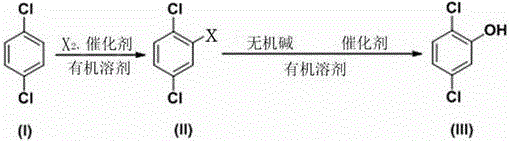

Synthesizing process of 2, 5-dichlorophenol

A technology for dichlorophenol and synthesis process, which is applied in the field of synthesis process of 2,5-dichlorophenol, can solve the problems of high industrialized production cost, environmental pollution, equipment corrosion, etc., and achieves reduction of the three-waste disposal amount and production cost. , the effect of short synthetic route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A kind of synthetic technique of 2,5-dichlorophenol, comprises the following steps:

[0036] A. Halogenation

[0037] Dissolve 1,4-dichlorobenzene in an organic solvent, add catalyst, add bromine at 30°C, react for 10 hours, remove residual bromine in the system, separate the organic phase, and concentrate and rectify the organic phase to obtain 2,5 -Dichlorobromobenzene; the molar ratio of bromine and 1,4-dichlorobenzene is 0.5:1, 2,5-dichlorobromobenzene conversion rate is 92.5%;

[0038] B. Hydrolysis

[0039] Dissolve the 2,5-dichlorobromobenzene obtained in step A in an organic solvent, add a copper salt catalyst, an inorganic base and water, react for 1 hour at a temperature of 150°C and a pressure of 1 MPa, and then pass the reaction liquid through alkali After washing, acidifying, extracting, and precipitation treatment, 2,5-dichlorophenol is obtained; the molar ratio of the inorganic base to 2,5-dichlorobromobenzene is 2:1, and the water and 2,5- The molar r...

Embodiment 2

[0042] A kind of synthetic technique of 2,5-dichlorophenol, comprises the following steps:

[0043] A. Halogenation

[0044] Dissolve 1,4-dichlorobenzene in an organic solvent, add catalyst, add bromine at 50°C, react for 6 hours, remove residual bromine, separate the organic phase, concentrate and rectify the organic phase to obtain 2,5- Dichlorobromobenzene; the molar ratio of bromine to 1,4-dichlorobenzene is 0.7:1, and the conversion rate of 2,5-dichlorobromobenzene is 95.3%;

[0045] B. Hydrolysis

[0046] Dissolve the 2,5-dichlorobromobenzene obtained in step A in an organic solvent, add a copper salt catalyst, an inorganic base and water, react for 3 hours at a temperature of 210°C and a pressure of 2 MPa, and then pass the reaction solution through alkali After washing, acidifying, extracting, and solvent removal, 2,5-dichlorophenol is obtained; the molar ratio of the inorganic base to 2,5-dichlorobromobenzene is 5:1, and the water and 2,5- The molar ratio of dichlo...

Embodiment 3

[0050] A kind of synthetic technique of 2,5-dichlorophenol, comprises the following steps:

[0051] A. Halogenation

[0052] Dissolve 1,4-dichlorobenzene in an organic solvent. After adding the catalyst, add iodine at 40°C. After reacting for 9 hours, remove the residual iodine, and separate the organic phase. The organic phase is concentrated and rectified to obtain 2,5- Dichloroiodobenzene; the molar ratio of the iodine to 1,4-dichlorobenzene is 0.6:1, and the conversion rate of 2,5-dichloroiodobenzene is 93.8%;

[0053] B. Hydrolysis

[0054] Dissolve the 2,5-dichlorobromobenzene obtained in step A in an organic solvent, add a copper salt catalyst and an inorganic base, react for 3 hours at a temperature of 180°C and a pressure of 1.5 MPa, and then wash the reaction solution with alkali , acidification, extraction, precipitation treatment to obtain 2,5-dichlorophenol; the molar ratio of the inorganic base to 2,5-dichloroiodobenzene is 4:1; 2,5-dichlorophenol hydrolysis yi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com