Preparation method and application of nano zinc oxide photocatalyst

A nano-zinc oxide, photocatalyst technology, applied in the direction of zinc oxide/zinc hydroxide, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problem of difficult to remove moisture, expensive raw materials, Long reaction time and other problems, to achieve the effect of ensuring safety and environmental protection, mild and easily controllable reaction conditions, high purity and crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

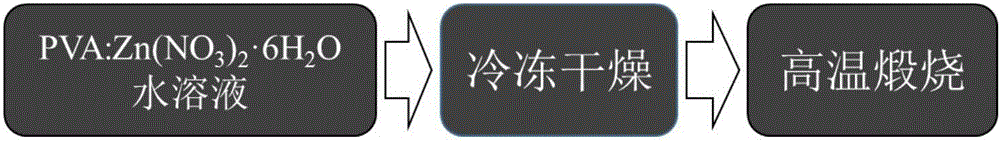

[0031] Weigh 2.0 g of polyvinyl alcohol (PVA) into a 500 ml flask, add 200 ml of deionized water, then put the flask into a 70°C water bath and heat and stir for 30 min to obtain a clear and transparent PVA aqueous solution. Add 8.0g zinc nitrate hexahydrate [Zn(NO 3 ) 2 ·6H 2 O] to obtain polyvinyl alcohol-zinc nitrate (PVA-Zn) solution. Pour the above solution into the sample tray of the lyophilizer and fully pre-freeze it at a low temperature; then place it in a lyophilizer with a cold trap temperature of -55°C and a working pressure of 10 Pa for 10 hours to obtain polyvinyl alcohol- Zinc nitrate (PVA-Zn) white foamy solid. Put the above solid into a muffle furnace and calcinate at 550° C. for 6 hours to obtain nanometer zinc oxide powder.

Embodiment 2

[0033] Weigh 4.0g of polyvinyl alcohol (PVA) into a 500ml flask, add 200ml of deionized water, then put the flask into a 70°C water bath and heat and stir for 30min to obtain a clear and transparent PVA aqueous solution. Add 16.0g zinc nitrate hexahydrate [Zn(NO 3 ) 2 ·6H 2 O] to obtain a mixed aqueous solution of polyvinyl alcohol-zinc nitrate (PVA-Zn). Pour the above aqueous solution into the sample tray of the lyophilizer and fully pre-freeze at a low temperature; then place it in a lyophilizer with a cold trap temperature of -55°C and a working pressure of 10Pa for 10 hours to obtain polyvinyl alcohol- Zinc nitrate (PVA-Zn) white foamy solid. Put the above solid into a muffle furnace and calcinate at 550° C. for 6 hours to obtain nanometer zinc oxide powder.

