Method for preparing high-temperature blending epoxy asphalt curing agent for paving

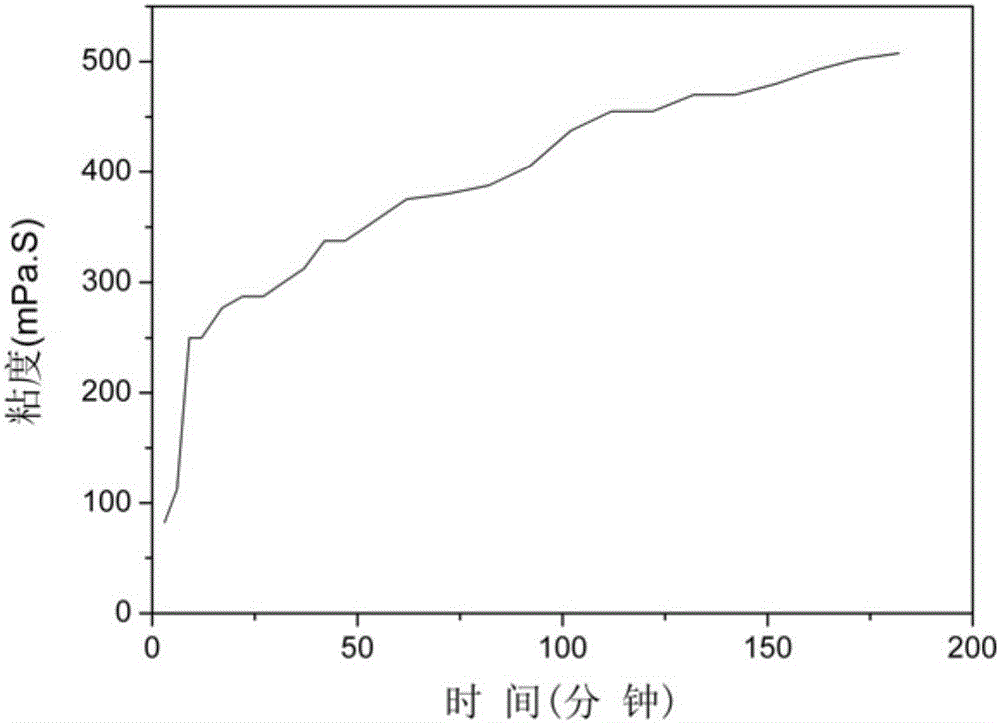

An epoxy asphalt, high-temperature mixing technology, applied in the field of asphalt materials, can solve the problems of tight holding time, long holding time, low mixing temperature, etc., and achieve the effects of improving construction technology, long holding time, and easy to enlarge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1) First, dissolve 10 parts of hyperbranched poly(3-ethyl-3-hydroxymethylbutylene oxide) and 10 parts of aminobenzoic acid in 100 parts of N,N-dimethyl In the formamide solvent, add 1 part of catalyst potassium hydroxide therein again;

[0029] 2) Then, feed nitrogen into the reaction system, raise the temperature to 80°C for 8 hours under stirring, and then raise the temperature to 120°C for 12 hours;

[0030] 3) After the reaction is finished, the solvent is distilled off under reduced pressure, and 50 parts of low boiling point solvent acetone are added thereto, filtered after 300 parts of settling agent ether is settled, washed until the filtrate is colorless, and then dried in a vacuum oven at 80°C to obtain Aromatic aminated hyperbranched polyether containing 100% aromatic aminated hyperbranched polyether;

[0031] 4) Mix aromatic aminated hyperbranched polyether and polysebacic anhydride in a mass ratio of 25:75 to prepare an epoxy asphalt curing agent.

[0032...

Embodiment 2

[0037] 1) First, dissolve 15 parts of hyperbranched poly(3-methyl-3-hydroxymethylbutylene oxide) and 10 parts of aminophenylacetic acid in 50 parts of N,N-dimethylethyl ether by mass parts In the amide solvent, add 1 part of catalyst sodium hydroxide therein again;

[0038] 2) Then, feed nitrogen into the reaction system, raise the temperature to 100°C for 6 hours under stirring, and then raise the temperature to 130°C for 10 hours;

[0039] 3) After the reaction is finished, the solvent is distilled off under reduced pressure, and 50 parts of low-boiling point solvent ethanol is added thereto, filtered after 400 parts of settling agent petroleum ether is settled, washed until the filtrate is colorless, and then dried in a vacuum oven at 100°C. An aromatic aminated hyperbranched polyether having an aromatic aminated hyperbranched polyether content of 100% is obtained;

[0040] 4) Mix aromatic aminated hyperbranched polyether and polyazalic anhydride in a mass ratio of 25:75 t...

Embodiment 3

[0043]1) First, 20 parts of hyperbranched poly(3,3-dimethylol-butylene oxide) and 20 parts of aminophenylpropionic acid are dissolved in 200 parts of N-methyl-2-pyrrolidone by mass parts In the solvent, add 1 part of catalyst triethylamine to it again;

[0044] 2) Then, feed nitrogen into the reaction system, heat up to 120°C for 6 hours under stirring, and then heat up to 160°C for 3 hours;

[0045] 3) After the reaction is finished, the solvent is distilled off under reduced pressure, and 80 parts of low boiling point solvent N,N-dimethylformamide is added thereto, filtered after 350 parts of settling agent n-hexane is settled, washed until the filtrate is colorless, and then drying in a vacuum oven at 90° C. to obtain an aromatic aminated hyperbranched polyether with an aromatic aminated hyperbranched polyether content of 100%;

[0046] 4) Mix aromatic aminated hyperbranched polyether and polysebacic anhydride in a mass ratio of 25:75 to prepare an epoxy asphalt curing age...

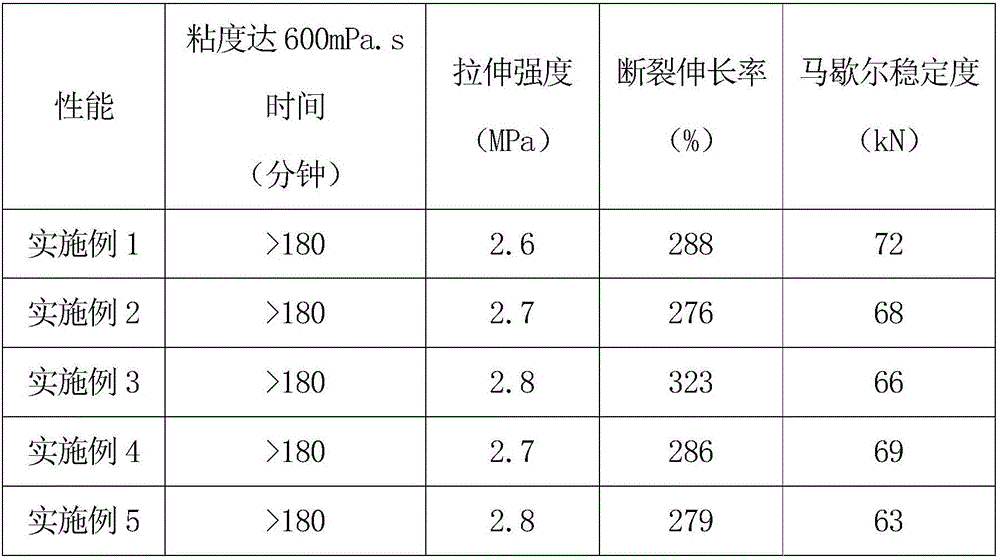

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com