Manufacturing method and special die for one-step-formed multi-curved-face integral bullet-proof plates

A multi-curved surface, one-time technology, applied in the direction of auxiliary molding equipment, molds, molding indenters, etc., can solve the problems of unsuitable mass production, high equipment requirements, and corner defects, etc., to achieve uniform product structure, high sintering density, Good effect of arc shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

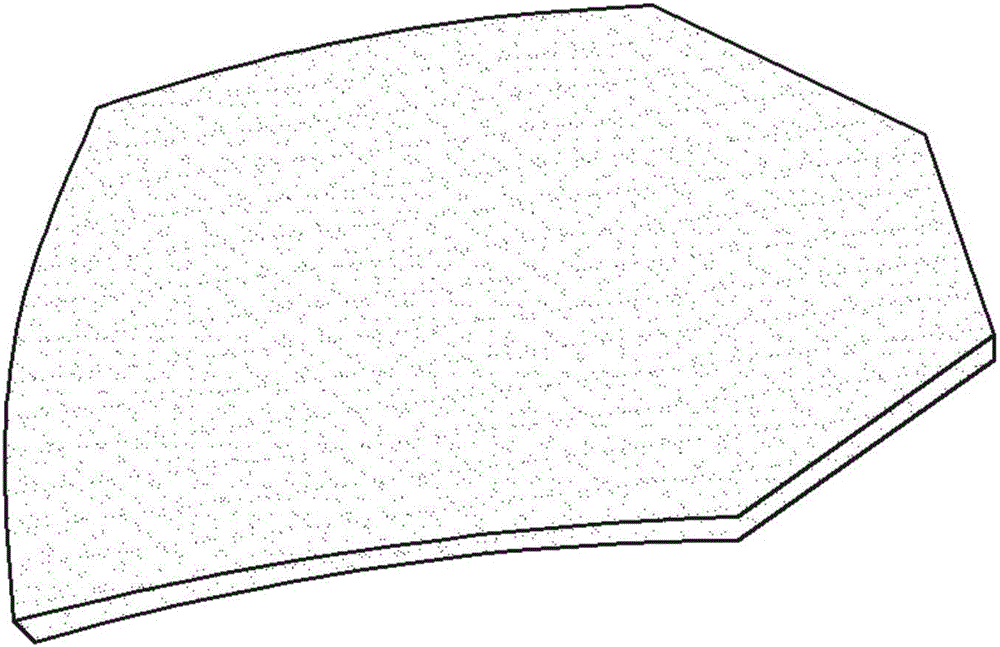

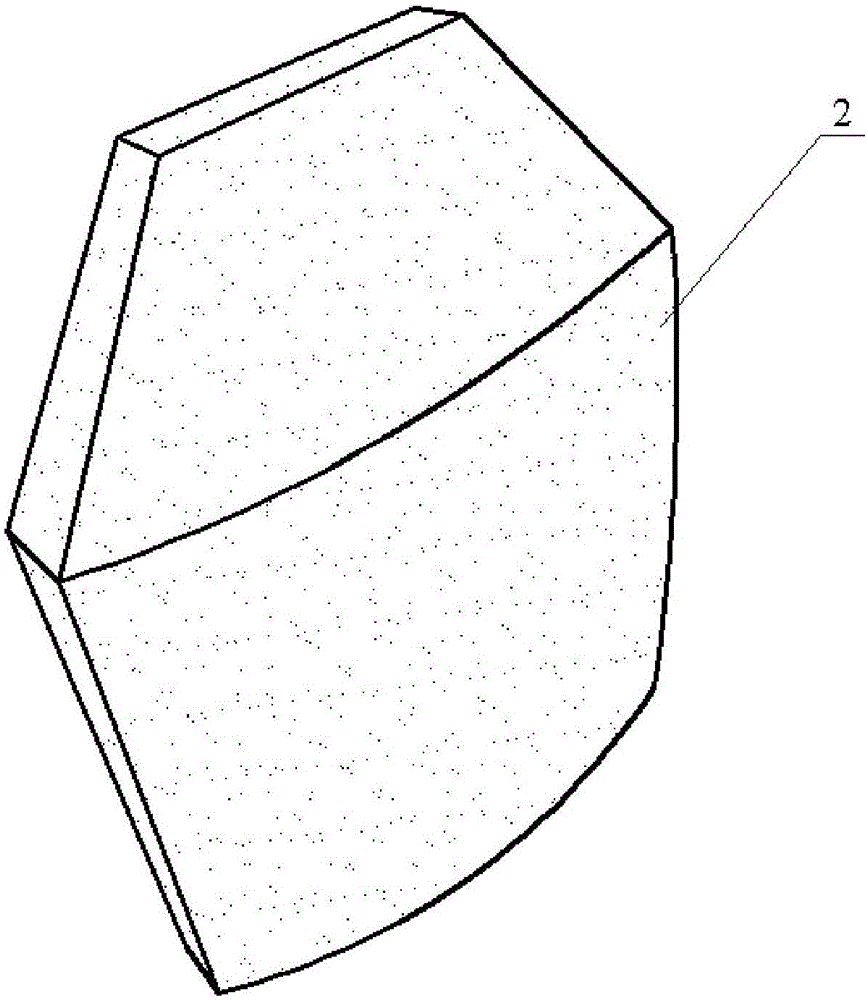

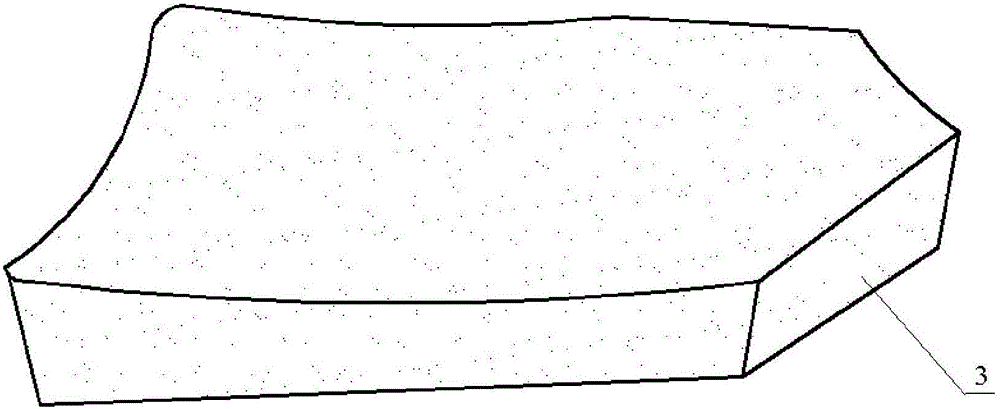

[0068] Embodiment 1, a special mold for forming multi-curved integral bulletproof plates at one time, the special mold includes an upper punch 2, a lower punch 3, an outer mold 4 and a plug 5;

[0069] A mold cavity 41 is provided in the outer mold 4; the two ends of the mold cavity 41 are connected with the outer mold 4, and an opening 42 for feeding is provided on the top of the outer mold 4, and the opening 42 matches the shape of the plug 5; the mold cavity 41 communicates with the opening 42; the mold cavity 41 of the outer mold 4 is used to install the upper punch 2 and the lower punch 3, and the upper punch 2 and the lower punch 3 can move freely in the mold cavity 41; the mold cavity 41, the upper punch The cross-sectional shapes of the punch 2 and the lower punch 3 are consistent.

[0070] The upper punch 2 and the lower punch 3 are respectively located at the two ends of the die cavity 41, the upper punch 2 is connected with the upper template of the semi-automatic h...

Embodiment 2

[0078] Embodiment 2: The preparation method of one-time molding multi-curved integral bulletproof plate (that is, the preparation of pressureless sintered silicon carbide bulletproof plate), the following steps are carried out in sequence:

