Method for preparing nano-hydroxyapatite-protein artificial bone imitation materials

A nano-hydroxyapatite and protein technology, applied in medical science, tissue regeneration, prosthesis, etc., can solve the problems of low content of organic components, waste of raw materials, and unsatisfactory content ratio of organic and inorganic components in natural bone, etc., to achieve The effect of simple process, easy operation and good controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

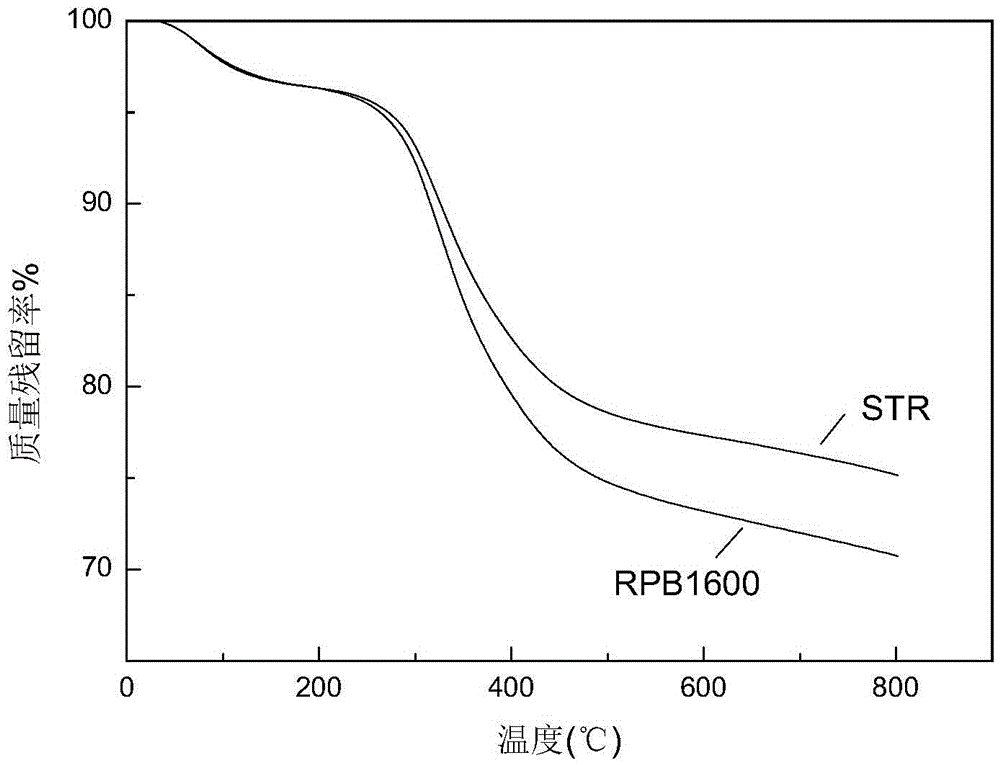

[0046] A kind of preparation method of nano-hydroxyapatite material (does not contain albumen), comprises the steps:

[0047] Prepare 2L each of 0.1mol / L calcium nitrate and sodium phosphate solutions, adjust the calcium nitrate to pH = 10 with sodium hydroxide solution, and feed into the rotary The packed bed was reacted at room temperature, and the rotating speed of the packed bed was 1600r / min; the reacted suspension was aged at room temperature overnight, filtered, washed, and dried at 80°C for 10 hours. The product was ground into powder, poured into a mold, and pressed for 5 minutes under a pressure of 5 MPa to form a nano-hydroxyapatite material column with a diameter of 13.1 mm and a height of 10.5 mm. The nano-hydroxyapatite prepared in this example is short rod-shaped grains, with an average diameter of 9.6±2.1nm, an average length of 35.9±10.5nm, and an organic content of zero. The pressure of the cylindrical material obtained by die-casting is 0.3Gpa .

