Three-dimensional porous sponge scaffold with meniscus matrix source and preparation method and application

A three-dimensional porous, meniscus technology, applied in the field of tissue engineering scaffolds, the preparation of tissue engineering scaffolds, and the field of scaffold products, can solve the problem that it is difficult to fully meet the special requirements of meniscus regeneration, affects the microenvironment of the damaged repair site, and is unfavorable for tissue reconstruction. Regeneration and other issues, to achieve good clinical application prospects, suitable degradation rate, simple and easy preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

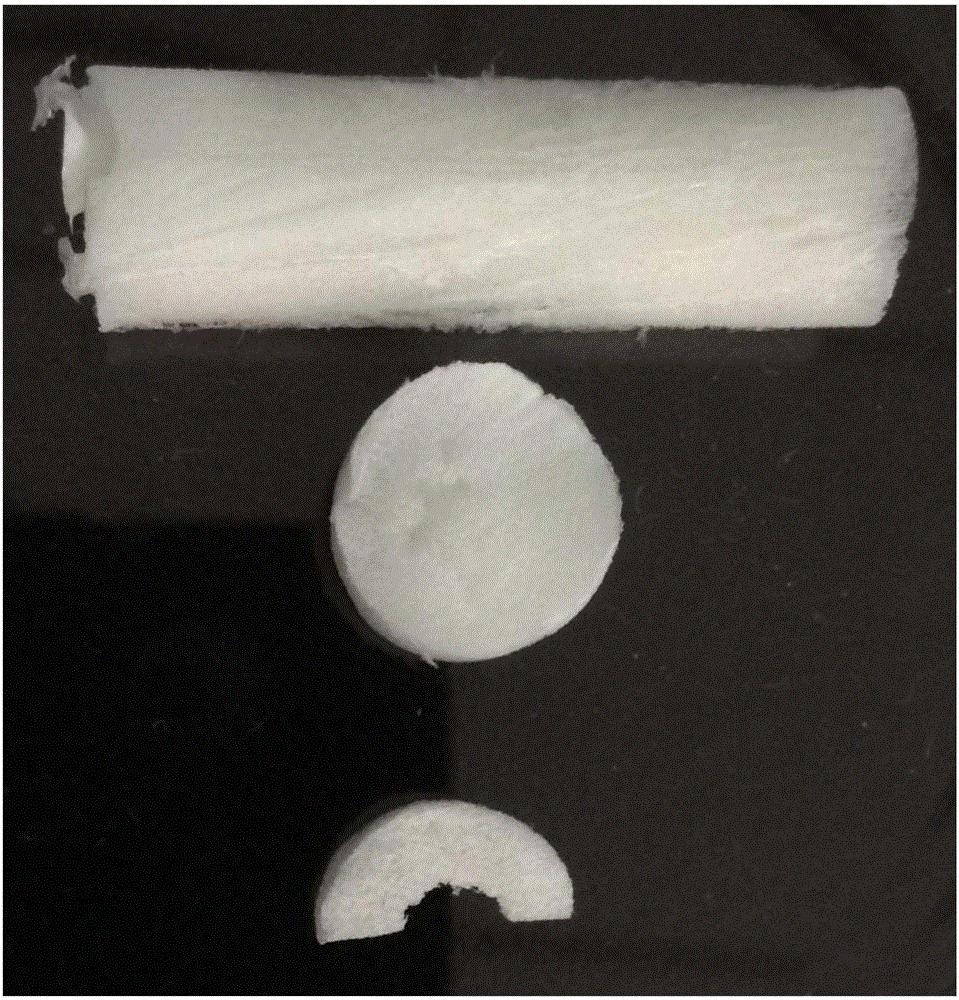

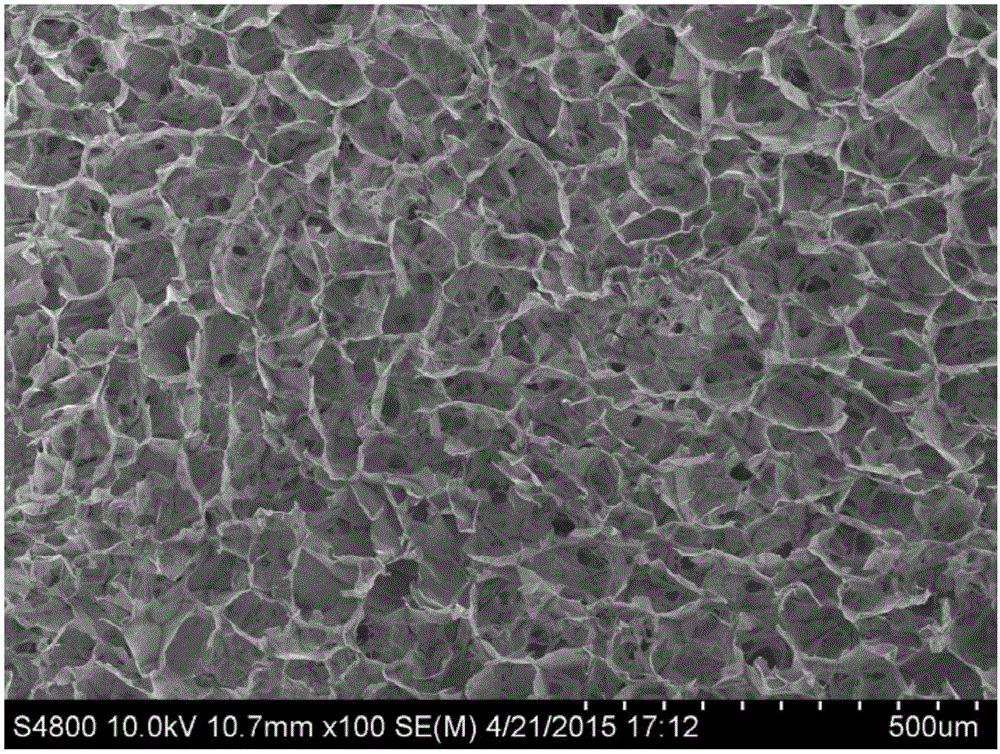

[0035] 1. Preparation of three-dimensional porous sponge-like scaffold derived from meniscus matrix:

[0036] 1. Take the meniscus of the pig, peel off the fat and synovial tissue under sterile conditions, cut the remaining tissue into pieces (5mm×5mm×5mm), wash it with distilled water for 3 times, then soak it in three-distilled water at ‐20°C, hypotonic Freeze and thaw 5 times, 5 hours each time, remove the triple distilled water after thawing, soak and stir with hydrogen peroxide for half an hour, and then rinse with distilled water 3 times, the volume ratio of hydrogen peroxide to tissue is 1:1, and the treatment time is 0.5 hours. It is to remove antigens such as red blood cells, make the tissue white and bulky, and help the cells in the tissue break down and prolapse.

[0037] 2. Add acetic acid and distilled water to the tissue, use the pH value of the solution (adjust the pH value to 1‐3) to control the ratio of acetic acid and distilled water, and then add 1% (weight ...

Embodiment 2

