Extracting method for lead in silver separating residues

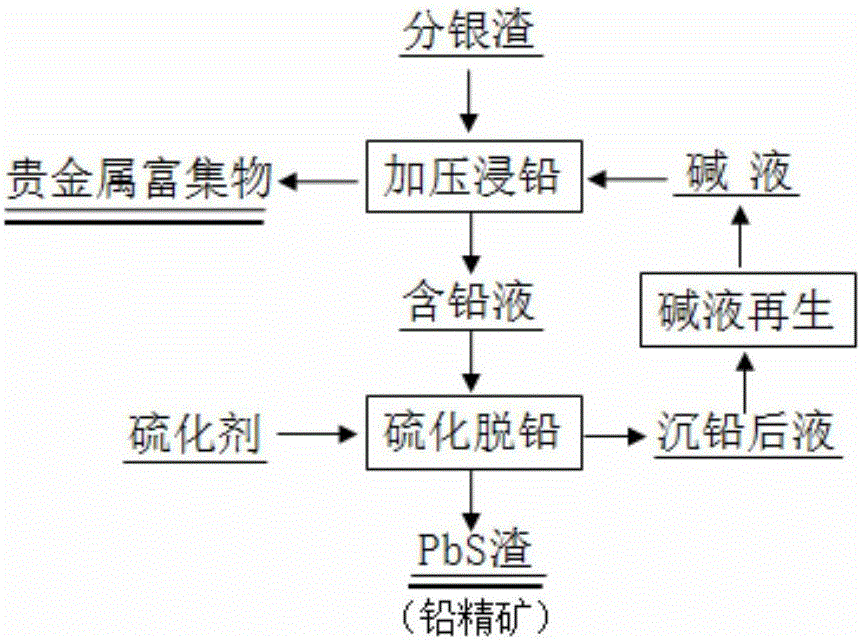

An extraction method and silver slag separation technology are applied in the field of lead extraction from silver slag separation, which can solve the problems of cumbersome process, low lead leaching rate, and long production cycle, so as to reduce alkali consumption, increase reaction rate, and improve The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0017] Get 1kg of silver slag as raw material, control the liquid-solid ratio to be 10:1, OH - The spent alkali solution with a concentration of 2.0 mol, a pressure of 2.0 atmospheres, a reaction temperature of 110° C., a stirring speed of 100 rpm, and a lower reaction time of 0.5 hours. After the reaction was completed, the lead-containing leachate and precious metal enrichment were obtained by filtration and separation. The leaching rate of lead is 92.1%; Na 2 The amount of S is 1.05 times of the amount of theoretically generated lead sulfide. After filtration and separation, lead sulfide slag with a lead content of 62.9% is obtained. The composition meets the industry standard for secondary lead concentrate (YST 319-2013). Sulphate ion, the add-on of lime is 10g / L, and the regenerated lye is used as the lead leaching mother liquor of example 2.

example 2

[0019] Get 1kg of silver slag as raw material, take the regenerated lye in example 1 as leaching mother liquor, control liquid-solid ratio is 8:1, and pressure is 2.5 atmospheres, and reaction temperature is 115 ℃ of temperature, and stirring speed is 150 rev / mins, React for 1.0 hour, filter and separate to obtain lead-containing leachate and precious metal enrichment after the reaction finishes, and the leaching rate of lead is 92.6%,; Lead-containing leachate K 2 The amount of S added is 1.1 times the amount of theoretically generated lead sulfide. After filtration and separation, lead sulfide slag with a lead content of 65.9% is obtained. The composition meets the industry standard for secondary lead concentrate (YST 319-2013). Sulphate ion, the add-on of lime is 20g / L, and regeneration lye is used as the immersion lead mother liquor of example 3.

example 3

[0021] Get 1kg of silver slag as raw material, take regenerated lye in example 2 as leaching mother liquor, control liquid-solid ratio is 6:1, pressure is 3.5 atmospheres, temperature of reaction is 125 ℃ of temperature, and stirring speed is 200 rev / mins, Reaction 0.5 hour, filter separation after reaction finishes and obtain lead-containing leachate and precious metal enrichment, the leaching rate of lead is 94.7%,; Lead-containing leachate (NH 4 ) 2 The amount of S added is 1.2 times the amount of theoretically generated lead sulfide. After filtration and separation, lead sulfide slag with a lead content of 65.4% is obtained. The composition meets the industry standard for secondary lead concentrate (YST 319-2013). Sulphate ion, the addition of lime is 30g / L, and regenerated lye is standby.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com