Nitric oxide luminous particle and preparation method thereof, nitric oxide luminous body and luminous device

A technology of nitrogen oxides and luminescent particles, which is applied in the direction of semiconductor devices, chemical instruments and methods, and luminescent materials, can solve the problems of decreased luminous intensity of phosphor powder, low conversion efficiency of weak energy, and low luminous efficiency of phosphor powder. The structure is solid and stable, the manufacturing method is simple and reliable, and the effect of anti-aging and light decay is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

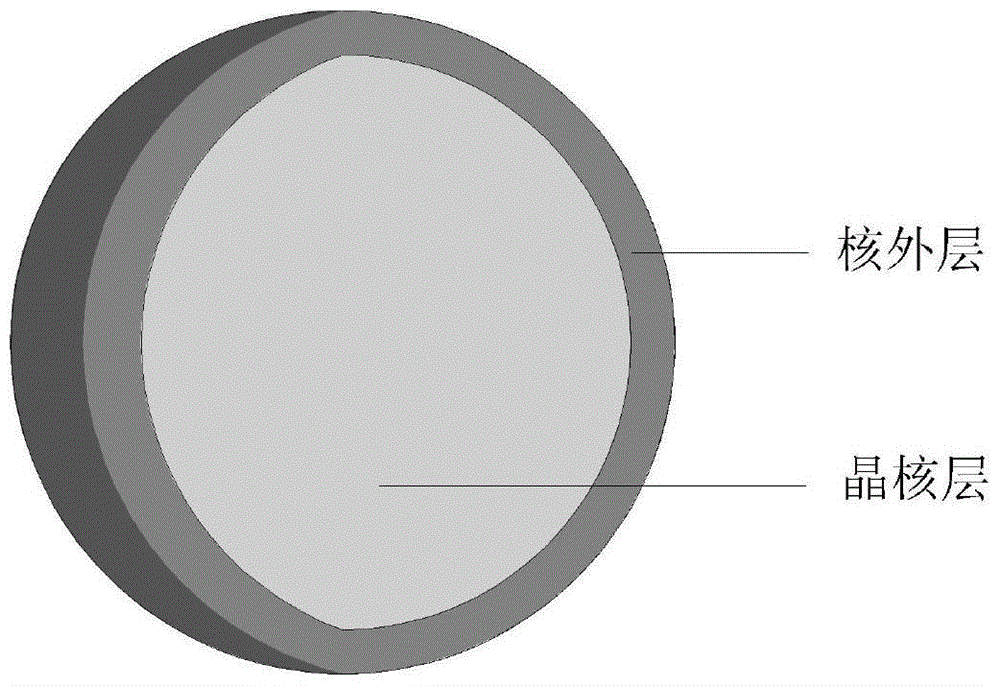

preparation example Construction

[0053] The preparation method 1 of a nitrogen oxide luminescent particle and its preferred solution proposed by the present invention includes the following specific steps:

[0054] Step 1: Use the nitrides, oxides or halides of M, A, B, R as raw materials, according to the general chemical formula M m-m1 A a1 B b1 o O1 N n1 :R m1 The stoichiometric ratio of the cations in the composition weighs the required raw materials;

[0055] Step 2: Mix the raw materials weighed in step 1 uniformly in a nitrogen atmosphere to form a mixed material; wherein the mixing time of the raw materials is 1-5 hours;

[0056] Step 3: Roast the mixture obtained in step 2 at a high temperature in a roasting atmosphere, then lower the temperature to a predetermined temperature, and then pass in nitrogen-oxygen mixed gas or air for low-temperature roasting to obtain a semi-finished product of nitrogen oxide luminescent particles; wherein:

[0057] The calcination temperature is 1400-2000°C, and ...

