Lactobacillus plantarum and application thereof in fermenting cured meat products

A technology of Lactobacillus plantarum and cured bacon, which is applied in the field of microorganism and meat food fermentation, can solve the problems of less research and application of starter, acidic taste of fermented sausage, and inconformity with eating habits, etc., to improve the nutritional value of products and promote The degradation of protein and the formation of flavor, and the effect of inhibiting the growth and reproduction of spoilage microorganisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The biological characteristic of embodiment 1 plant Lactobacillus (Lactobacillus plantarum) CGMCCNo.11341

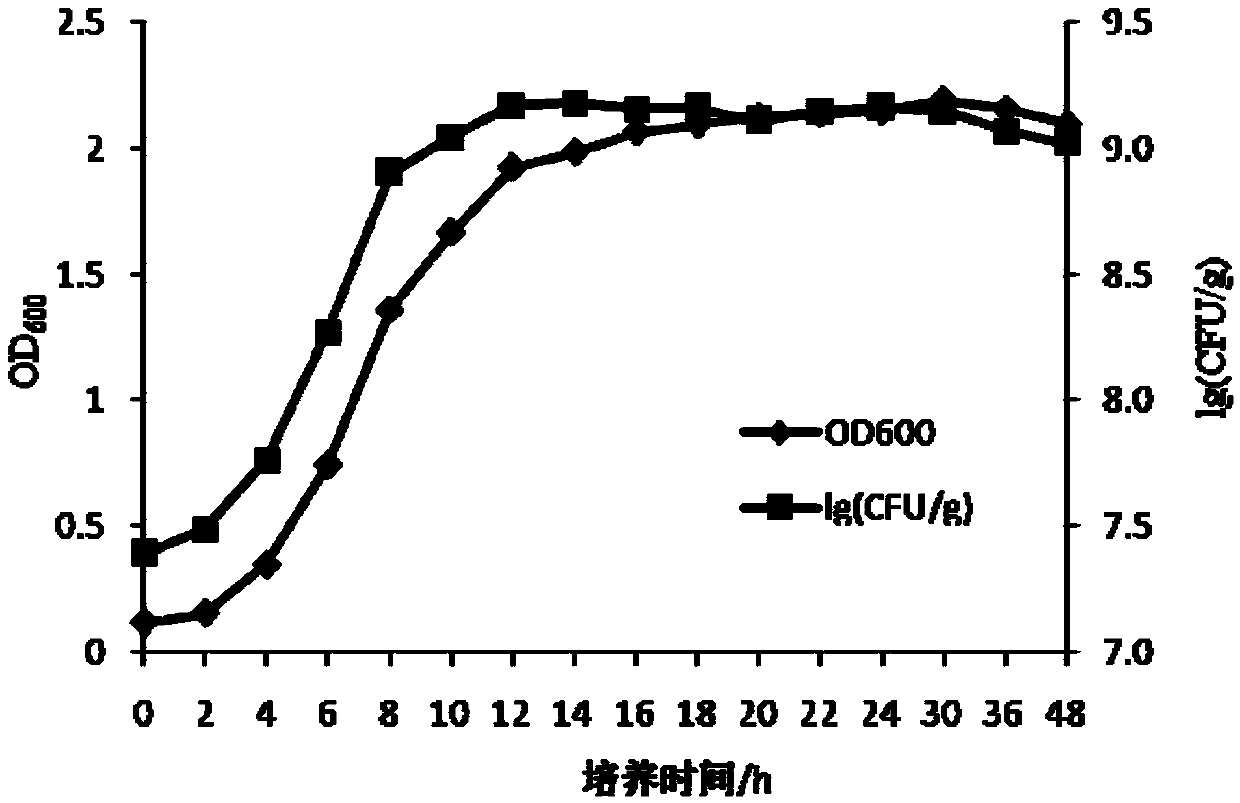

[0046] 1. Determination of growth curve

[0047] Lactobacillus plantarum (Lactobacillus plantarum) CGMCCNo.11341 preserved in glycerol tubes was inoculated into MRS nutrient broth for activation twice, and the fresh bacterial solution was transferred to fresh MRS broth medium at 2% inoculum, at 37°C, Shake culture at 200r / min, take samples every 2h for the first 24h, take samples at 30h, 36h and 48h after 24h, measure the number of viable bacteria and the turbidity of the bacterial suspension by pouring the plate method and photoelectric turbidimetry (OD600) respectively, each Time point to do 3 repetitions.

