Double-pore-channel crystallization aluminosilicate molecular sieve catalyst and preparing method thereof

A technique of aluminosilicate and molecular sieve, which is applied in the direction of molecular sieve catalysts, catalyst carriers, chemical instruments and methods, etc., can solve the problems of less research, achieve the improvement of propylene ethylene ratio, propylene selectivity and propylene ethylene ratio, and improve acid Effect of Center Strength and Density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Catalyst preparation

[0044] Preparation of dual-channel aluminosilicate molecular sieve carrier:

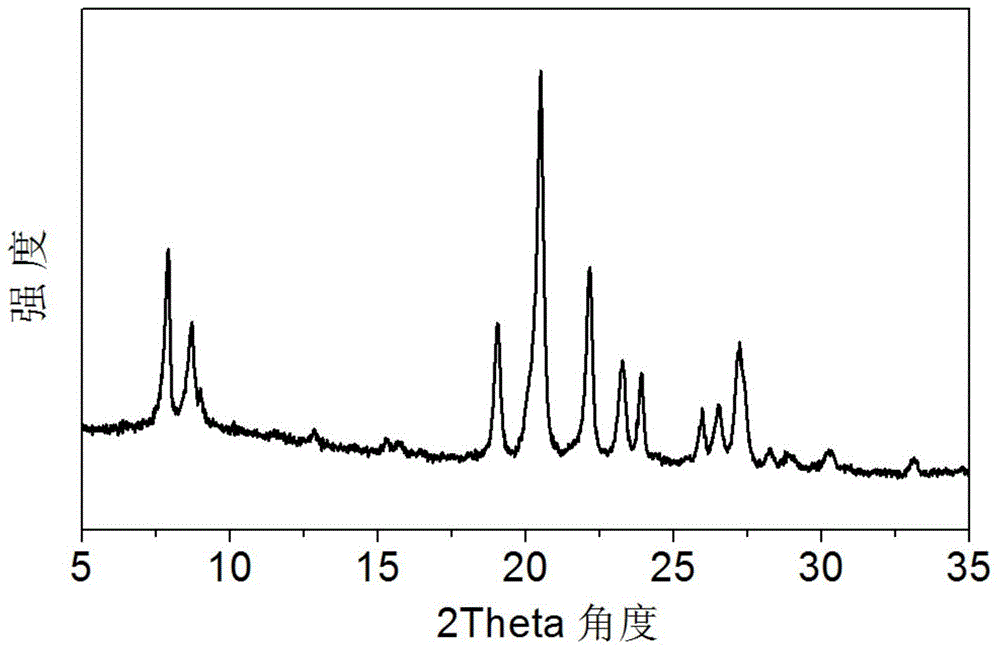

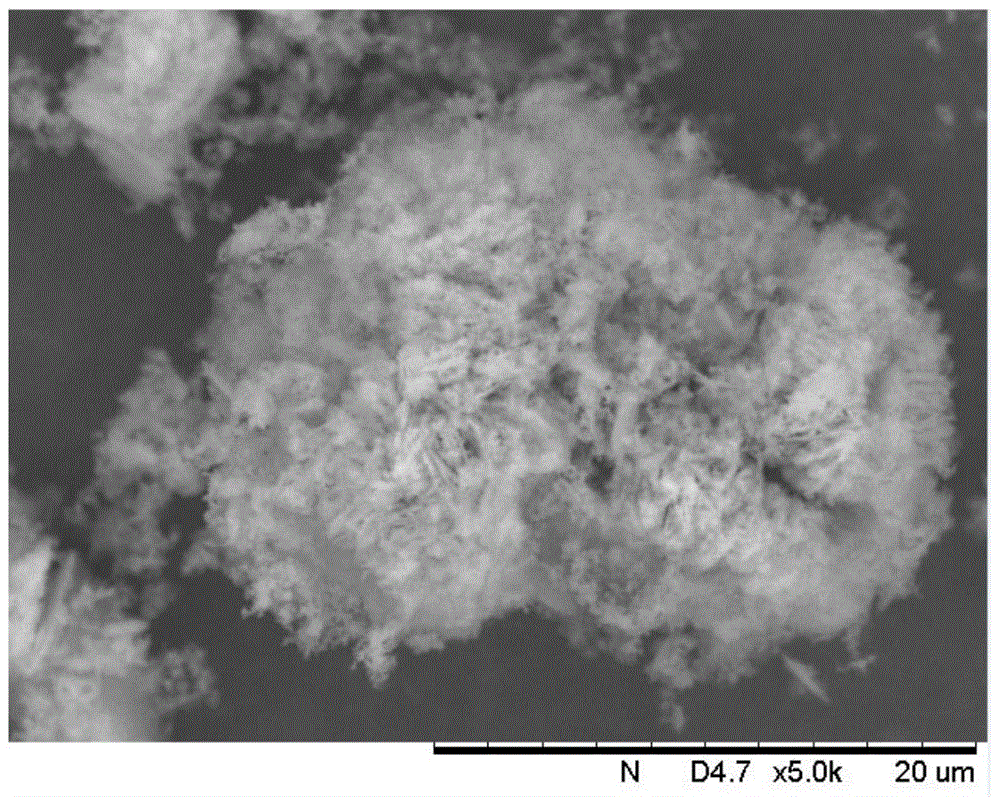

[0045] 2.72g templating agent hexamethylene-1,6-bis(trimethylammonium bromide)[(CH 3 ) 3 N + -(CH 2 ) 6 -N + (CH 3 ) 3 ]Br 2 was dissolved in 10 g of deionized water, and 40 g of silica sol (SiO 2 Mass content 30%), stir rapidly until the mixture is uniform. In addition, 1.92 g of sodium chloride was dissolved in 10 g of deionized water, and sodium hydroxide was added to adjust the pH to 11-12, and then 0.82 g of sodium metaaluminate was added under stirring. Add the aluminum salt solution to the above-mentioned silica sol containing the template agent, and the molar ratio of the template agent, silicon oxide, aluminum oxide, sodium oxide and deionized water in the obtained uniform white gel is 1.5:40:1.0:6.2 :500. Transfer the gel into a synthesis kettle, hydrothermally crystallize at 180°C for 48 hours, and then centrifuge, wash, dry, and roast the solid pr...

Embodiment 2

[0054] Catalyst preparation

[0055] Preparation of dual-channel aluminosilicate molecular sieve carrier:

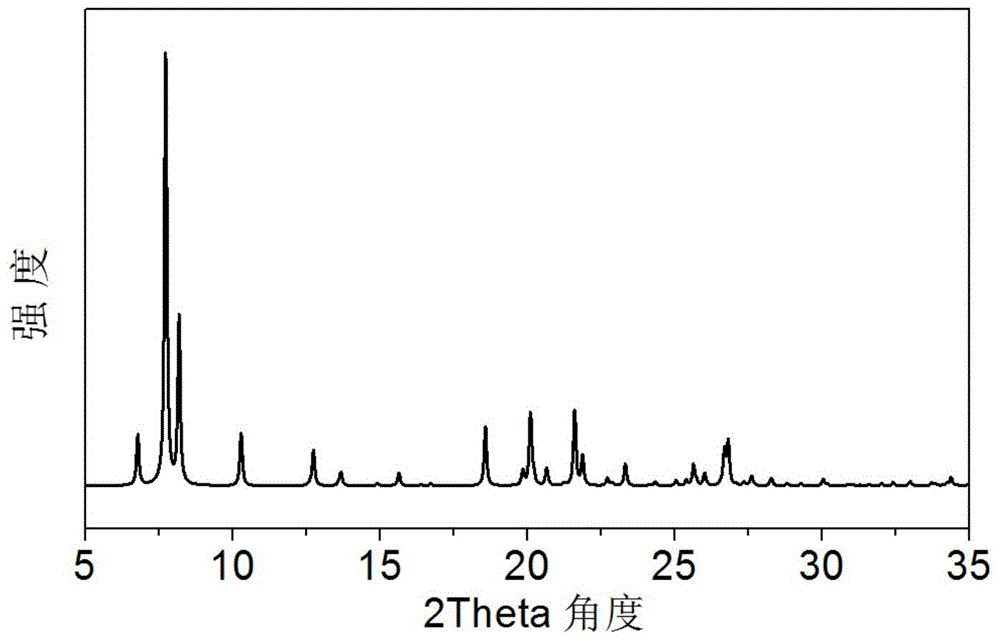