Embodiment 1

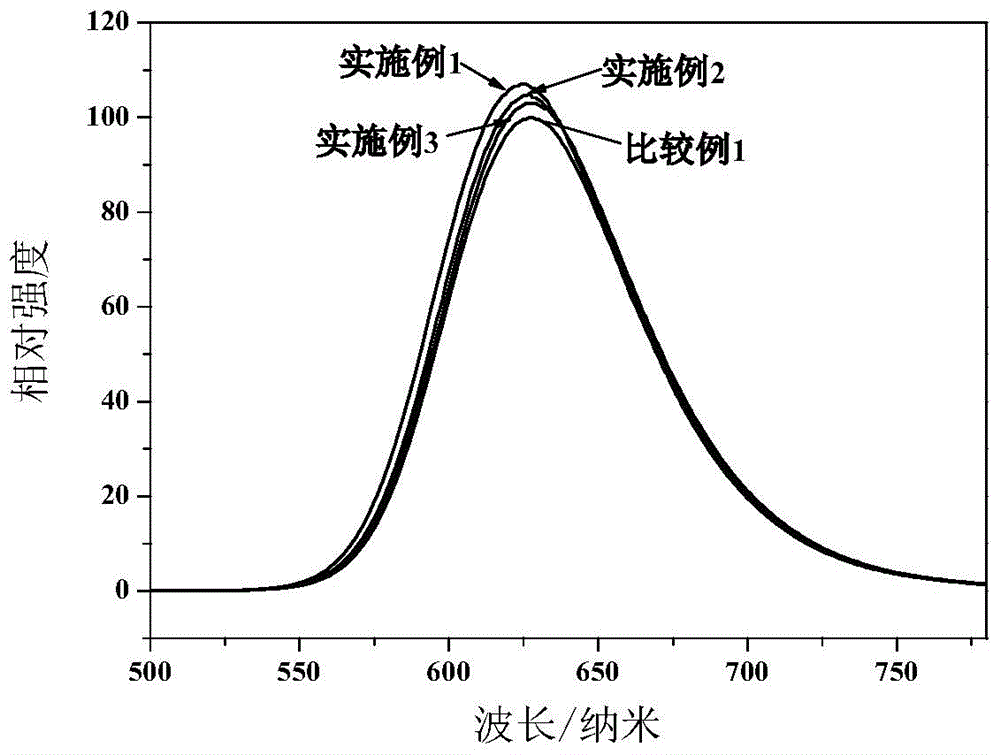

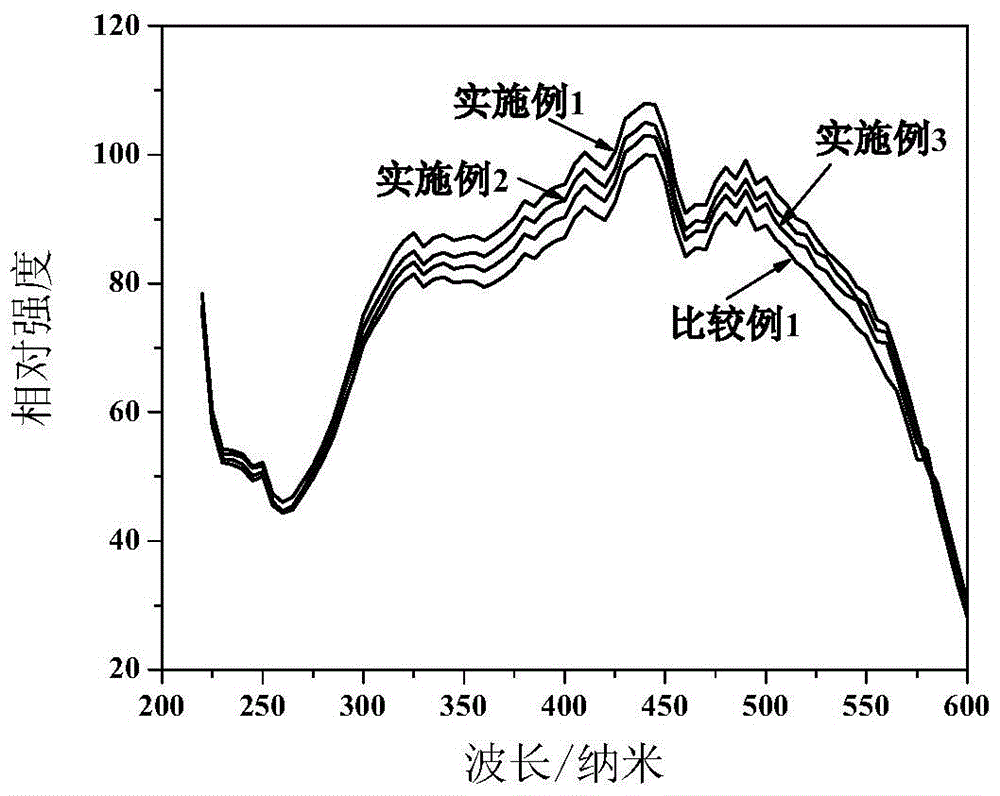

[0071] Weigh Ca 3 N 2 0.319g, Sr 3 N 2 9.288g, AlN4.412g, Si 3 N 4 5.033g, Eu 2 o 3 0.947g, the above raw materials were fully mixed in a nitrogen atmosphere for 2 hours, put into a molybdenum crucible, and then quickly moved into a tube furnace, and then gradually heated up to 1800°C under the protection of a nitrogen atmosphere, and kept for 10h; cooled to 400°C, Pass nitrogen-oxygen mixture gas (20% oxygen by volume) at a speed of 2L / min for roasting, the roasting time is 4h, crush the obtained luminescent particles and sieve, put the sieved luminescent particles into deionized water Stir for 30 minutes, then suction filter, and finally wash until the conductivity is 7.21 μs / cm, and then dry to obtain the finished nitrogen oxide luminescent particles. For the emission spectrum see figure 2 , the excitation spectrum is shown in image 3 , its luminous intensity is shown in Table 1, which is higher than that of Comparative Example 1, and its thermal quenching spectr...

Embodiment 2

[0073] Weigh Ca 3 N 2 0.537g, Sr 3 N 2 8.963g, AlN4.457g, Si 3 N 4 5.085g, Eu 2 o 3 0.957g, the above raw materials were fully mixed in a nitrogen atmosphere for 2 hours, put into a molybdenum crucible, and then quickly moved into a tube furnace, then gradually heated up to 1800°C under the protection of a nitrogen atmosphere, and kept for 10h; cooled to 400°C, Pass nitrogen-oxygen mixture gas (15% oxygen by volume) at a speed of 2L / min for roasting, the roasting time is 4h, crush the obtained luminescent particles and sieve, put the sieved luminescent particles into deionized water Stir for 30 minutes, then suction filter, and finally wash until the conductivity is 6.12 μs / cm, and dry to obtain the finished nitrogen oxide luminescent particles. For the emission spectrum see figure 2 , the excitation spectrum is shown in image 3 , the thermal quenching spectrum see Figure 4 . The crystal nucleus layer of nitride luminescent particles is Ca 0.1 Sr 0.85 AlSiN 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com