Embodiment 2

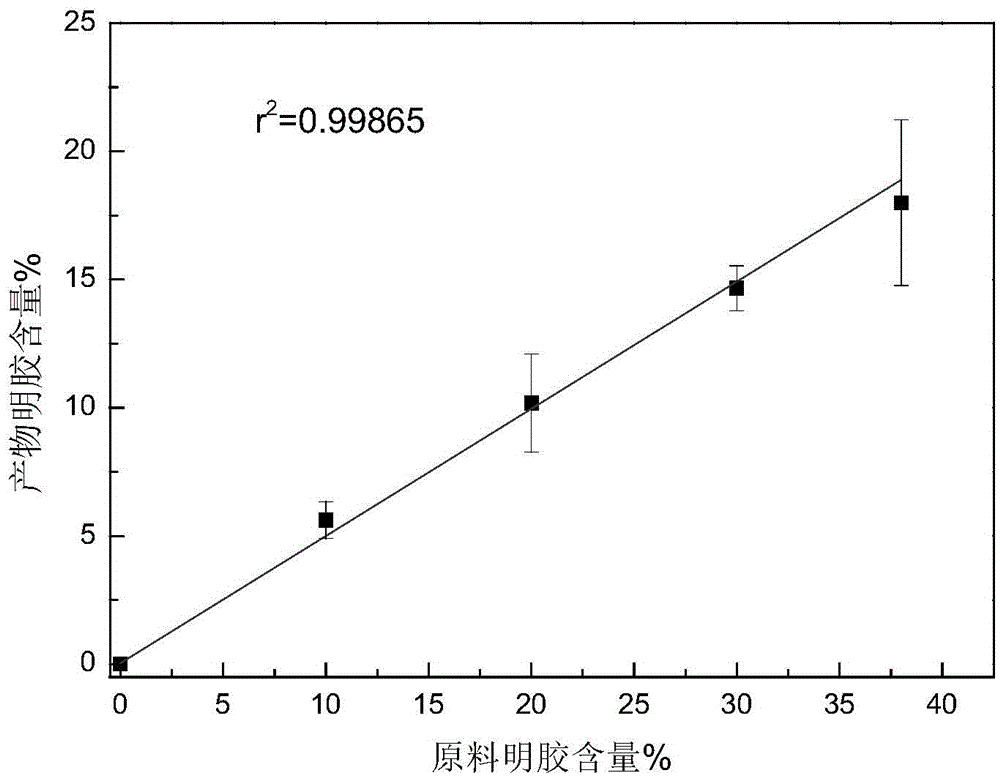

[0049] A preparation method of nano-hydroxyapatite-gelatin artificial bone-like material, comprising the steps of:

[0050] Prepare 2L each of 0.1mol / L calcium nitrate and sodium phosphate solutions, add 2.244g gelatin to the calcium nitrate solution, stir until the gelatin is completely dissolved and mix evenly, and adjust the pH to 10 with sodium hydroxide solution, and use calcium nitrate-gelatin The feed flow rate of solution 67.5L / h and sodium phosphate 40.5L / h was passed into the rotary packed bed, and reacted at room temperature, and the rotating speed of the rotary packed bed was 1600r / min; Filter, wash, and dry at 80°C for 10 hours. The product was ground into powder, poured into a mold, and pressed for 5 minutes under a pressure of 5 MPa to form a nano-hydroxyapatite-gelatin composite column with a diameter of 13.1 mm and a height of 10.3 mm. The nano-hydroxyapatite-gelatin composite material prepared in this embodiment is a short rod-shaped grain, with an average d...

Embodiment 3

[0052] A preparation method of nano-hydroxyapatite-gelatin artificial bone-like material, comprising the steps of:

[0053] Prepare 2L each of 0.1mol / L calcium nitrate and sodium phosphate solutions, add 5.05g gelatin to the calcium nitrate solution, stir until the gelatin is completely dissolved and mix evenly, and adjust the pH to 10 with sodium hydroxide solution, and use calcium nitrate-gelatin The feed flow rate of solution 67.5L / h and sodium phosphate 40.5L / h was passed into the rotary packed bed, and reacted at room temperature, and the rotating speed of the rotary packed bed was 1600r / min; Filter, wash, and dry at 80°C for 10 hours. The product was ground into powder, poured into a mold, and pressed for 5 minutes under a pressure of 5 MPa to form a nano-hydroxyapatite-gelatin composite column with a diameter of 13.2 mm and a height of 11.8 mm. The nano-hydroxyapatite-gelatin composite material prepared in this embodiment is a short rod-shaped grain, with an average di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com