A diesel additive component and alcohol ester diesel containing the component

A technology of alcohol esters and diesel, which is applied in the petroleum industry, liquid carbon-containing fuels, biofuels, etc., can solve the problem of not fundamentally reducing the cost of biodiesel preparation, not having a good preventive effect, and biodiesel does not have Economic benefits and other issues, to achieve the effect of reducing petrochemical energy consumption, good economic benefits, and excellent anti-knock performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

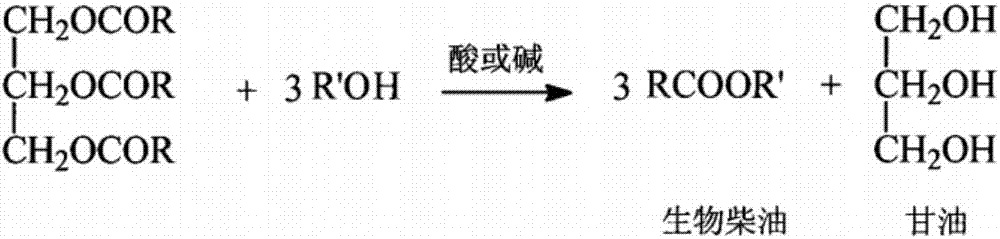

Method used

Image

Examples

Embodiment 1

[0030] An oxygen-containing alcohol ester diesel fuel, the raw material formula is: 40% of diesel oil, 20% of dimethyl carbonate, 5% of propylene glycol, 30% of biomass oil, 2‰ of cerium oxide particles, corrosion inhibitor 0.8‰ agent, 1.2‰ antioxidant and 1‰ anti-swelling agent; wherein, the diesel oil is national standard diesel oil, the purity of dimethyl carbonate is 95%, the purity of propylene glycol is 95%, and the purity of biomass oil is 98%. %, the average particle size of ceria particles is 0.7 μm.

[0031] Its production process is as follows: take 0.02kg of cerium dioxide particles and fill them into a mixing tank, collect them electrostatically, atomize and spray them into 4kg of diesel oil, 2kg of dimethyl carbonate, 0.5kg of propylene glycol and 3kg of biomass oil, and add 0.008kg of slow Etching agent, 0.012kg antioxidant and 0.01kg anti-swelling agent are mixed and stirred evenly, and the liquid slurry obtained is the oxygen-containing alcohol ester diesel fu...

Embodiment 2

[0033]An oxygen-containing alcohol ester diesel fuel, the raw material formula is: 60% of diesel oil, 15% of dimethyl carbonate, 10% of propylene glycol, 10% of biomass oil, 0.8‰ of cerium dioxide particles, corrosion inhibitor 0.2‰ agent, 2‰ antioxidant and 2‰ anti-swelling agent; wherein, the diesel oil is national standard diesel oil, the purity of dimethyl carbonate is 96%, the purity of propylene glycol is 97%, and the purity of biomass oil is 99%. %, the average particle size of ceria particles is 0.6 μm.

[0034] The production process is as in Example 1, and oxygen-containing alcohol ester diesel fuel is obtained.

Embodiment 3

[0036] An oxygen-containing alcohol ester diesel fuel, the raw material formula is: 30% of diesel oil, 10% of dimethyl carbonate, 7% of propylene glycol, 50% of biomass oil, 0.2‰ of cerium oxide particles, corrosion inhibitor agent 2‰, antioxidant 0.3‰ and anti-swelling agent 0.5‰; wherein, the diesel oil is national standard diesel oil, the purity of dimethyl carbonate is 97%, the purity of propylene glycol is 99%, and the purity of biomass oil is 100% %, the average particle size of ceria particles is 0.5 μm.

[0037] The production process is as in Example 1, and oxygen-containing alcohol ester diesel fuel is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com