[0056] 5.02g templating agent decamethylene-1,6-bis(trimethylammonium bromide)[(CH 3 ) 3 N + -(CH 2 ) 10 -N + (CH 3 ) 3 ]Br 2 was dissolved in 10 g of deionized water, and 15 g of silica sol (SiO 2 Mass content 30%), stir rapidly until the mixture is uniform. In addition, 1.91 g of sodium bromide was dissolved in 10 g of deionized water, and sodium hydroxide was added to adjust the pH to 10-11, and then 0.25 g of sodium metaaluminate was added under stirring. Add the aluminum salt solution to the above-mentioned silica sol containing the template agent, and the molar ratio of the template agent, silicon oxide, aluminum oxide, sodium oxide and deionized water in the resulting uniform white gel is 4.0:50:1.0:6.2 : 3000, the gel is transferred to a synthesis kettle, hydrothermally crystallized at 200°C for 24 hours, and the solid product is then centrifugally was...

Embodiment 3

[0087] Response evaluation

[0088] Catalyst performance evaluation was carried out using a micro-fixed-bed reactor. The HDM1, Mg / HDM1, HDM2 and Mg / HDM2 prepared in Examples 1 and 2 were respectively pressed into tablets, crushed and sieved into 40-60 mesh samples, and 2 g of samples were taken respectively and put into stainless steel reactors. Activated for 1 hour, purged under nitrogen atmosphere for 0.5 hours and lowered to the predetermined reaction temperature of 480°C. Switch to the methanol feed pump to pump methanol into the reactor, and the methanol feed weight space velocity is 2h -1 , The reaction product was analyzed online by gas chromatography, and the reaction results were shown in Table 1 when the feed was fed for 60 minutes.

[0089] On the crystalline aluminosilicate molecular sieve catalyst with ten-membered ring and twelve-membered ring double-channel channel prepared by the present invention, the reaction activity is high, the conversion rate of methano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com