Preparation method of ultraviolet light absorber UV-PS

A UV-PS, ultraviolet technology, applied in the direction of organic chemistry, etc., can solve the problem of low yield of benzotriazole ultraviolet absorbers, achieve high yield, reduce environmental pollution, and increase yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

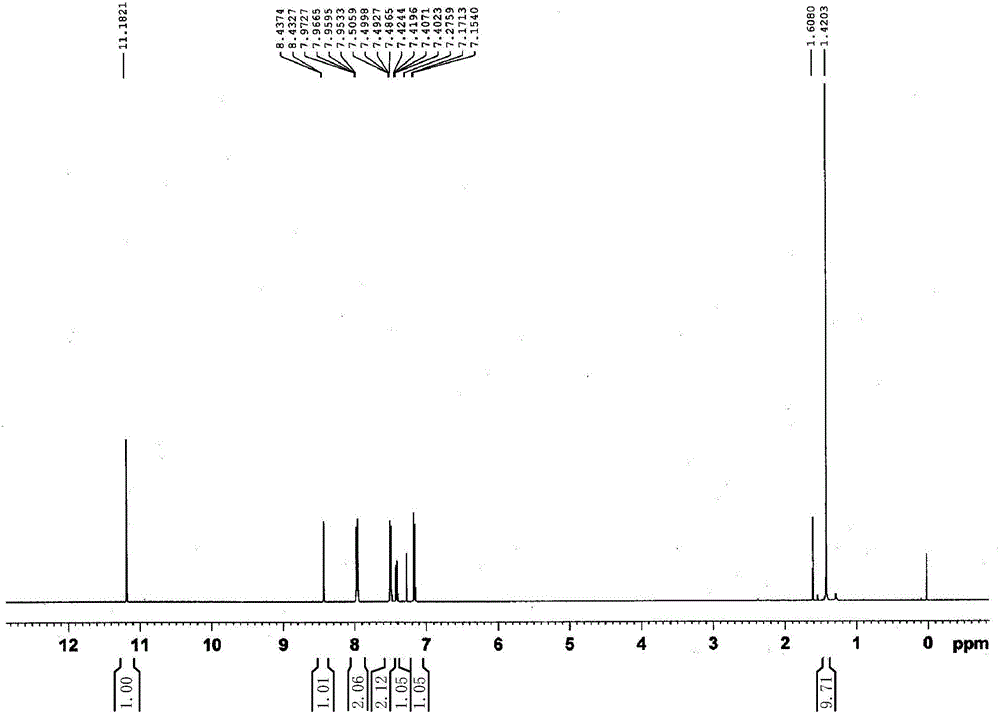

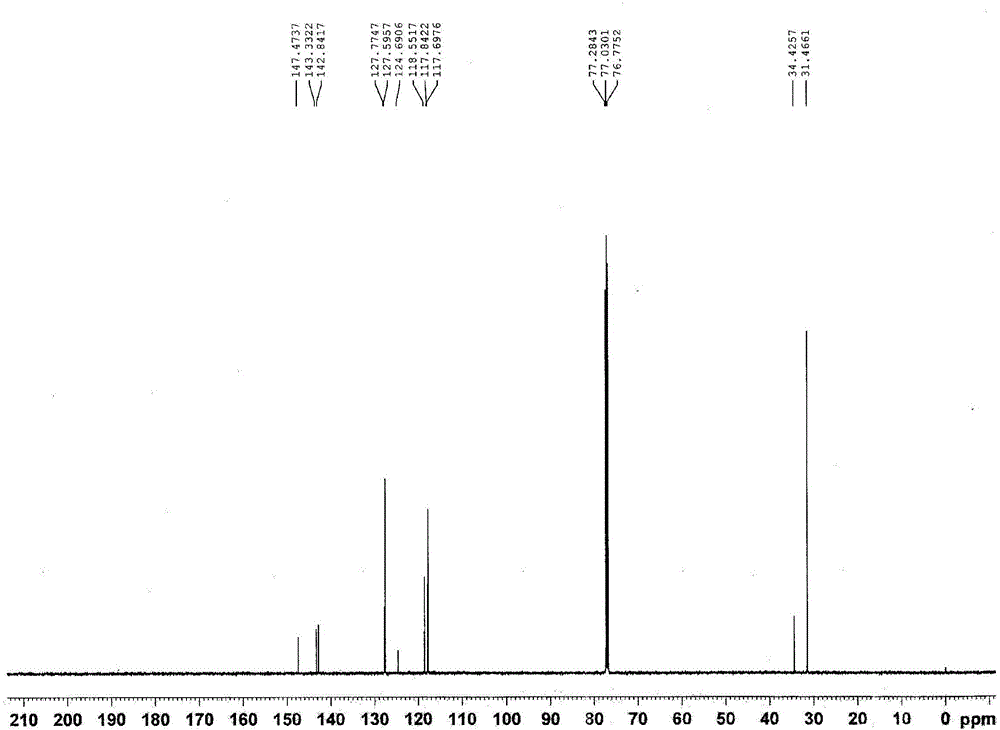

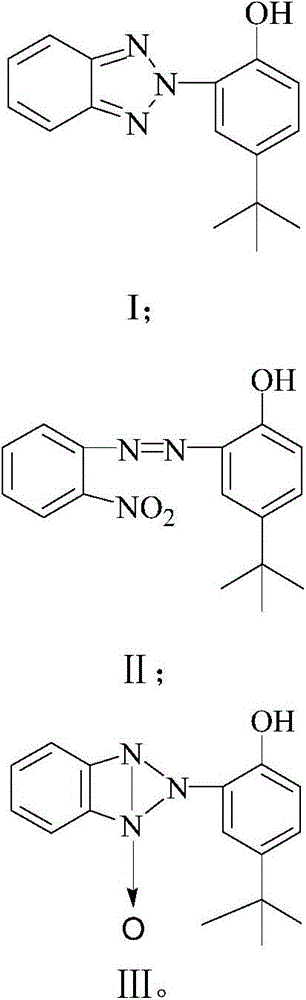

Image

Examples

example 1

[0034] Step S1, add 13.8g (0.1mol) of o-nitroaniline and 36.5g of 30% hydrochloric acid (0.3mol) into a 250ml three-necked flask with stirring, heat up to complete dissolution, add 40g of water, and cool down to below 0°C. Add 7.25g (0.105mol) sodium nitrite aqueous solution dropwise, keep warm for 2h after dripping, add 1g urea, eliminate excess sodium nitrite, filter to obtain diazonium salt solution;

[0035] Step S2. In a 500ml three-neck flask, add 50ml of toluene, add 2g of additives, add 15g (0.1mol) of p-tert-butylphenol, heat up to completely dissolve, then cool down to 15°C, dropwise add the aforementioned diazonium salt solution, and use Alkali controls the pH at 8, and keeps warm for 3 hours after dripping.

[0036] Step S3, heating up to evaporate toluene, and filtering to obtain 28.4 g (0.095 mol) of azo compound, with a yield of 95%;

[0037] Step S4, add 28.4g (0.095mol) of the above-mentioned azo compound, 10g (0.25mol) sodium hydroxide, 100ml water and 50ml ...

Embodiment 2

[0042] Step S1, add 13.8g (0.1mol) of o-nitroaniline and 36.5g of 30% hydrochloric acid (0.3mol) into a 250ml three-necked flask with stirring, heat up to complete dissolution, add 40g of water, and cool down to below 0°C. Add 10.4g (0.15mol) sodium nitrite aqueous solution dropwise, keep warm for 2h after dropping, add 1g urea, eliminate excess sodium nitrite, filter to obtain diazonium salt solution;