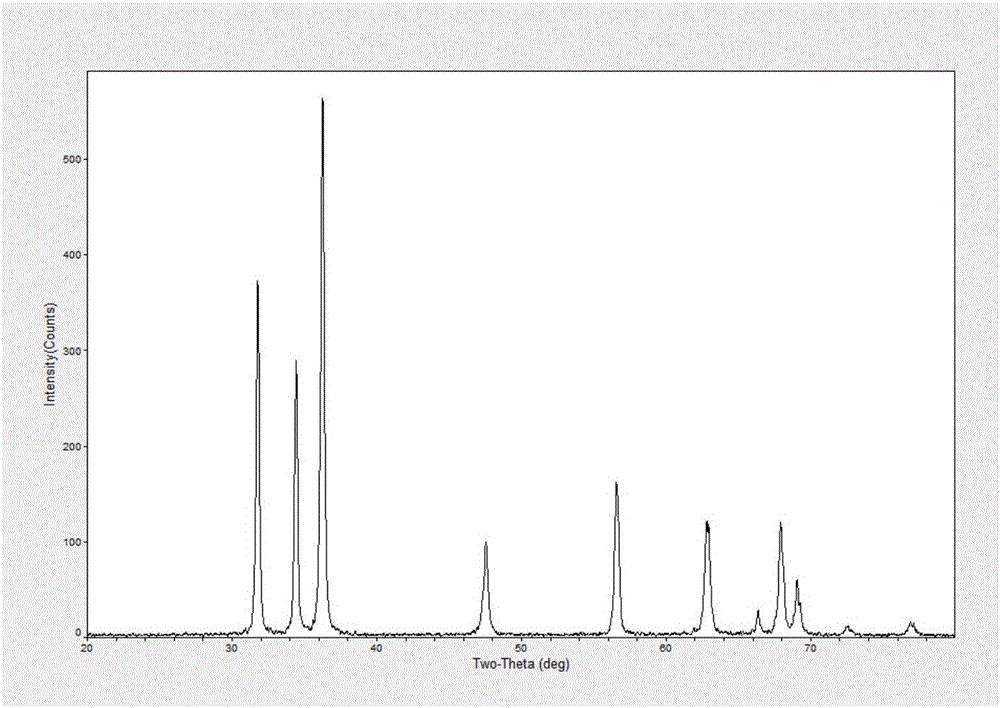

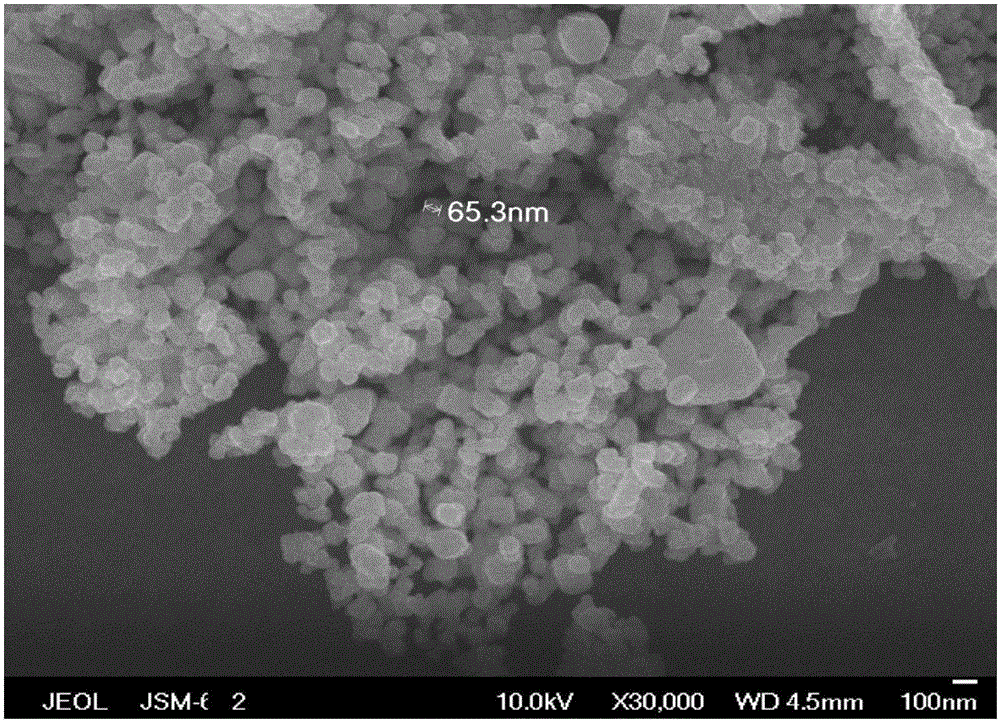

[0034] The X-ray diffraction pattern (XRD) of the nano zinc oxide photocatalyst prepared in the present embodiment is as follows figure 2 shown. Depend on figure 2 It can be seen that the prepared powder mat...

Embodiment 3

[0037]Weigh 10.0g of polyvinyl alcohol (PVA) into a 500ml flask, add 200ml of deionized water, then place the flask in a 70°C water bath and heat and stir for 30min to obtain a clear and transparent PVA aqueous solution. Add 40.0g zinc nitrate hexahydrate [Zn(NO 3 ) 2 ·6H 2 O] to obtain a mixed aqueous solution of polyvinyl alcohol-zinc nitrate (PVA-Zn). Pour the above aqueous solution into the sample tray of the lyophilizer and fully pre-freeze at a low temperature; then place it in a lyophilizer with a cold trap temperature of -55°C and a working pressure of 10Pa for 10 hours to obtain polyvinyl alcohol- Zinc nitrate (PVA-Zn) white foamy solid. Put the above solid into a muffle furnace and calcinate at 550° C. for 6 hours to obtain nanometer zinc oxide powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com