A silver paste containing spheroidized glass powder and a crystalline silicon solar cell made of the silver paste

A technology for spheroidizing glass powder and spheroidizing glass, applied in the field of solar cells, can solve the problems of uneven melting of glass powder, etc., and achieve the effects of improving photoelectric conversion efficiency, uniform and fine particles, and uniform melting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0034] Preparation of spheroidized glass powder: lead oxide, tellurium dioxide, bismuth trioxide, di Silicon oxide, zinc oxide, calcium oxide, lithium oxide, sodium oxide, copper oxide, molybdenum trioxide, tungsten trioxide, titanium dioxide and magnesium oxide are mixed evenly, heated and melted until clarified, poured into a tablet machine, cooled and pressed rapidly to form Glass flakes, the glass flakes are lightly hit to break the glass flakes, and the glass fine particles are obtained by airflow crushing. After cooling, the airflow enters the cyclone separator for classification, and the finished product is collected at the discharge port to obtain spheroidized glass powder.

Embodiment 1

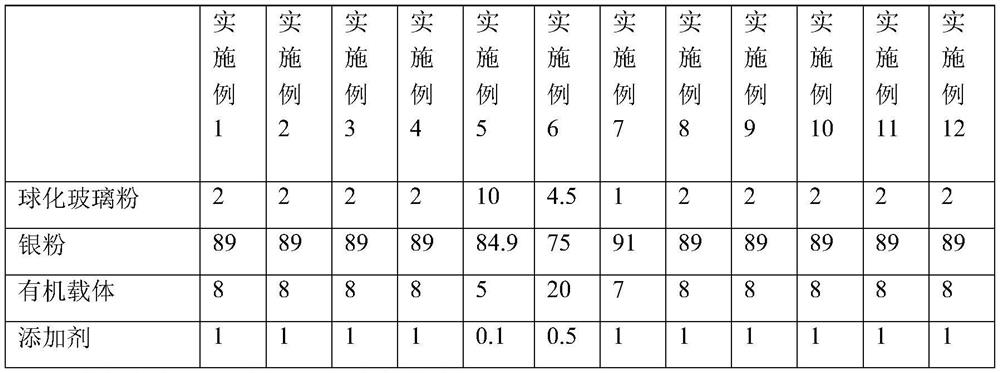

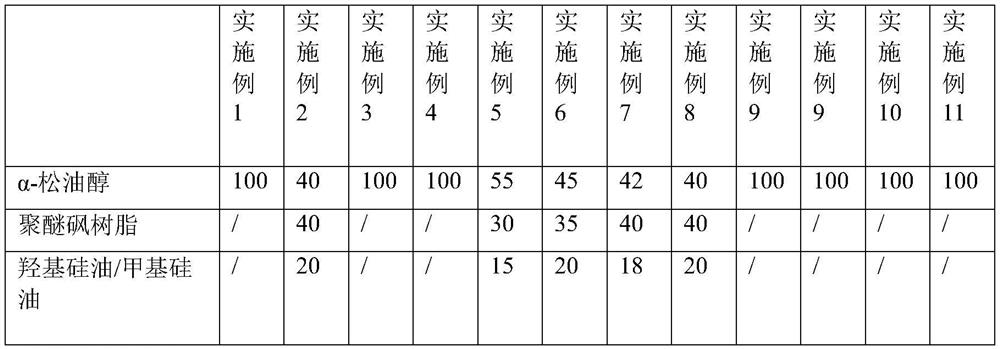

[0037] The application discloses a silver paste containing spheroidized glass powder, which includes the following raw materials: spheroidized glass powder, silver powder, organic carrier, additives, wherein the spheroidized glass powder adopts the spheroidized glass powder prepared in Preparation Example 1, organic The carrier is α-terpineol, the additive is polycarbonate diol, and the contents of each component are shown in Tables 1 and 2 below.

[0038] The crystalline silicon solar cell manufactured by using the above-mentioned silver paste, that is, use the above-mentioned silver paste on the battery substrate to screen-print and sinter the silver paste to obtain the front surface electrode and grid line of the solar cell panel, and obtain the desired solar cell.

Embodiment 2

[0040] The difference from Example 1 is that the organic carrier is a mixture of α-terpineol, polyethersulfone resin and hydroxyl silicone oil, and the contents of each component are shown in Tables 1 and 2 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com