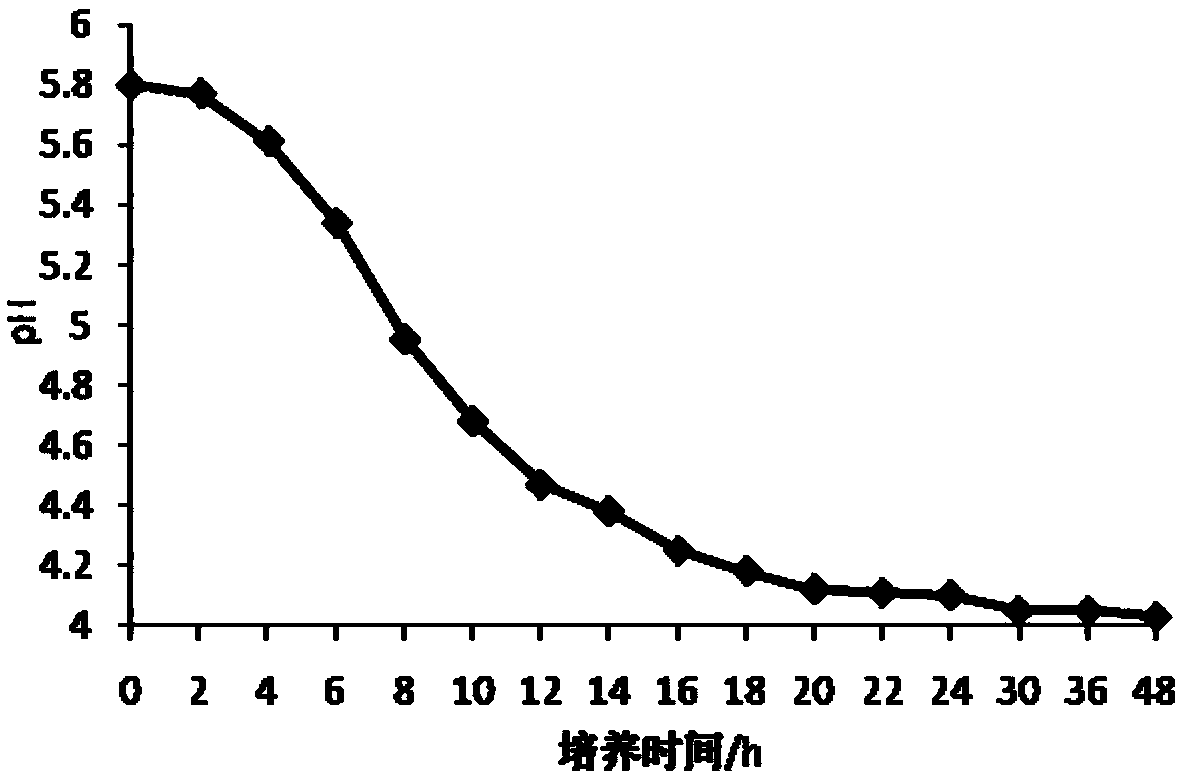

[0048] 2. Determination of acid production curve

[0049] Bacterial strain cultivation and regular sampling were the same as above, and the pH value of the bacterial suspension was measured with a pH meter, with 3 repetitions at each time point.

[0050] ...

Embodiment 2

[0051] Embodiment 2 fermentation agent and preparation method thereof

[0052] The strains stored in glycerol tubes were transferred and activated twice, then inoculated in MRS broth medium at an inoculation ratio of 2%, and cultured at 37°C and 200r / min for 24 hours to obtain a bacterial suspension, which was centrifuged at 5000rpm for 15min and then discarded. Add an equal volume of sterile normal saline to re-suspend the bacteria in the upper culture medium, then centrifuge to discard the supernatant, then add 1 / 10 of the volume of the bacterial suspension in normal saline and mix to obtain a concentrated bacterial solution, add 4 times the volume of the concentrated bacterial solution After lyoprotectant (10% skimmed milk), freeze-drying makes starter, adopts gradient dilution and pour plate method to record that the bacterial activity in this dry powder starter is 10 10 CFU / g.

Embodiment 3

[0053] Application of embodiment 3 leavening agent in traditional bacon products

[0054] 1) Select 10kg of fresh rump meat with a fat-to-lean ratio of 3:7, remove impurities on the meat surface, and divide it into strips about 30cm long, 5cm wide, and 5cm thick.

[0055] 2) Accurately weigh 0.01g starter dry powder, and configure 700g, 2% glucose solution to dissolve it, according to the weight of the raw meat and the volume of the injection solution, evenly inject the glucose solution in which the starter has been dissolved into the raw meat, so that The amount of Lactobacillus plantarum (Lactobacillus plantarum) CGMCCNo.11341 added in raw meat is about 10 4 CFU / g raw meat.

[0056] 3) Vacuum tumbling and pickling, using a vacuum tumbling machine, the tumbling time is 10 hours; each work is 20 minutes, the interval is 40 minutes, and the effective tumbling time is 200 minutes.

[0057] 4) Weigh 0.6g of sodium nitrite, dissolve it in a small amount of water, and apply it ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com