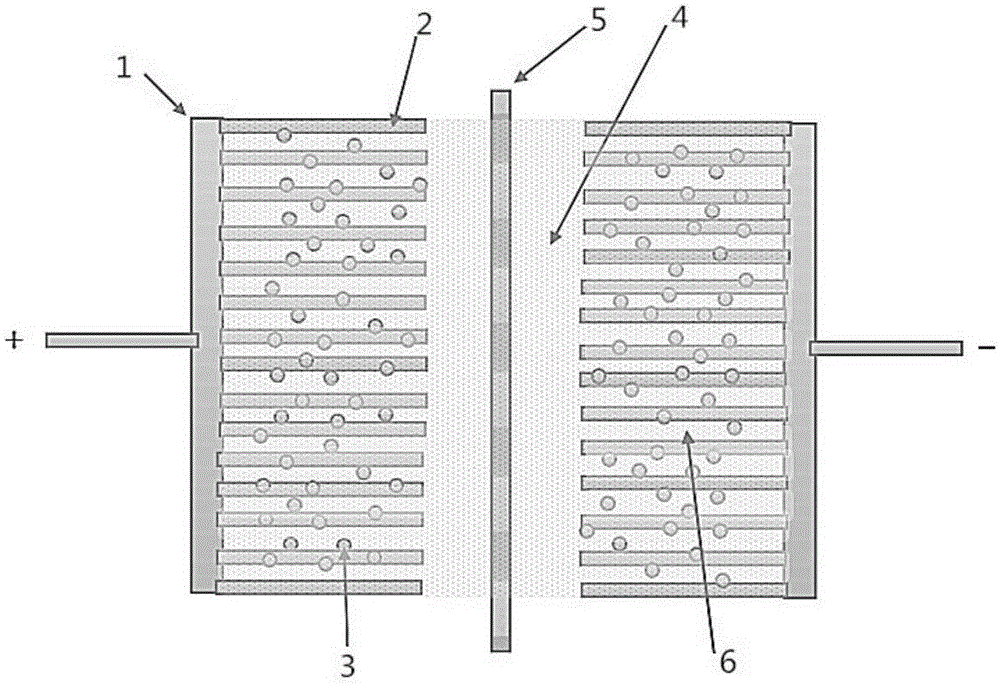

[0036] Copper sheet is used as substrate 1, and graphene nanowall 2 is prepared by PECVD; nano-MnO coated with PEDOT:PSS (mass ratio 1:1) is prepared using manganese chloride as a precursor 2 Particle graphene nano-wall supercapacitor electrode, specific structure see figure 1 .

[0037] in CH 4 The plasma was used as a precursor, and Cu was heated to 800 °C in a PECVD reactor by passing argon and hydrogen at the same time. The graphene nano-wall 2 is grown on the substrate 1 by the PECVD method, and the growth time is controlled to be 30 minutes, so that the graphene nano-wall 2 with a height of 1 micron can be obtained. to N 2 The plasma was bombarded at 50W for 100s. Manganese chloride is used as a precursor and dissolved in water or ethanol. Add 1 part by mass of manganese chloride to the solution and stir thoroughly at 50°C to obtain a 0.5 mol / L manganese chloride solution. Add the citric acid of 5 mass parts in the manganese chloride solution that obtains as chelat...

Embodiment 2

[0040] Using metal nickel as the substrate, using PECVD to prepare graphene nanowalls; using manganese chloride as a precursor to prepare nano-MnO coated with PEDOT:PSS (mass ratio 1:2) 2 Granular graphene nanowall electrodes.

[0041] in CH 4 The plasma of Ni was used as a precursor, and Ni was heated to 800 °C in a PECVD reactor. The graphene nanowall is grown on the substrate by PECVD method, and the growth time is controlled to 60 minutes, and the graphene nanowall with a height of 3 microns can be obtained. with O 2 The plasma was bombarded for 210s at 60W power. Manganese chloride is used as a precursor and dissolved in water or ethanol. Add 5 parts by mass of manganese chloride to the solution, and stir thoroughly at 50°C to obtain a 0.5 mol / L manganese chloride solution. Add the tartaric acid of 10 mass parts in the manganese chloride solution that obtains as chelating agent. Concentrated hydrochloric acid was added dropwise to adjust the pH to 3. Then add 2-10 ...

Embodiment 3

[0043] Using silicon wafers as substrates, PECVD is used to prepare graphene nanowalls; manganese chloride is used as a precursor to prepare nano-MnO coated with PEDOT:PSS (1:0.5) 2 Granular graphene nanowall electrodes.

[0044] in CH 4 Plasma is used as a precursor, and the Si wafer is heated to 1000°C in a PECVD reactor. The graphene nanowall is grown on the substrate by PECVD method, and the growth time is controlled to be 150 minutes, and the graphene nanowall with a height of 5 microns can be obtained. Take NH 3 The plasma was bombarded at 100W for 165s. Manganese chloride is used as a precursor and dissolved in water or ethanol. Add 2 parts by mass of manganese chloride to the solution, and stir well at 50°C. Obtain 0.2mol / L manganese chloride solution. Add 4 parts by mass of citric acid to the obtained manganese chloride solution, tartaric acid is used as a chelating agent, and concentrated hydrochloric acid is added dropwise to adjust the pH to 3. Add 2-10 mass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com