A flexible glass fiber-based catalyst for vocs catalytic combustion and its preparation method and application

A glass fiber, catalytic combustion technology, used in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problem of short life, poor dispersion of active components, specific surface area Small and other problems, to achieve the effect of sufficient resources, low price, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

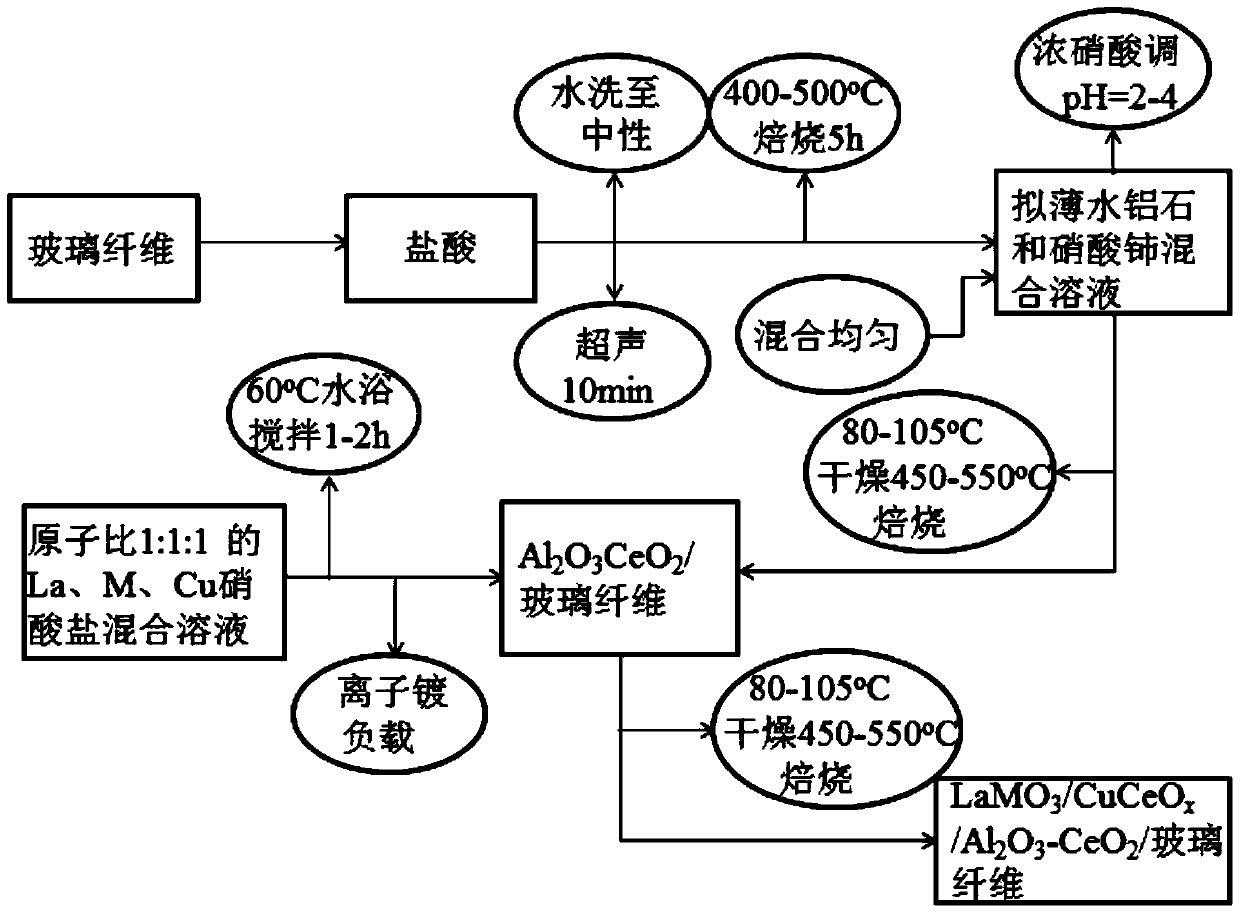

Method used

Image

Examples

Embodiment 1

[0027] (1) Immerse the glass fiber completely in 10wt.% hydrochloric acid for 1 hour, take it out and wash it with water until neutral, then put it into deionized water for 80 Hz ultrasonication for 10 minutes, dry it and bake it in a muffle furnace at 500°C for 5 hours.

[0028] (2) Mix pseudo-boehmite (calculated as alumina) and cerium nitrate hexahydrate according to the metal atomic ratio of 2:1, dissolve in 100mL distilled water, stir until completely dissolved, add concentrated nitric acid drop by drop to pH =2, continue to stir for 2 hours, then immerse the glass fiber obtained in the above (1) into the solution, after soaking for 2 hours, take it out and blow it with a high-pressure air gun to blow out the excess solution in the three-dimensional micropores of the glass fiber, and age for 24 hours at 80°C Dry, and then bake in a muffle furnace at 500°C for 5h after drying.