[0079] (1) Powder preparation:

[0080] With 5 parts of nano carbon black (D 50 250nm), 2 parts of boron carbide powder (D 50 1.2μm) as a sintering aid;

[0081] In 100 parts silicon carbide micropowder, D 50 (median diameter) is 0.5 μm, add above-mentioned sintering aid, solution mass concentration is 5 parts of polyvinyl alcohol aqueous solution, 3 parts of oleic acid, 60 parts of deionized water are added in the ball mill successively, ball mill stirring (rotating speed is 50r / min) 5h, after mixing evenly, carry out spray drying, the inlet temperature is 250°C, the outlet temperature is 120°C, the rotation speed of the atomizing disc is 6000r / min, the speed regulation of the material pump is 200r / min, and the obtained spray granulat...

Embodiment 3

[0096] Embodiment 3: the preparation method (that is, prepare boron carbide ceramic bulletproof sheet material) of one-time molding multi-curved integral bulletproof sheet material, carry out the following steps successively:

[0097] (1) Powder preparation:

[0098] With 3 parts of nano carbon black (D 50 250nm), 6 parts silicon carbide powder (D 50 1 μm) as a sintering aid;

[0099] In 100 parts boron carbide fine powder, D 50 (median diameter) is 0.7 μ m, add the above-mentioned sintering aid, the solution mass concentration is 5 parts of polyvinyl alcohol aqueous solution of 10%, 1 part of glycerin, 2 parts of oleic acid, 80 parts of deionized water are added in the ball mill successively, and the grinding medium It is a pressureless sintered silicon carbide cylinder, stirred by a ball mill for 10 hours, and then spray-dried after mixing evenly. The inlet temperature is 250°C, the outlet temperature is 120°C, the rotation speed of the atomizing disc is 6000r / min, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com