Efficient industrial sewage treating agent and preparation method thereof

A technology of industrial sewage and treatment agent, which is applied in water/sewage treatment, water/sludge/sewage treatment, polluted waterways/lakes/ponds/rivers treatment, etc. It can solve the problems of container corrosion damage and damage to water quality, etc. Achieve the effect of fast purification speed and easy use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

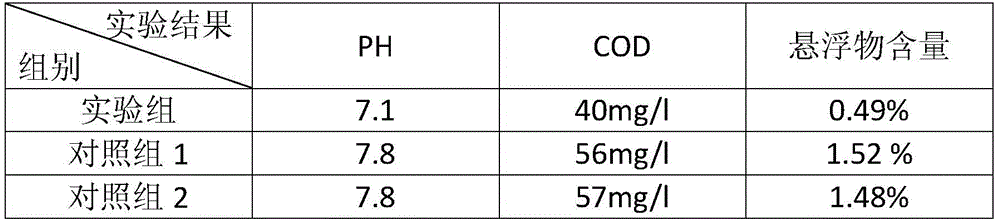

Examples

Embodiment 1

[0021] A high-efficiency industrial sewage treatment agent, the raw materials are composed of the following parts by weight: 20 parts of corn starch, 20 parts of alum, 18 parts of potassium persulfate, 12 parts of sodium lignosulfonate, 16 parts of magnesium oxide, and 18 parts of sodium hypochlorite 18 parts of polyferric chloride, 12 parts of calcium hydroxide, 20 parts of sodium silicate, 12 parts of sodium chloride, 18 parts of sepiolite, 18 parts of acetic acid, 16 parts of titanium dioxide, 22 parts of zinc oxide and ammonium persulfate 18 servings.

[0022] A preparation method of an efficient industrial sewage treatment agent, comprising the following steps:

[0023] 1) Take 20 parts of corn starch, 20 parts of alum, 18 parts of potassium persulfate, 12 parts of sodium lignosulfonate and 16 parts of magnesium oxide, put them into a blender, add 1.5 times of water, stir evenly, and set aside;

[0024] 2) Take 18 parts of sodium hypochlorite, 18 parts of polyferric tric...

Embodiment 2

[0031] A high-efficiency industrial sewage treatment agent, the raw materials are composed of the following parts by weight: 21 parts of corn starch, 19 parts of alum, 17 parts of potassium persulfate, 11 parts of sodium lignosulfonate, 14 parts of magnesium oxide, 15 parts of sodium hypochlorite 14 parts of polyferric chloride, 11 parts of calcium hydroxide, 18 parts of sodium silicate, 10 parts of sodium chloride, 15 parts of sepiolite, 17 parts of acetic acid, 14 parts of titanium dioxide, 20 parts of zinc oxide and ammonium persulfate 17 servings.

[0032] A preparation method of an efficient industrial sewage treatment agent, comprising the following steps:

[0033] 1) Take 21 parts of corn starch, 19 parts of alum, 17 parts of potassium persulfate, 11 parts of sodium lignosulfonate and 14 parts of magnesium oxide, put them into a blender, add 1.5 times of water, stir evenly, and set aside;

[0034] 2) Take 15 parts of sodium hypochlorite, 14 parts of polyferric trichlor...

Embodiment 3

[0041] A high-efficiency industrial sewage treatment agent, the raw materials are composed of the following parts by weight: 22 parts of corn starch, 18 parts of alum, 16 parts of potassium persulfate, 10 parts of sodium lignosulfonate, 12 parts of magnesium oxide, 12 parts of sodium hypochlorite 10 parts of polyferric chloride, 10 parts of calcium hydroxide, 16 parts of sodium silicate, 8 parts of sodium chloride, 12 parts of sepiolite, 16 parts of acetic acid, 12 parts of titanium dioxide, 18 parts of zinc oxide and ammonium persulfate 16 servings.

[0042] A preparation method of an efficient industrial sewage treatment agent, comprising the following steps:

[0043] 1) Take 22 parts of cornstarch, 18 parts of alum, 16 parts of potassium persulfate, 10 parts of sodium lignosulfonate and 12 parts of magnesium oxide, put them into a blender, add 1.5 times of water, stir evenly, and set aside;

[0044] 2) Take 12 parts of sodium hypochlorite, 10 parts of polyferric trichlorid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com