A kind of bamboo-shaped carbon fiber and preparation method thereof

A carbon fiber and bamboo-like technology, which is applied in the field of carbon fiber materials and its preparation, can solve the problems of difficult control of carbon fiber structure dispersion uniformity, uncontrollable carbon fiber microstructure and morphology, and difficulty in realizing industrialized production, etc., and achieves low cost and bamboo joints. The effect of clear structure and uniform graphite dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] In the embodiment of this specification, the preparation method of bamboo-shaped carbon fiber comprises:

[0031] Preparation of precursor carbon source: dissolve benzoic acid and urea in a solvent, put them in a reaction kettle, transfer the reaction kettle to an oven for heating, and after the reaction, cool, centrifuge, wash and dry to obtain a precursor carbon source;

[0032] Carbonization: Put the precursor carbon source in a quartz boat, gradually heat up to the carbonization temperature, carry out carbonization under a constant temperature inert atmosphere, cool to room temperature, collect the solid phase, and obtain bamboo-shaped carbon fibers.

[0033] In the above method, the heating temperature is 60-140°C, preferably 80-120°C, more preferably 80°C. Wherein, the heating time is 5-7 hours, preferably 6 hours, and naturally cool after heating; in one embodiment, centrifugation is required before washing; the drying temperature is preferably 60°C. Benzoic aci...

Embodiment 1

[0035] Dissolve 1mmol of benzoic acid and 2mmol of urea in 20ml of N,N-dimethylformamide and 20ml of absolute ethanol respectively. After ultrasonically dissolving fully, mix them evenly and transfer them to the reactor. Transfer the reactor to 80°C After reacting in an oven for 6 hours, the reaction was stopped, cooled naturally to room temperature, centrifuged, washed, and dried at 60°C to obtain a precursor carbon source. Then put the precursor carbon source into the quartz boat, raise the temperature to 800°C at a rate of 5°C / min, and carbonize it in a nitrogen atmosphere at a constant temperature for 4 hours, then stop the reaction, cool naturally to room temperature, collect the solid phase, and obtain a bamboo-shaped carbon fiber.