[0043]Step S2. In a 500ml three-neck flask, add 50ml of toluene, add 2g of additives, add 15g (0.1mol) of p-tert-butylphenol, heat up to completely dissolve, then cool down to 15-20°C, and dropwise add the aforementioned diazonium salt solution , use alkali to control the pH at 8-9, and keep it warm for 3 hours after dripping.

[0044] Step S3, heating up to distill toluene, and filtering to obtain 30.5 g (0.102 mol) of azo compound, with a yield of 95.1%;

[0045] Step S4, adding 30.5g (0.102mol) of the above azo compound, 10g (0.25mol) sodium hydroxide, 100ml water and 50ml...

Embodiment 3

[0050] Step S1, add 13.8g (0.1mol) of o-nitroaniline and 36.5g of 30% hydrochloric acid (0.3mol) into a 250ml three-necked flask with stirring, heat up to complete dissolution, add 40g of water, and cool down to below 0°C. Add 7.25g (0.105mol) sodium nitrite aqueous solution dropwise, keep warm for 2h after dripping, add 1g urea, eliminate excess sodium nitrite, filter to obtain diazonium salt solution;

[0051] Step S2. In a 500ml three-neck flask, add 50ml of toluene, add 2g of additives, add 15g (0.1mol) of p-tert-butylphenol, heat up to completely dissolve, then cool down to 15-20°C, and dropwise add the aforementioned diazonium salt solution , use alkali to control the pH at 8.5, and keep it warm for 3 hours after dripping.

[0052] Step S3, heating up to evaporate toluene, and filtering to obtain 28.4 g (0.095 mol) of azo compound, with a yield of 95%;

[0053] Step S4, add 28.4g (0.095mol) of the above-mentioned azo compound, 14g (0.25mol) potassium hydroxide, 100ml wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com