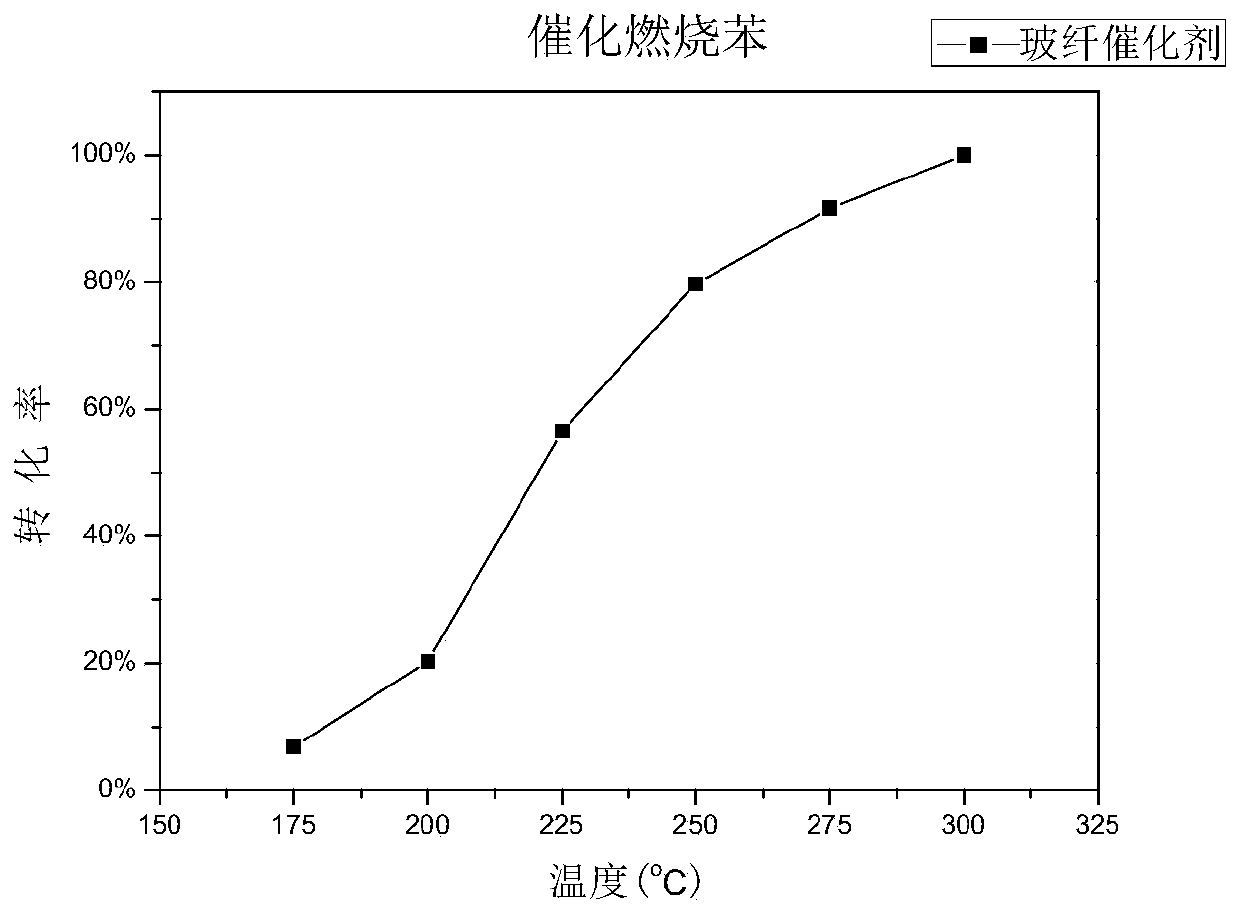

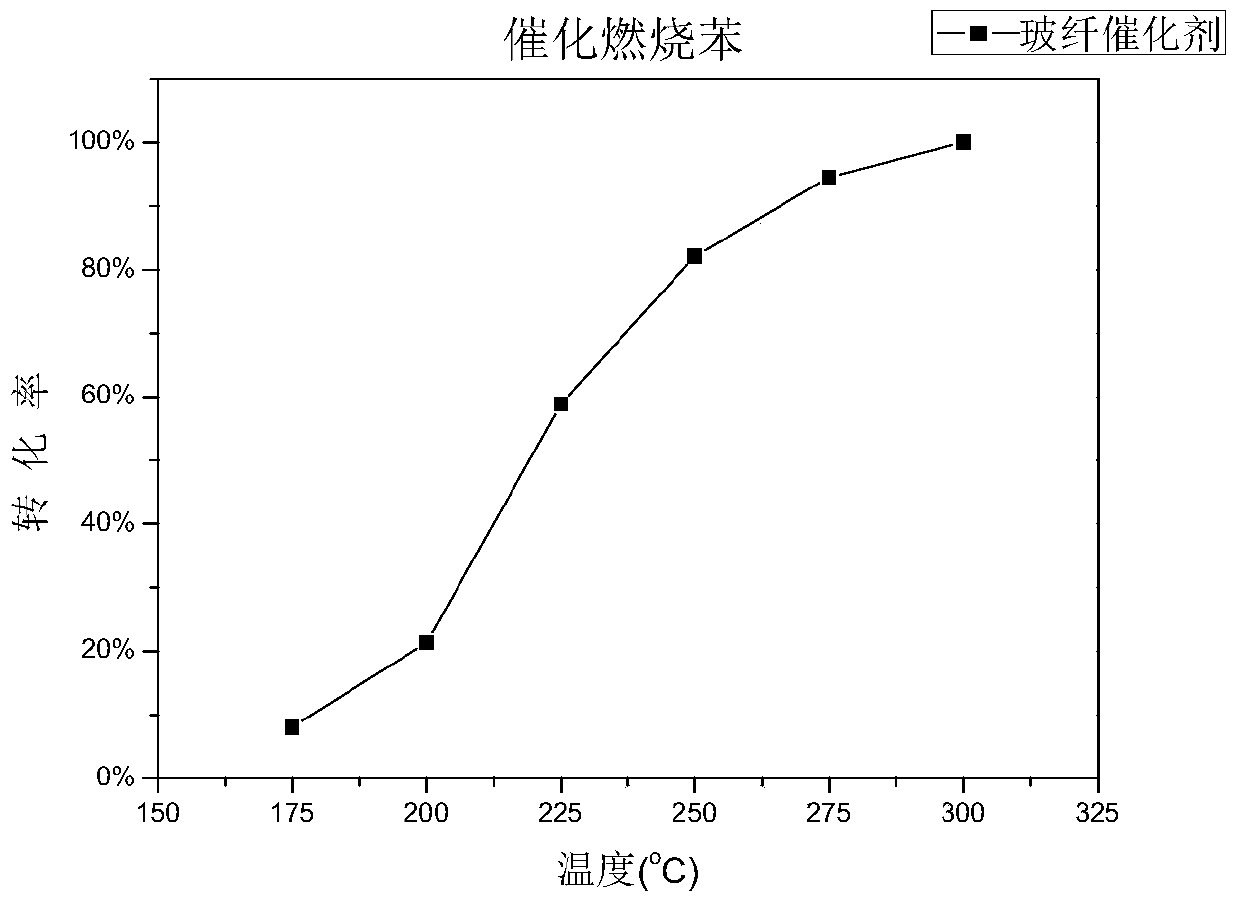

[0029] (3) Add the nitrates of lanthanum, chromium, and copper into 150mL of distilled water ac...

Embodiment 2

[0032] (1) Completely immerse the glass fiber in 20 wt.% hydrochloric acid for 1 hour, take it out and wash it until neutral, then put it into deionized water for 80 Hz ultrasonication for 10 minutes, dry it and bake it in a muffle furnace at 500°C for 5 hours.

[0033] (2) Mix pseudo-boehmite (calculated as alumina) and cerium nitrate hexahydrate according to the metal atomic ratio of 2:1, dissolve in 100mL distilled water, stir until completely dissolved, add concentrated nitric acid drop by drop to pH =2, continue to stir for 2 hours, then immerse the glass fiber obtained in the above (1) into the solution, after soaking for 2 hours, take it out and blow it with a high-pressure air gun to blow out the excess solution in the three-dimensional micropores of the glass fiber, and age for 24 hours at 80°C Dry, and then bake in a muffle furnace at 500°C for 5h after drying.

[0034](3) Add the nitrates of lanthanum, iron, and copper into 150mL of distilled water according to the ...

Embodiment 3

[0037] (1) Completely immerse the glass fiber in 20 wt.% hydrochloric acid for 1 hour, take it out and wash it until neutral, then put it into deionized water for 80 Hz ultrasonication for 10 minutes, dry it and bake it in a muffle furnace at 500°C for 5 hours.

[0038] (2) Mix pseudo-boehmite (calculated as alumina) and cerium nitrate hexahydrate according to the metal atomic ratio of 2:1, dissolve in 100mL distilled water, stir until completely dissolved, add concentrated nitric acid drop by drop to pH =2, continue to stir for 2 hours, then immerse the glass fiber obtained in the above (1) into the solution, after soaking for 2 hours, take it out and blow it with a high-pressure air gun to blow out the excess solution in the three-dimensional micropores of the glass fiber, and age for 24 hours at 80°C Dry, and then bake in a muffle furnace at 500°C for 5h after drying.

[0039] (3) Add the nitrates of lanthanum, cobalt, and copper into 150mL of distilled water according to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com