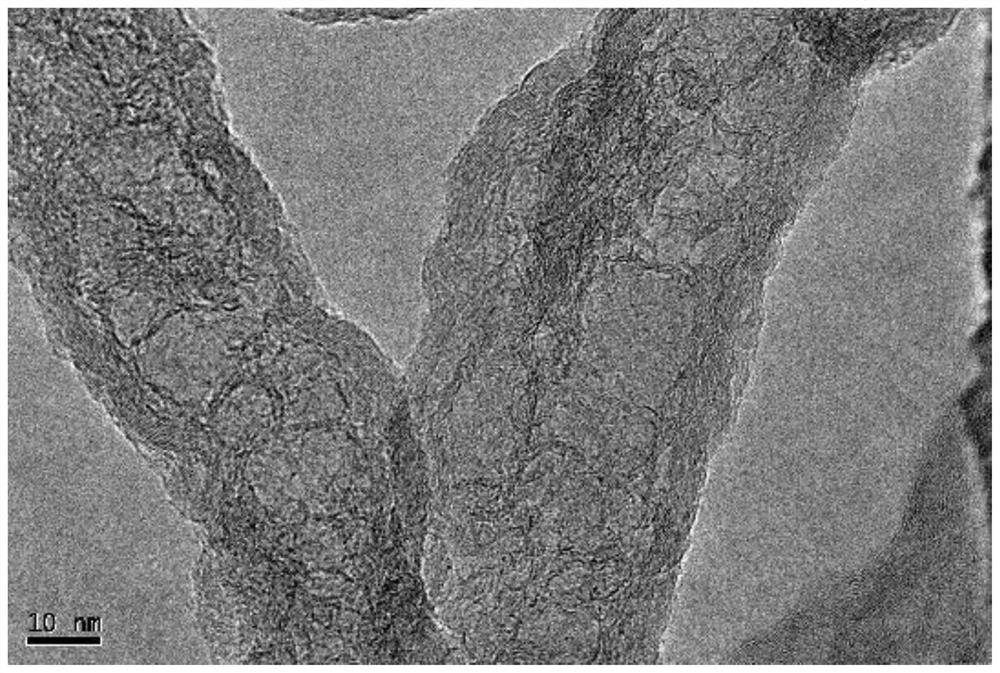

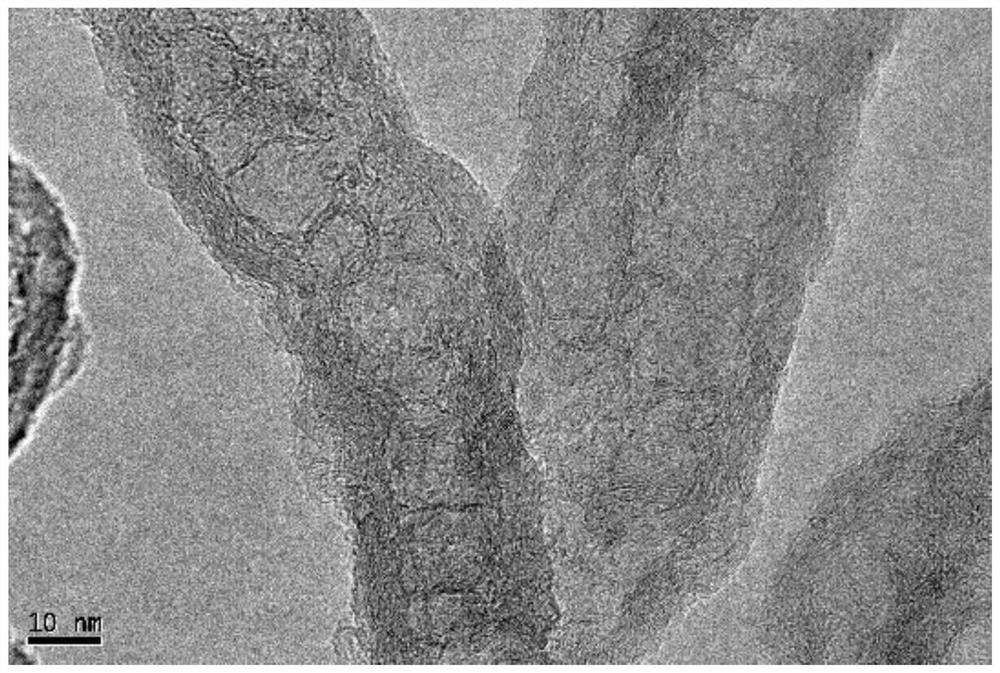

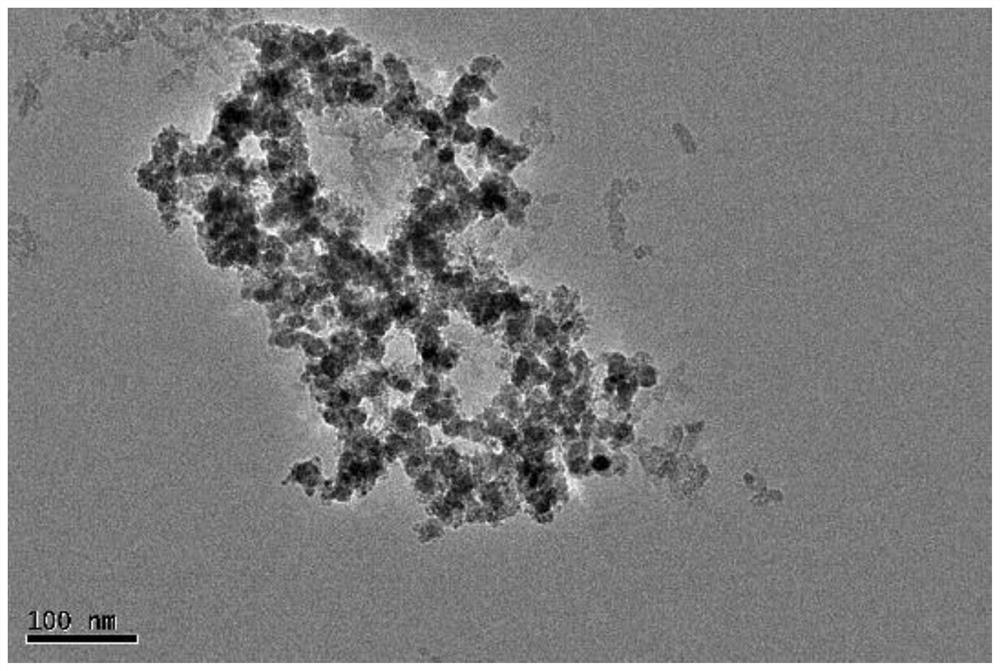

[0036] figure 1 and figure 2 Respectively, the transmission electron microscope of the obtained bamboo-shaped carbon fiber at a resolution of 10nm Figure I and TEM Figure II . Among them, the diameter of the carbon chain is about 30n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com