[0051] 1. Take the meniscus of the cow, peel off the fat and synovial tissue under aseptic conditions, cut the remaining tissue into pieces (5mm×5mm×5mm), rinse with distilled water for 3 times, then soak in three-distilled water at -10°C, hypotonic Freeze and thaw 4 times, 6 hours each time. After thawing, remove the triple distilled water, soak and stir in hydrogen peroxide for 1 hour, and then rinse with distilled water 3 times. The volume ratio of hydrogen peroxide to tissue is 1:2, and the treatment time is 1 hour.

[0052] 2. Add acetic acid and distilled water to the tissue, use the pH value of the solution (adjust the pH value to 1‐3) to control the ratio of acetic acid and distilled water, and then add 3% (weight percent) pepsin with a volume ratio of 2:1 solution, then pour it into a pulverizer, and pulverize it in a low-temperature chromatography cabinet for 10 minutes to make a homogenate. The time for each pulverization should not exceed one minute, and each pulver...

Embodiment 3

[0059] 1. Take the meniscus of the sheep, peel off the fat and synovial tissue under sterile conditions, cut the remaining tissue into pieces (5mm×5mm×5mm), wash it with distilled water for 3 times, then soak it in three-distilled water at -40°C, hypotonic Freeze and thaw 3 times, 4 hours each time. After thawing, remove the triple distilled water, soak and stir in hydrogen peroxide for half an hour, and then rinse with distilled water 3 times. The volume ratio of hydrogen peroxide to tissue is 1:3, and the treatment time is 45 minutes.

[0060] 2. Add acetic acid and distilled water to the tissue, use the pH value of the solution (adjust the pH value to 1‐3) to control the ratio of acetic acid and distilled water, and then add 5% (weight percent) pepsin with a volume ratio of 2:1 solution, then pour it into a pulverizer, and pulverize it in a low-temperature chromatography cabinet for 15 minutes to make a homogenate. The time for each pulverization should not exceed one minute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com